Supporting seat of punching machine

A stamping machine tool and support seat technology, which is applied in the direction of presses, manufacturing tools, etc., can solve problems such as the influence of machining accuracy, uneven worktables of stamping machine tools, and unstable connection methods, so as to achieve the effect of reducing the level and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

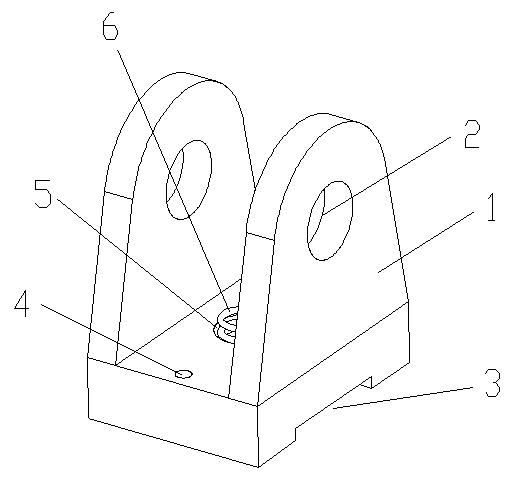

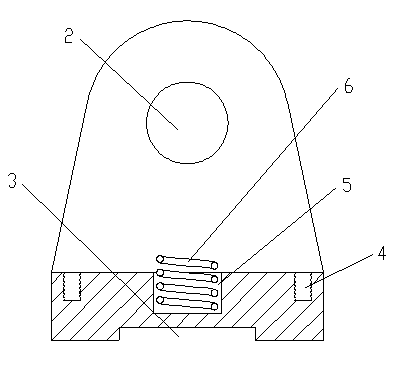

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 , 2 The shown support base of a stamping machine tool according to the present invention includes a support base body 1; the support base body 1 is in the shape of a "U"; a positioning hole 2 is opened on the side wall of the support base body 1; The lower end surface of the support seat body 1 has a strip-shaped through groove 3; the support seat body 1 is symmetrically provided with a group of positioning threaded holes 4 near the upper and lower ends; the center of the support seat body 1 has a round hole 5; An elastic shock-absorbing body 6 is arranged inside the round hole 5; the elastic shock-absorbing body 6 is a damping spring.

[0014] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0015] The stamping machine tool support seat of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com