DC electric power system used for converter accident tilting, and oxygen sublance accident lifting

A technology of DC power supply and power system, applied in emergency power supply arrangement, current collector, electric vehicle and other directions, can solve the problems of complicated design and manufacture, heavy workload, easy to cause failure, etc., and achieve easy installation and debugging, low price, The effect of simplifying mechanical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

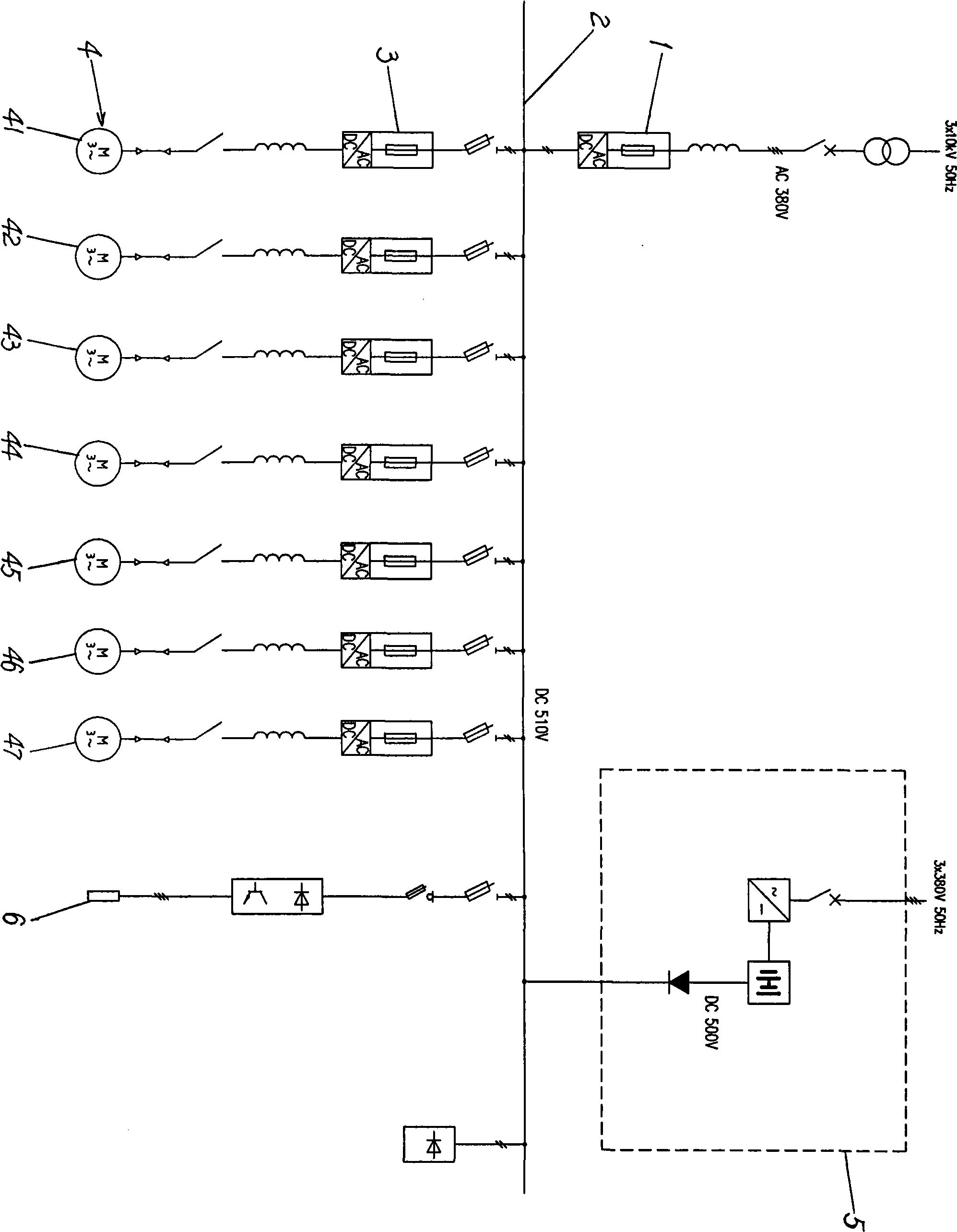

[0026] Referring to the accompanying drawings, the present invention is a DC power supply power system used for converter accident tilting and oxygen auxiliary lance accident lifting. The tilting of the converter and the lifting of the oxygen sub-lance adopt AC frequency conversion speed control device, and adopt the scheme of public DC bus.

[0027] The AC power supply of the system is connected to the rectifier 1, which converts the AC power into DC power, and through the common DC bus 2, several inverters 3 are connected to the DC bus 2, and each inverter 3 drives the connected motor 4 respectively. Among the figure, label 41 is the No. 1 tilting motor, 42 is the No. 2 tilting motor, 43 is the No. 3 tilting motor, 44 is the No. 4 tilting motor, 45 is the first oxygen lance, 46 is the second oxygen lance, and 47 is the auxiliary gun.

[0028] The DC power supply 5 is connected to the DC bus 2 of the inverter through a high-power diode. The voltage of the DC power supply 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com