Artificial shoulder joint prosthesis

A shoulder joint and prosthesis technology, applied in the field of artificial shoulder joint prosthesis, can solve the problems of poor anatomical adaptability, unable to satisfy the continuous adjustment of the prosthesis at the same time, unable to realize the anatomical reconstruction of the proximal humerus, etc., and achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

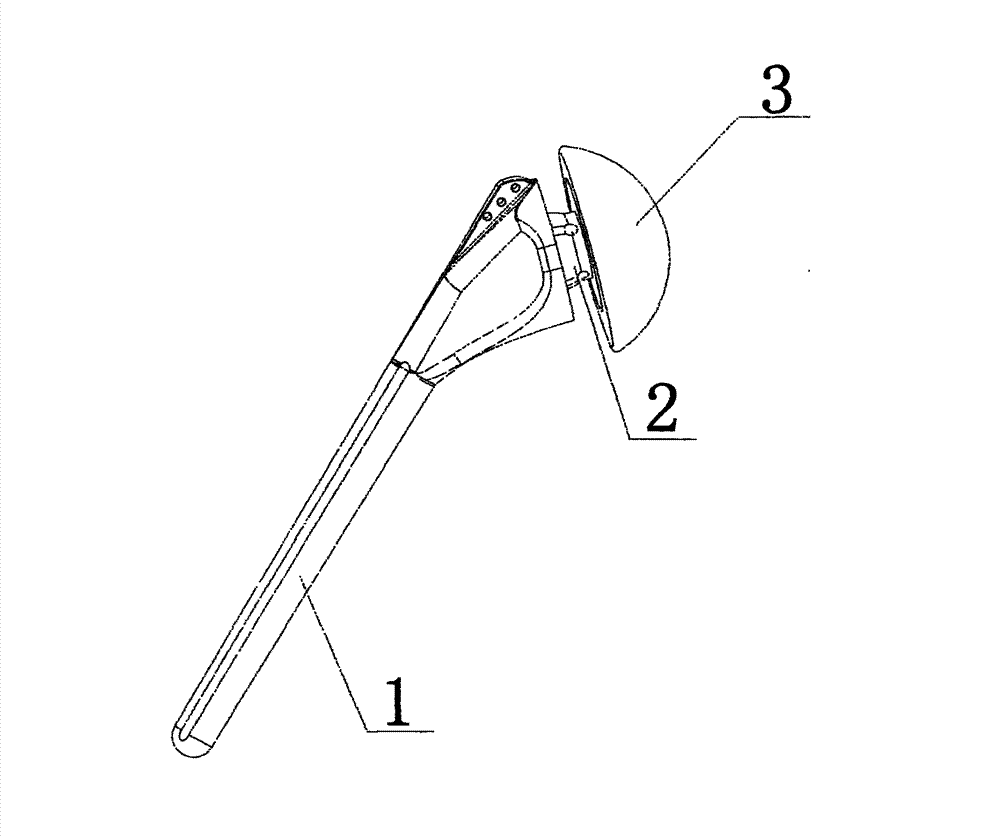

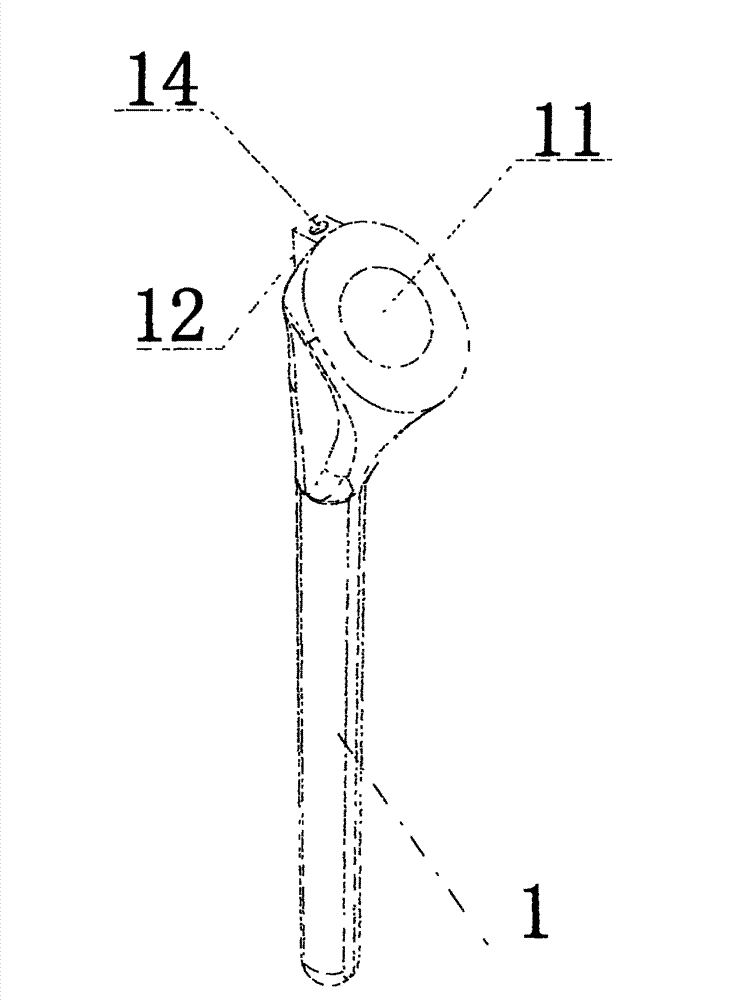

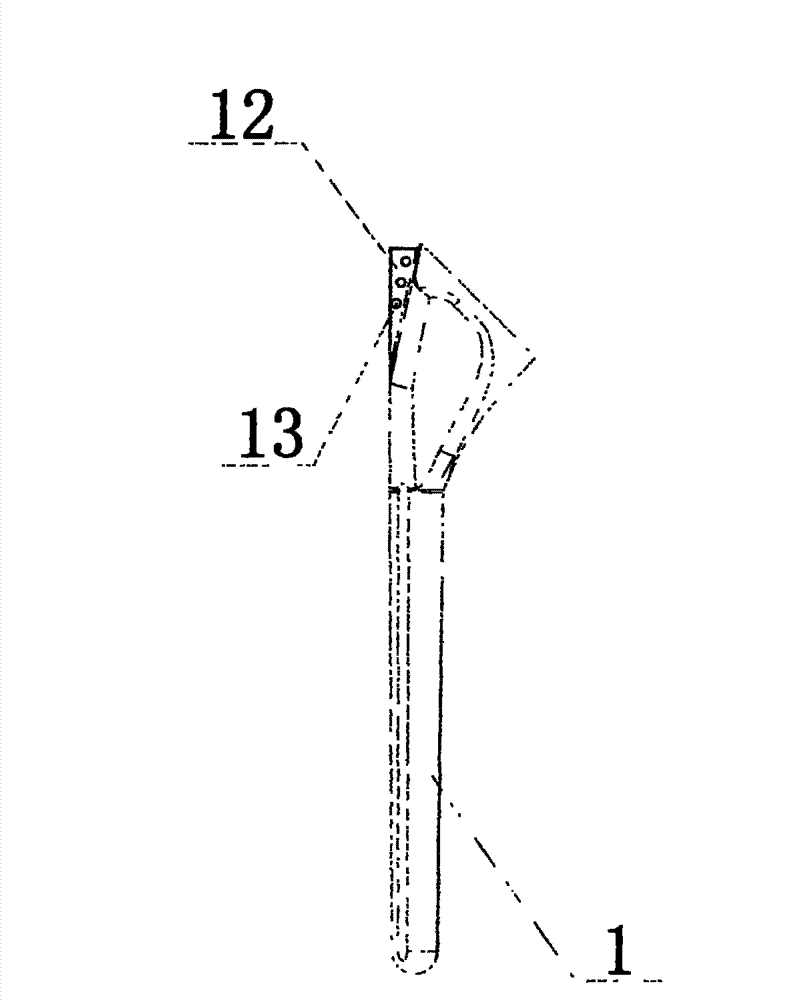

[0016] Embodiment: The metal materials used in the manufacture of the present invention are medical titanium and titanium alloys, or medical cobalt-chromium-molybdenum alloys. refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , an artificial shoulder joint prosthesis, comprising a prosthesis stem 1, a connecting neck 2 and a prosthesis head 3, the upper end surface of the prosthesis stem 1 is consistent with the inclination angle of the patient's humerus osteotomy surface, and a ball socket 11 is arranged in the middle of the upper end surface , the back of the upper end surface is provided with a ridge 12, and the top surface of the ridge 12 is provided with a holding hole 14, and the holding hole 14 has an internal thread, which can be screwed in for the holder; there are three rotator cuff suture holes 13 on the side of the ridge 12, Used to suture the rotator cuff tendon.

[0017] The connecting neck 2 is an integrally formed connecting column 23, tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com