Riding work machine

A technology for working machines and transmission mechanisms, applied in steering mechanisms, control devices, transportation and packaging, etc., can solve problems such as low installation freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

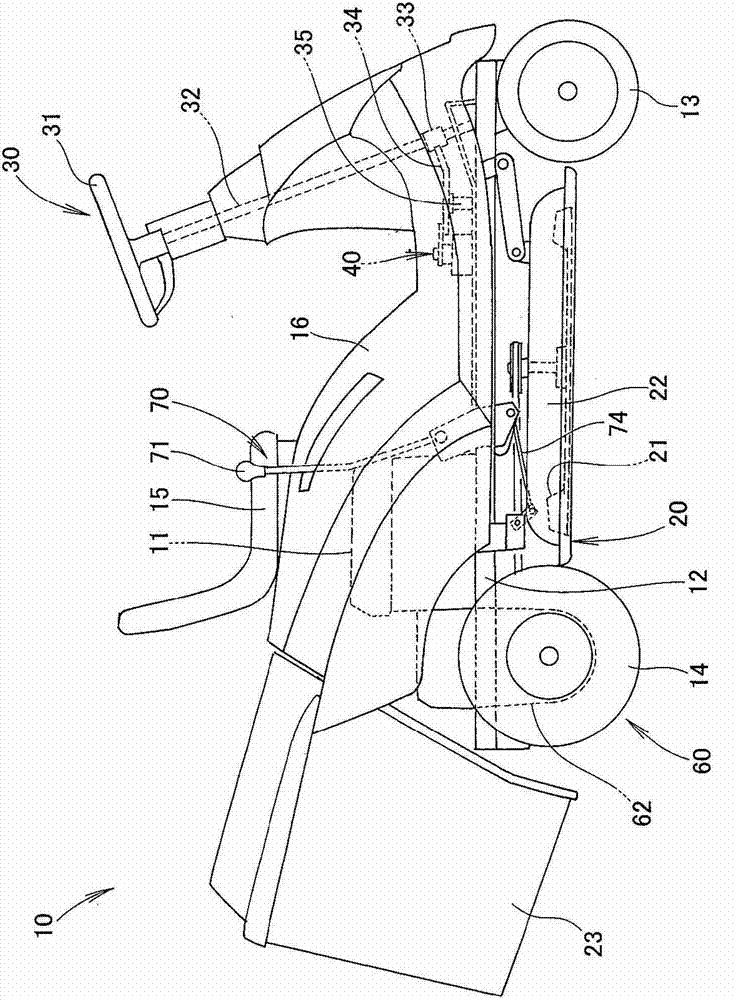

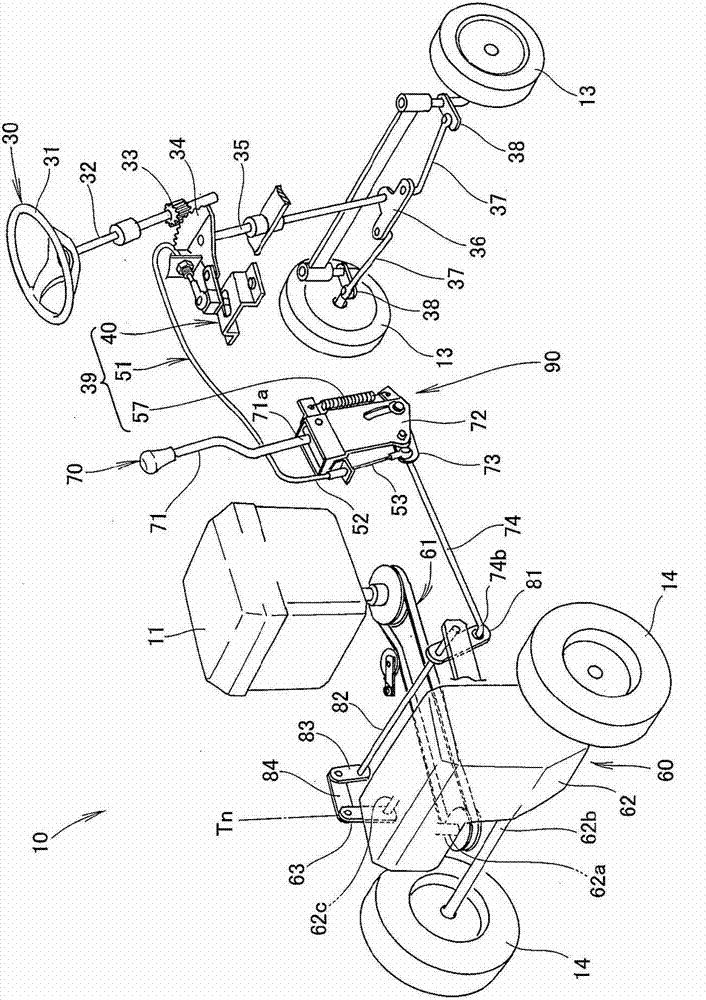

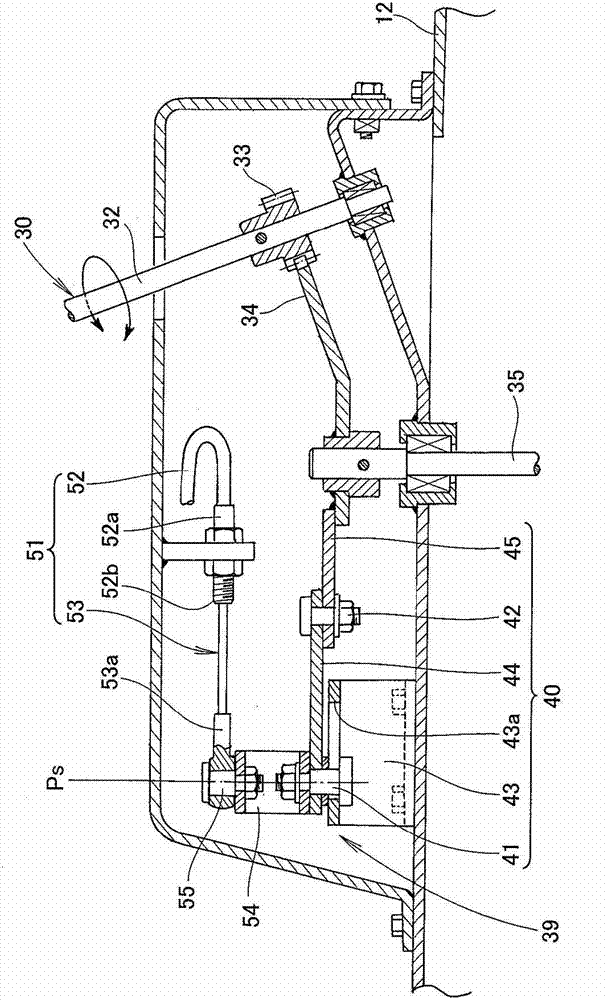

[0035] Such as figure 1 , 2 As shown, the riding work machine 10 includes a working system 20 , a steering system 30 and a traveling system 60 . The working machine 10 is driven by a single engine 11 together with a working system 20 . Specifically, the engine 11 drives the working system 20 through one belt, and drives the traveling system 60 through another belt. In this embodiment, the working system 20 includes a mowing unit.

[0036]The engine 11 is installed on the upper part of the rear part of the machine body 12 of the working machine 10 . The body 12 is equipped with left and right front wheels 13,13 and left and right rear wheels 14,14. The front wheels 13 and 13 are steered by a steering wheel 31 mounted on the front of the body 12 . The rear wheels 14, 14 are driving wheels driven by the output power of the engine 11.

[0037] Such as figure 1 As shown, the mowing part of the handling system 20 is arranged below the middle part of the machine body 12 and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com