Intra-mode automatic screw inserting machine

A screw machine and screw technology, applied in the direction of coating, etc., can solve the problems that affect the continuity and stability of product quality, and the length of production cycle is different, so as to achieve stable production cycle and quality factors, reduce labor input, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

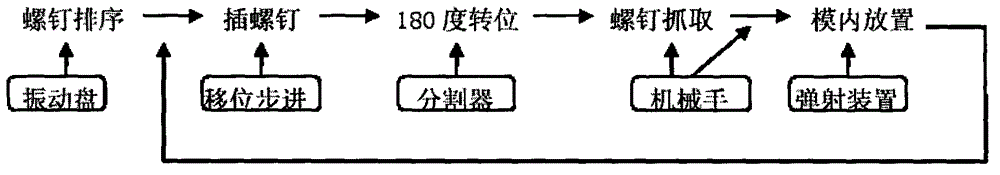

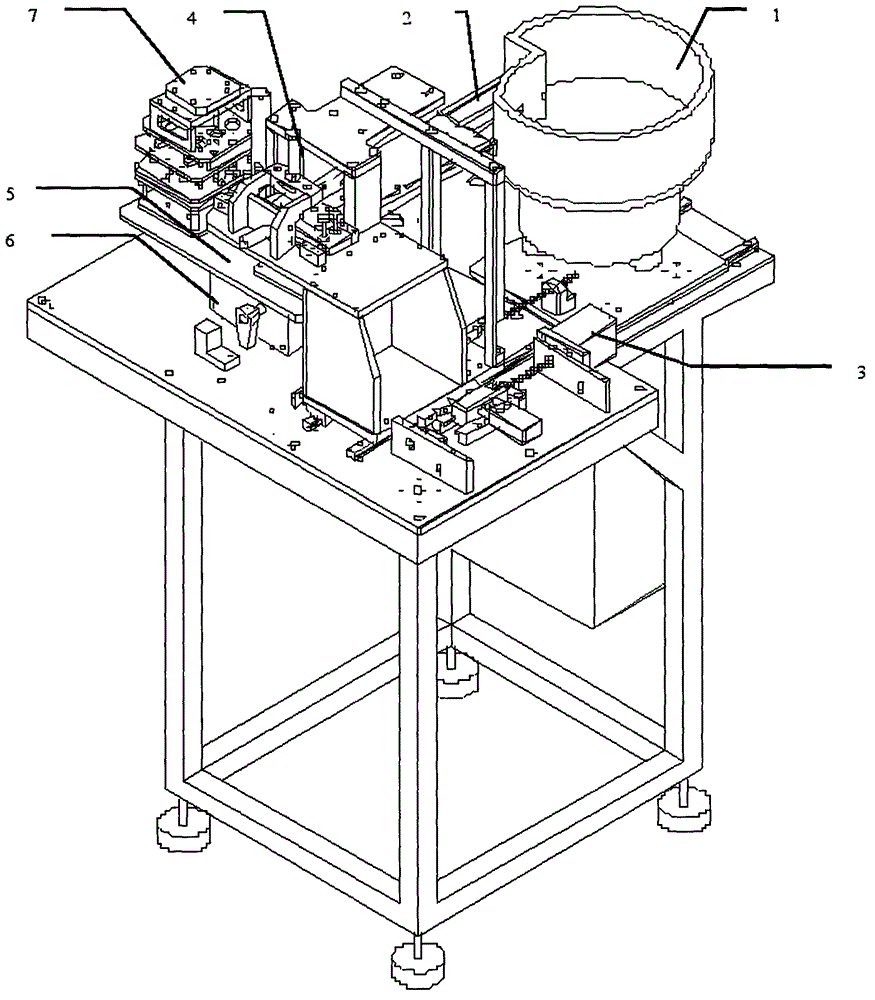

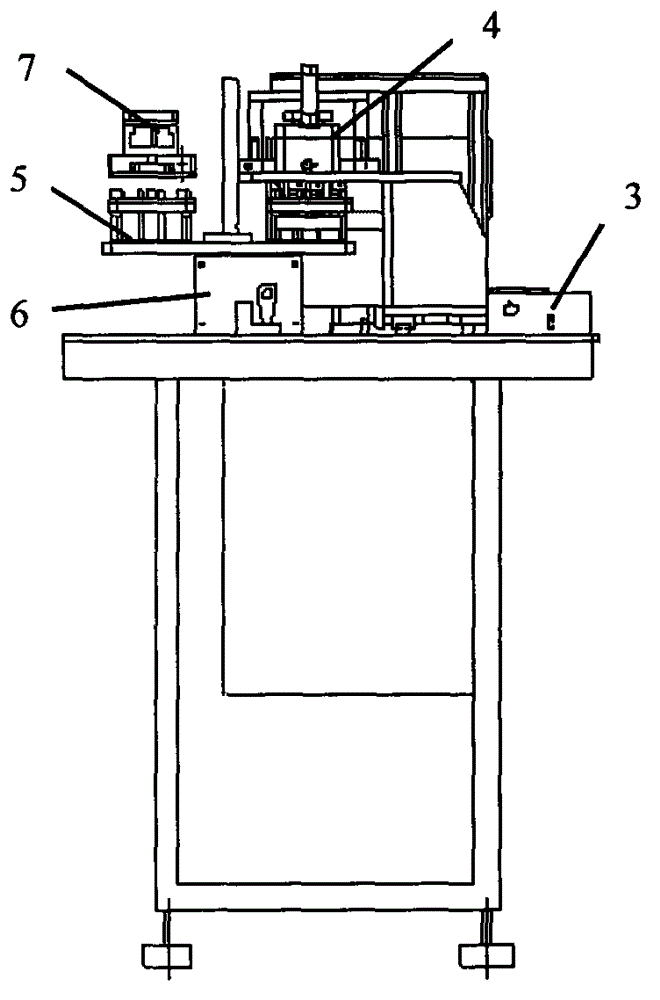

[0035] Referring to the accompanying drawings, the present invention is an automatic screw inserting machine in a mold, which is characterized in that it includes a vibrating plate 1, a guide groove 2, a shifting step mechanism 3, a screw insertion mechanism 4, a rotating plate 5, and a divider connected in sequence 6. The manipulator (not shown in the figure) and the ejection device 7, the vibration plate 1 is connected with the displacement stepping mechanism 3 through the guide groove 2, and the vibration of the vibration plate 1 sends the screw along the guide groove 2 to the displacement stepping mechanism 3 , the displacement stepping mechanism 3 displaces the screw to the screw insertion mechanism 4, the screw insertion mechanism 4 places the screw on the rotating plate 5, the divider 6 rotates the rotating plate 5 by 180 degrees, and the rotating plate 5 puts the screw on Enter the ejection device 7, the manipulator takes away the ejection device 7 with the screw, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com