Non-excavation correction method and apparatus of pipeline center line deviation after pipe-jacking construction

A centerline, non-excavation technology, applied in the direction of pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of low overall availability, low safety factor, difficult operation, etc., to achieve strong availability, The effect of high technical requirements and low resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

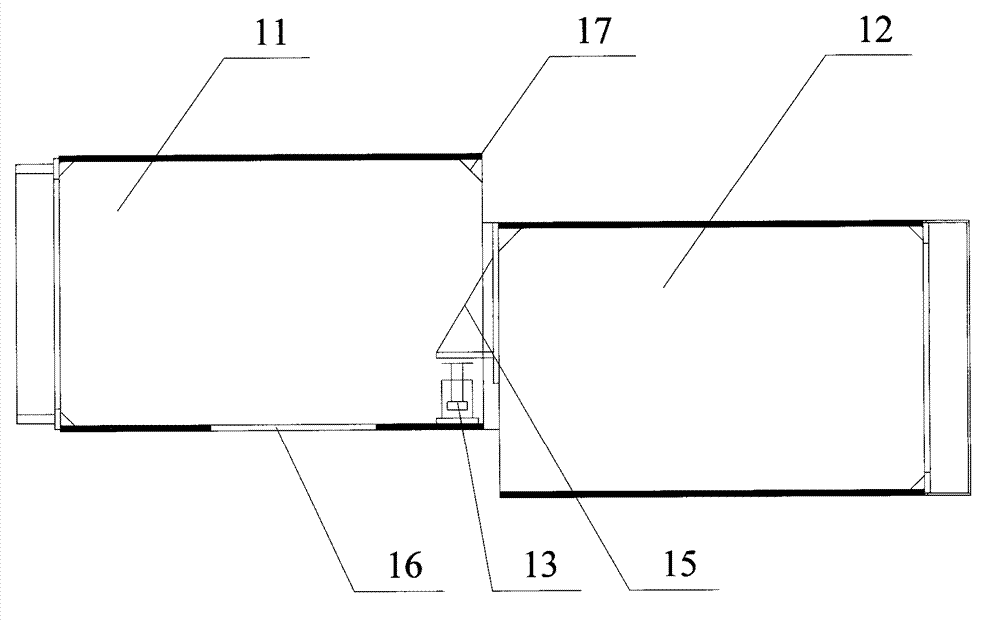

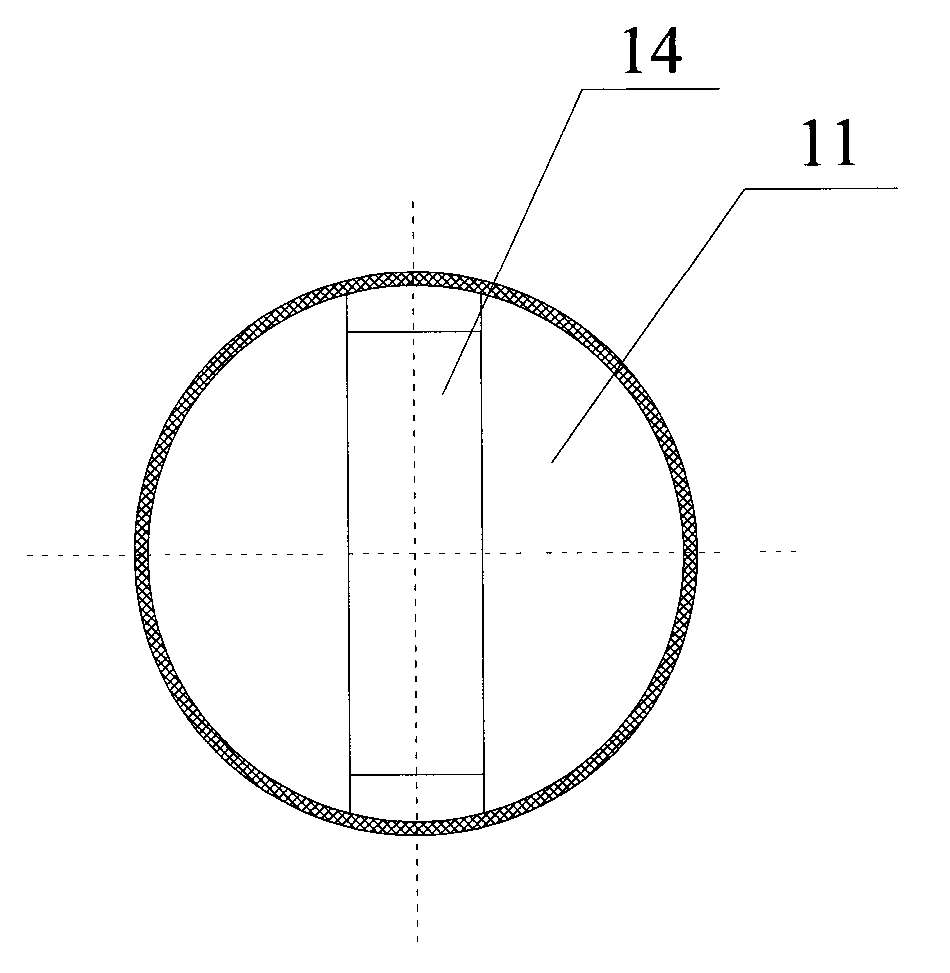

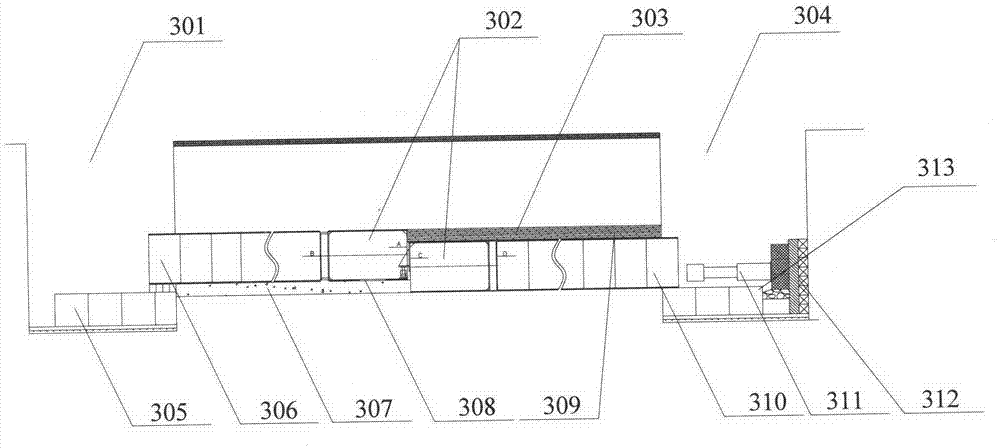

[0032] Such as Figure 1-Figure 2 As shown, they are respectively the side view of the embodiment of the trenchless correction device for pipeline centerline deviation of the present invention and the rear view of the front casing. It should be noted, figure 1 Shown is the correction processing equipment for the high centerline of the pipeline, and the processing equipment with the low centerline, left, and right is similar to the structure shown in the figure, and will not be repeated here. The trenchless correction equipment for pipeline centerline deviation of this embodiment includes a front housing 11, a rear housing 12, and a lifting adjustment device 13, and the front housing 11 and the rear housing 12 are both cylindrical. Where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com