Patents

Literature

51 results about "Prosthesis design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

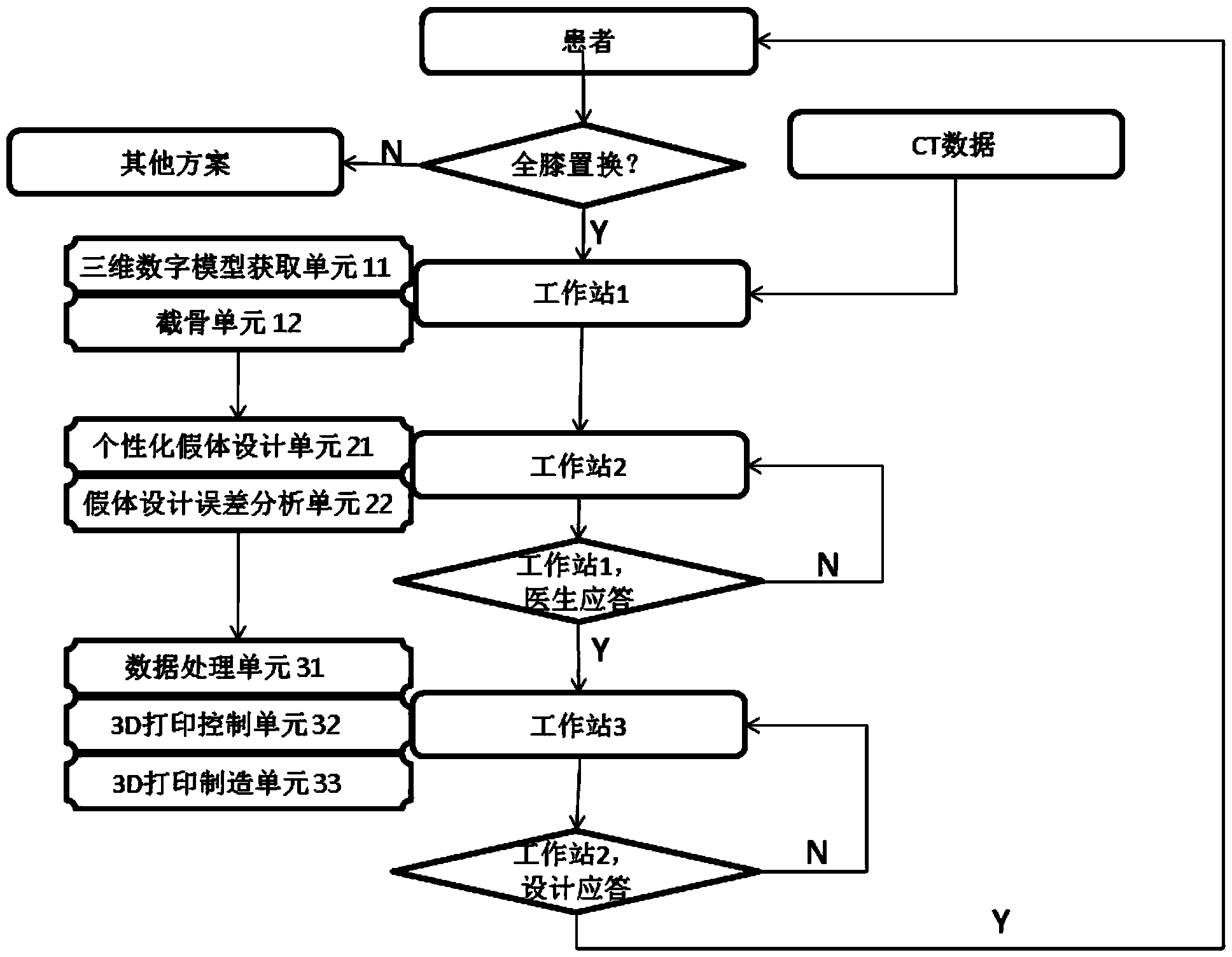

Individualized design and manufacturing system and method for full knee joint replacing prosthesis

InactiveCN103860294AImprove matchGet rid of the trouble of not matching the structure of the knee joint wellJoint implantsKnee jointsPersonalizationManufacturing technology

The invention relates to an individualized design and manufacturing system and an individualized design and manufacturing method for a full knee joint replacing prosthesis. Through three work stations set in different places, doctors, design personnel and engineering personnel are connected, in addition, the image processing technology, the virtual operation planning, the information communication, the individualized interaction design, the product performance fast analysis and the 3D (three-dimensional) printing manufacturing technology are merged, through the system, the doctors can know the design and manufacturing conditions of the knee joint prosthesis at any time, the design personnel can design the personnel applicable prosthesis according to the knee joint form of a patient and can modify the prosthesis design at any time according to the scheme of the doctors, finally, the engineering personnel use the 3D printing technology for manufacturing the designed prosthesis, and the individualized knee joint prosthesis best matched with the knee joint of the patient is produced, so the optimum matching between the prosthesis and the knee joint is ensured on the basis of minimum bone cutting quantity, and the effect optimization is realized. The system and the method have the advantages that the trouble that the existing prosthesis product cannot be better matched with the knee joint structure can be avoided, in addition, the individualized and customized replacing operation scheme for the patient becomes possible, and great significance is realized in the medical field.

Owner:PEKING UNIV THIRD HOSPITAL +1

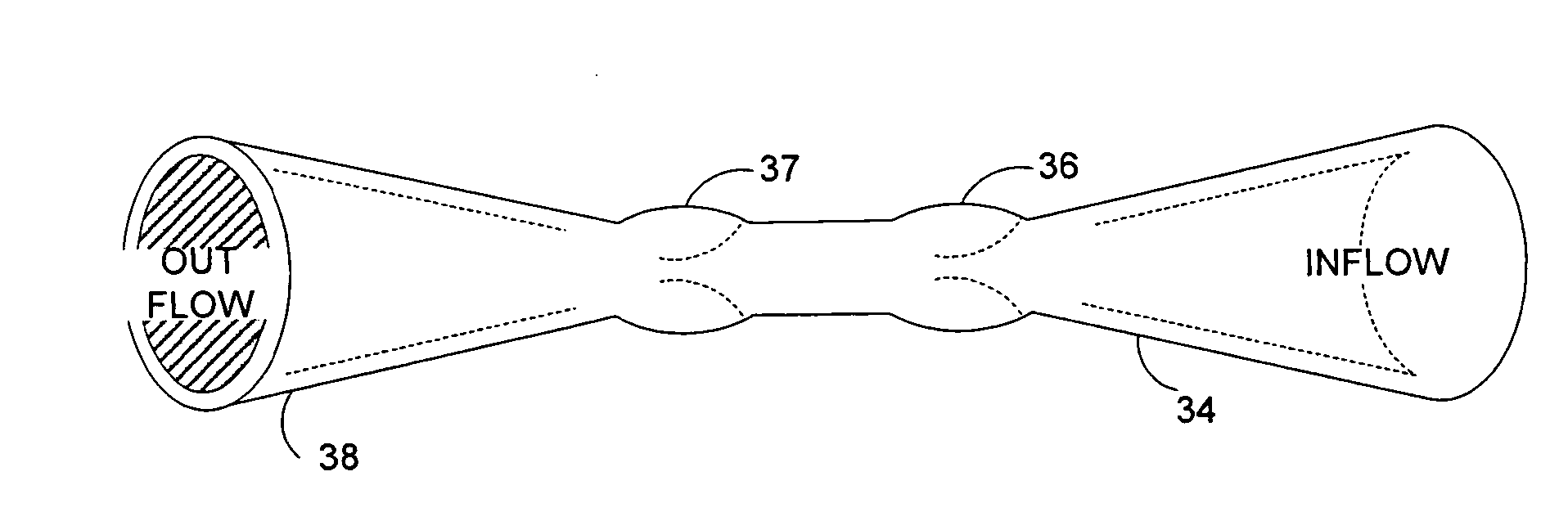

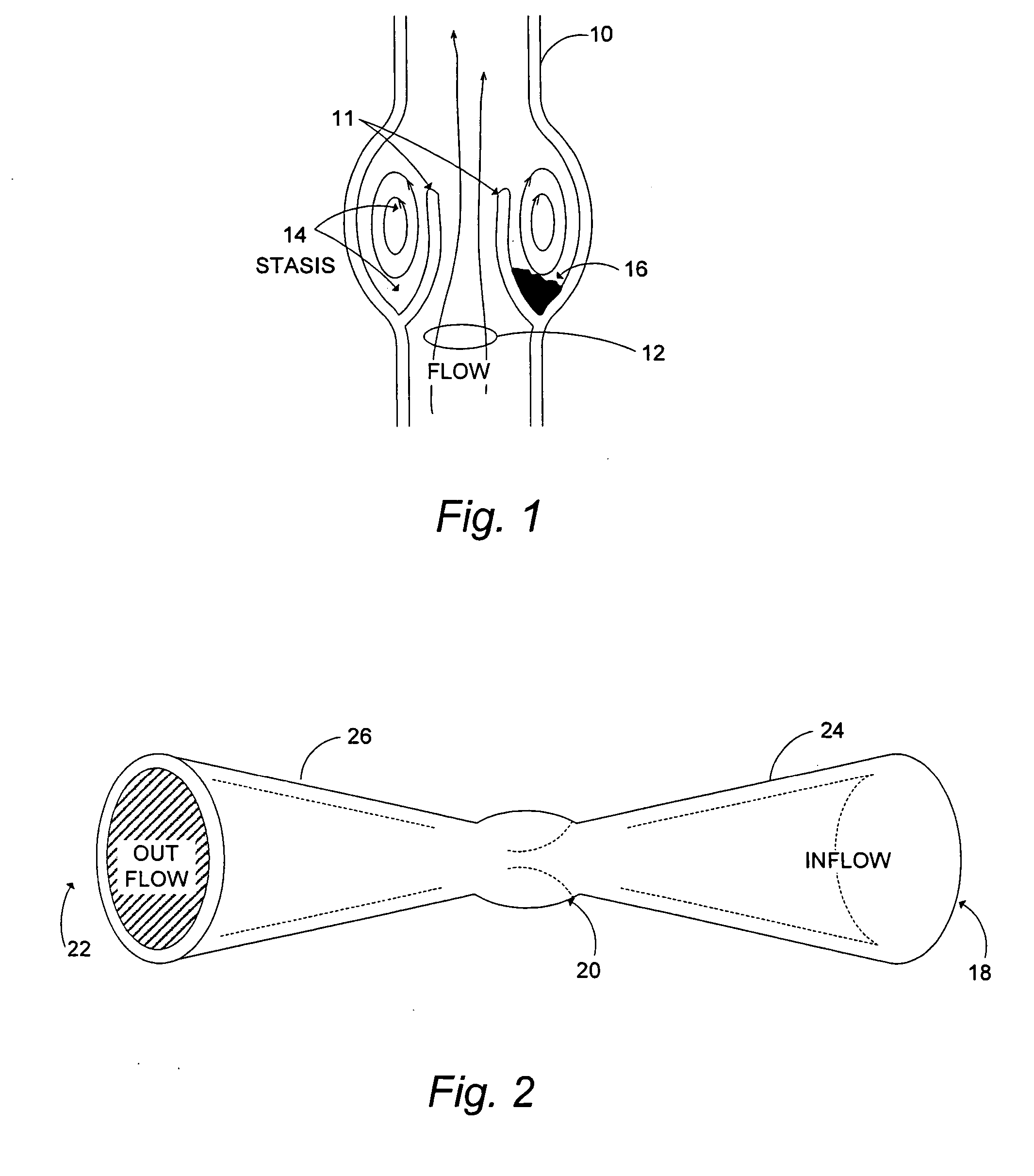

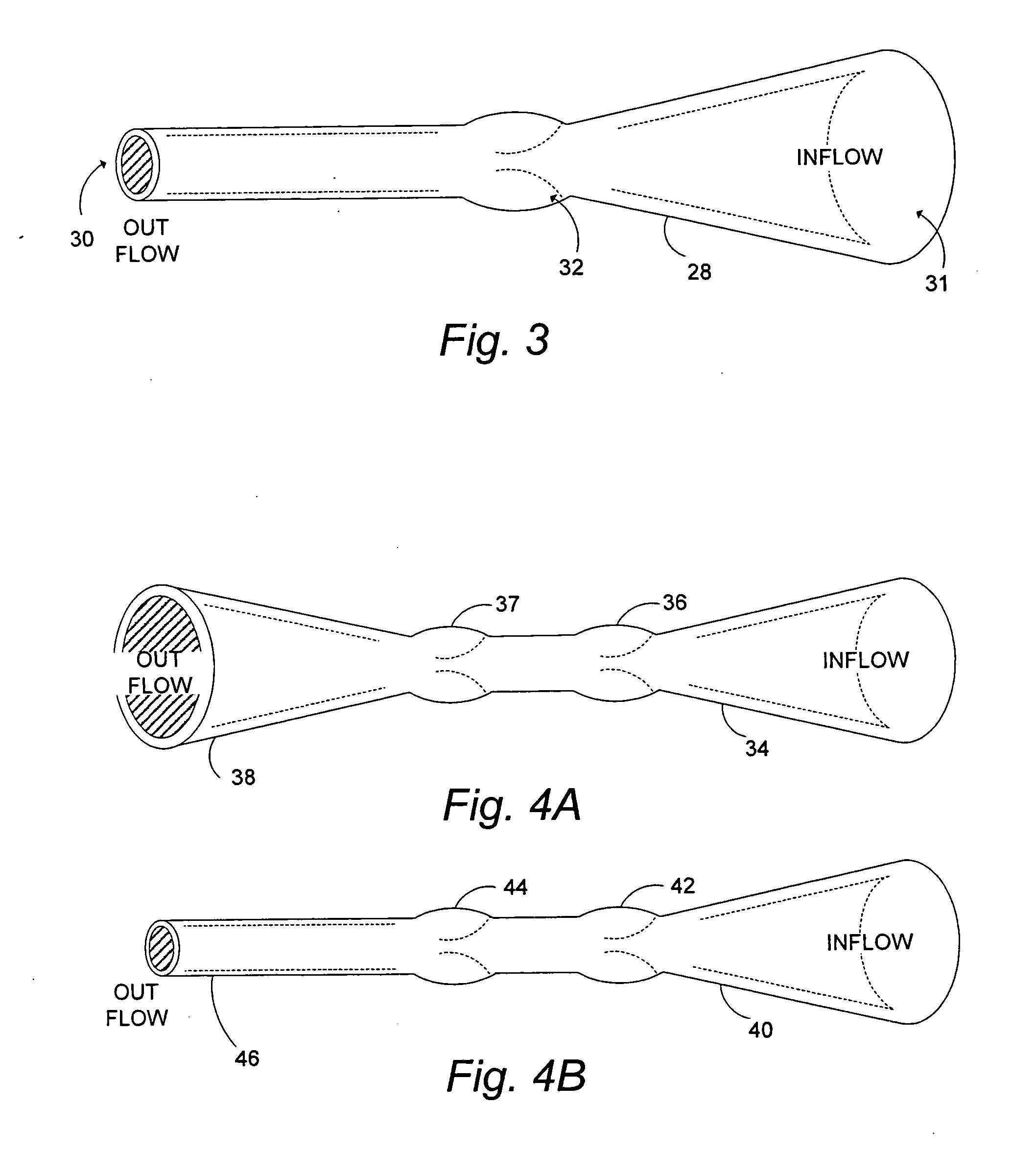

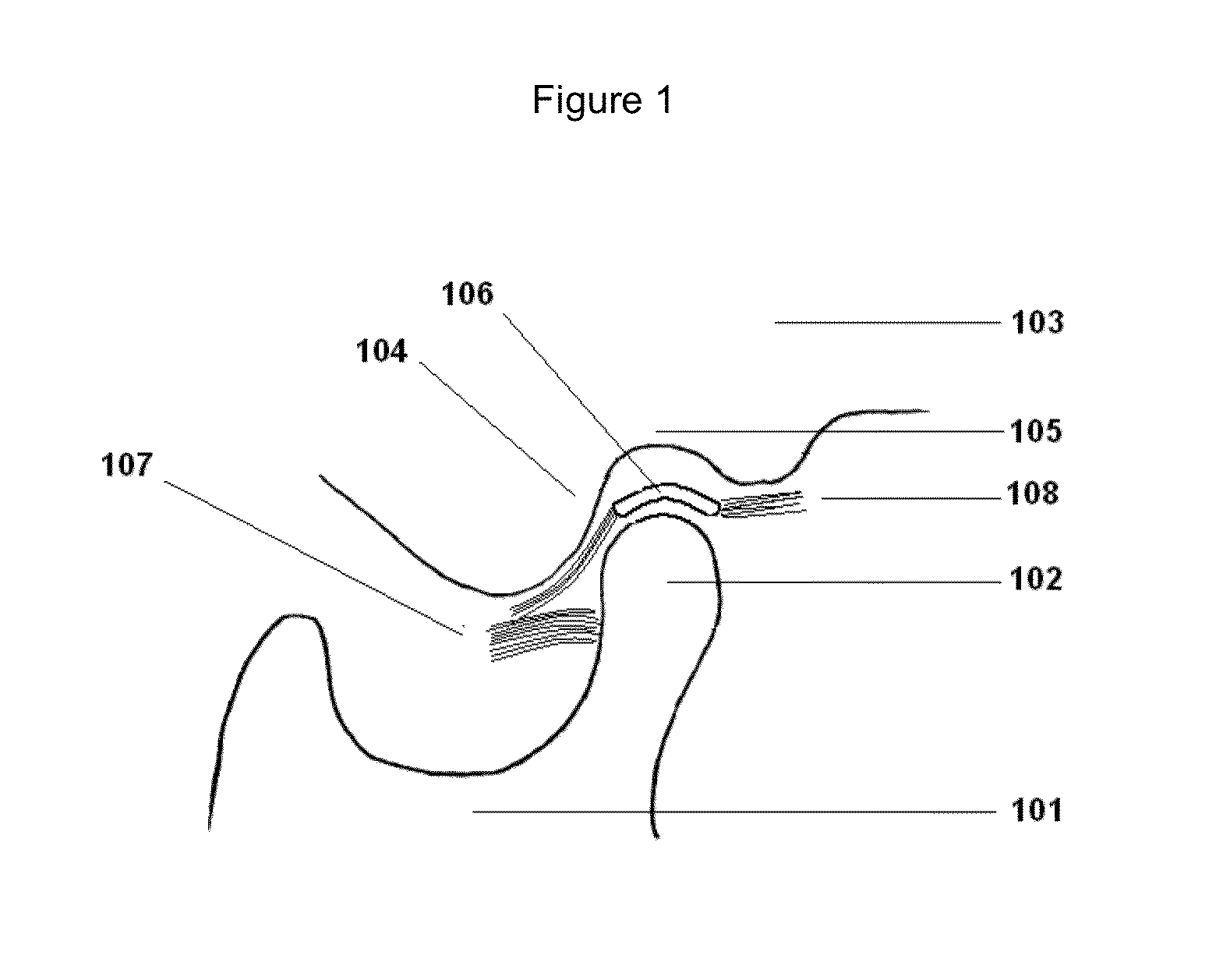

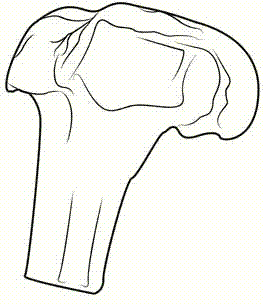

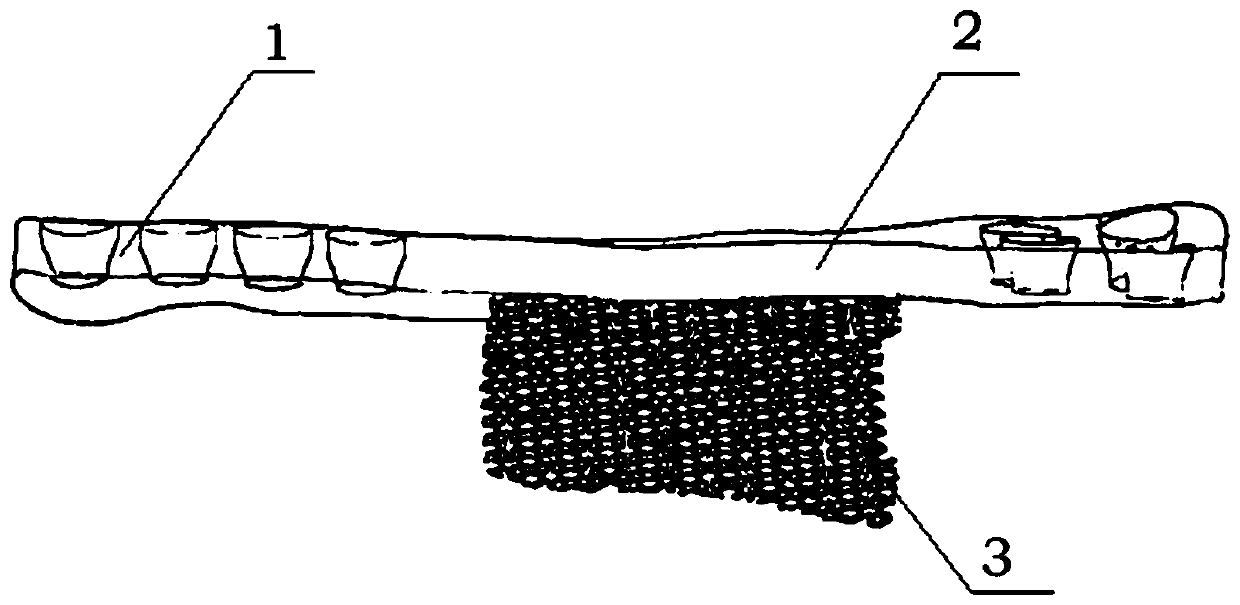

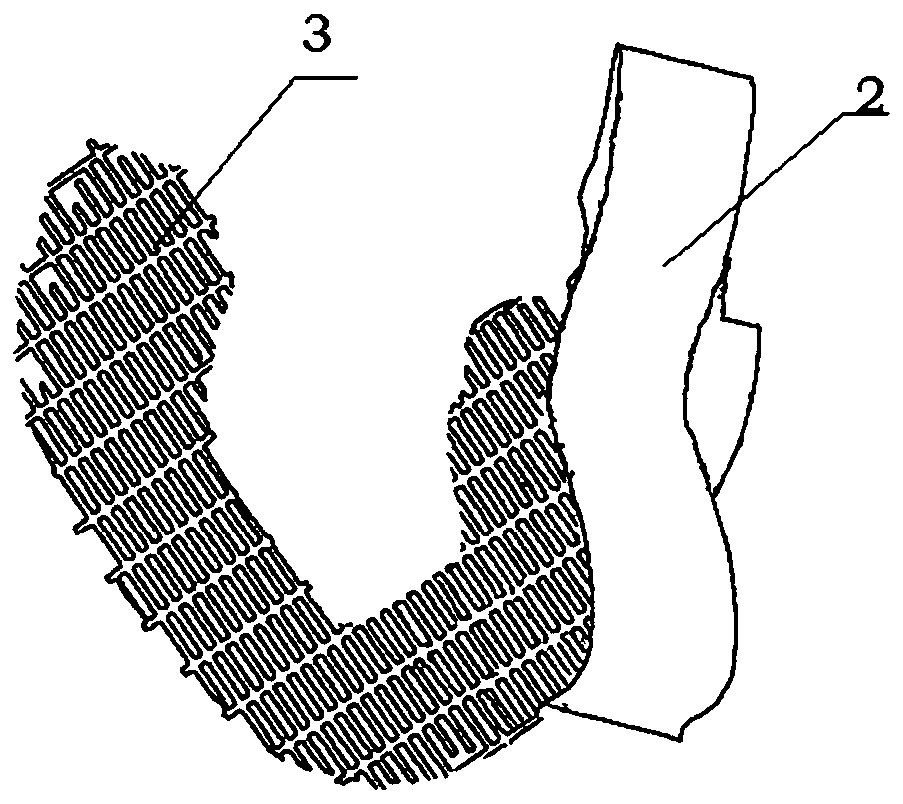

Venous valve prosthesis and method of fabrication

The invention provides venous valve prostheses design and method of fabrication useful for replacement of venous valves in the treatment of patients. The venous valve prostheses of the invention comprise at least one integrally formed valve with a proximal converging nozzle and / or a distal diverging nozzle to maintain a proper blood flow rate through the valve.

Owner:JEFFREY M GROSS

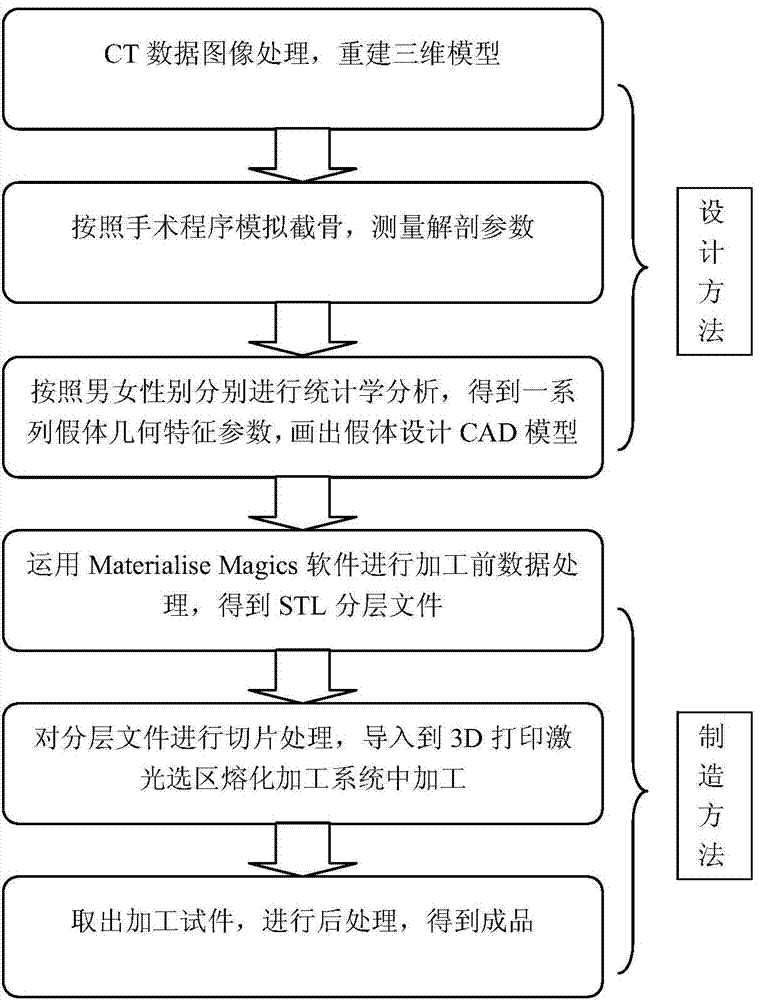

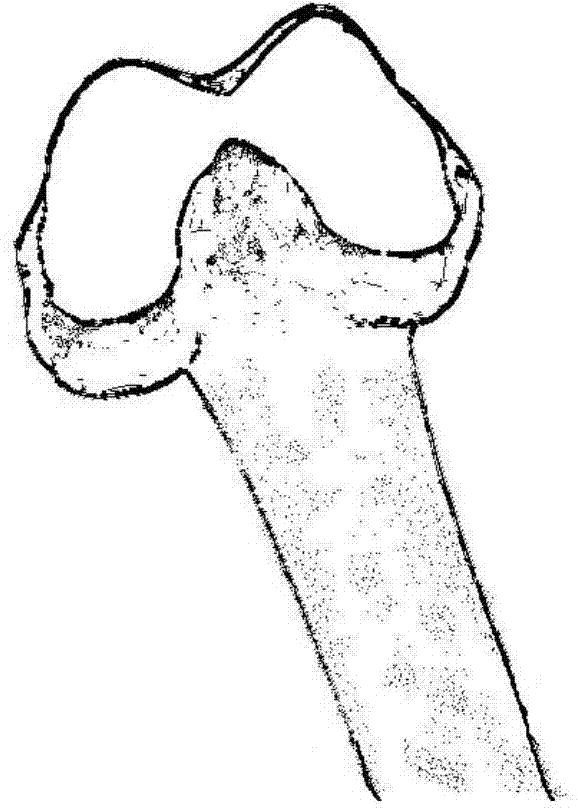

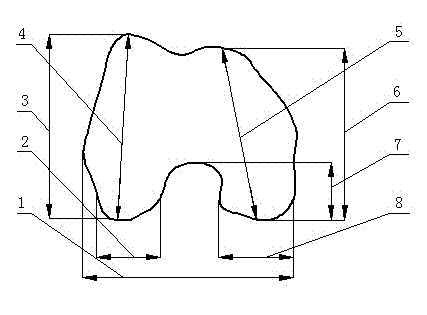

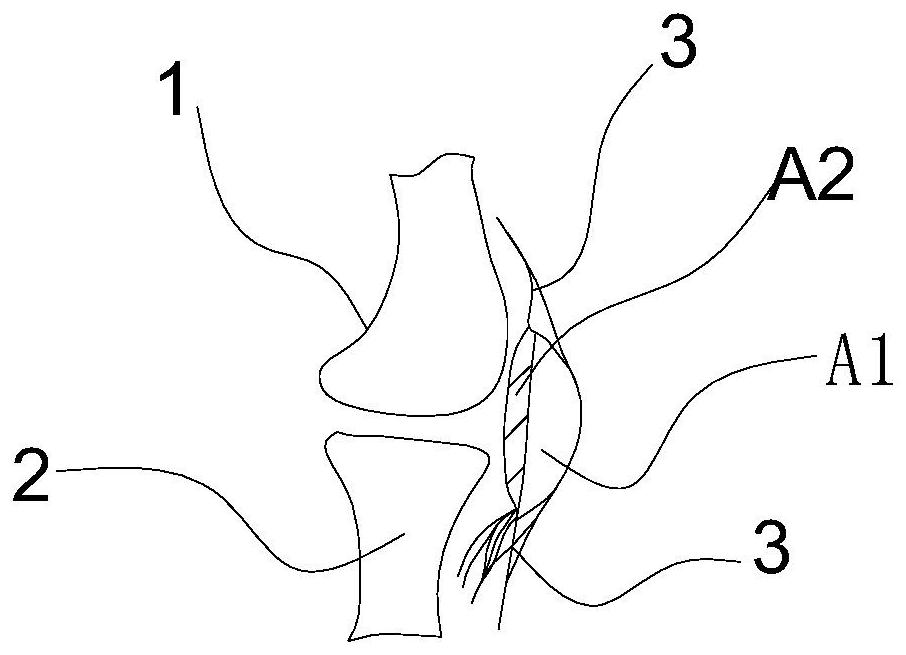

Designing method and manufacturing method of knee joint femoral prosthesis used for total knee arthroplasty

ActiveCN103584932AGood compatibilityShort processing cycleJoint implantsKnee jointsTotal hip arthroplastyDICOM

The invention discloses a designing method and a manufacturing method of a knee joint femoral prosthesis used for total knee arthroplasty. The designing method includes the following steps: S11, on the basis of CT (computed tomography) data of a normal Chinese person and in a medical image DICOM format, applying medical image software Mimics to build a three-dimensional digital model of a femur, and outputting a PLY-format file; S12, leading the digitalized femoral model PLY file in Geomagic Studio software, establishing a three-dimensional coordinate system, and utilizing a measuring tool to collect geometric parameters related to prosthesis designing; S13, performing statistical analysis on collected data by utilizing statistical software, and utilizing three-dimensional drawing software to draw a solid entity of the knee joint femoral prosthesis. The designing method and the manufacturing method have the advantages that a series of femoral prostheses different in type exist for men and women respectively, different knee joint femoral skeleton anatomical morphological features of men and women in China can be met, and matching degree of prostheses and knee joints is increased.

Owner:BEIJING NATON TECH GRP CO LTD +1

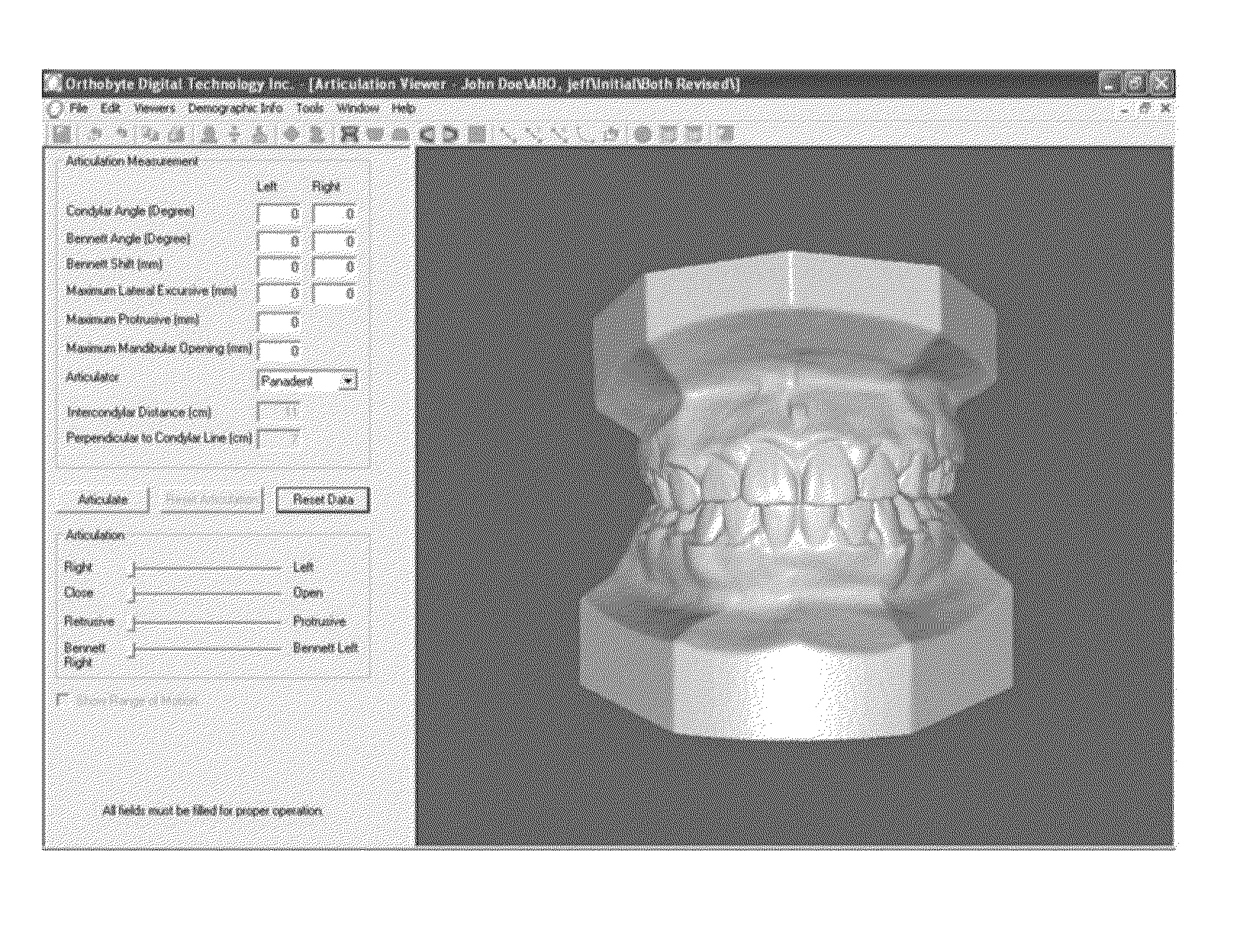

Virtual articulator

InactiveUS20130204600A1Medical simulationAnalogue computers for chemical processesProsthodonticsRange of motion

The invention is a three dimensional virtual articulator used for but not limited to diagnosing and treatment planning for dental and medical specialties, including orthodontics, prosthodontics, endodontics, periodontics, orthognathic surgery, implant positioning, crown and bridge and prosthesis design.The operator enters patient-specific anatomical measurements for condylar angles, Bennett angle and shift, lateral excursive and protrusive movements, and maximum mandibular opening, and a selection of preset or customizable intercondylar distances to simulate the unique mandibular range of motion.The patient-specific measurements create a customized complex polygon that illustrates the maximum limits of the mandibular range of motion. The operator is able to use onscreen controls to move the virtual mandible in relation to the virtual maxilla within the parameters described by the patient-specific measurements input by the operator.The first point of contact as well as surface interferences can be marked on the dynamic surfaces of the two virtual arches.

Owner:MEHRA TARUN

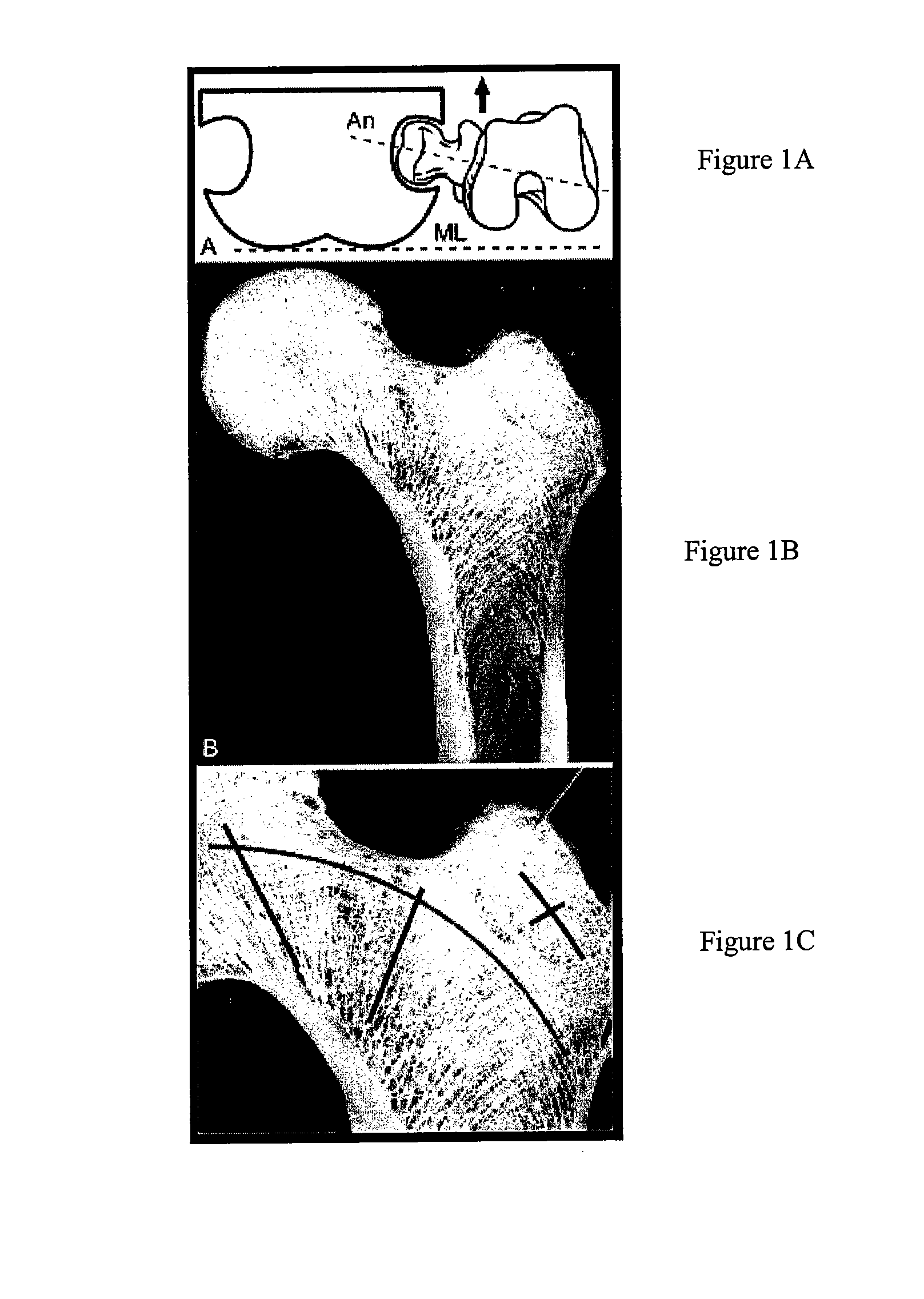

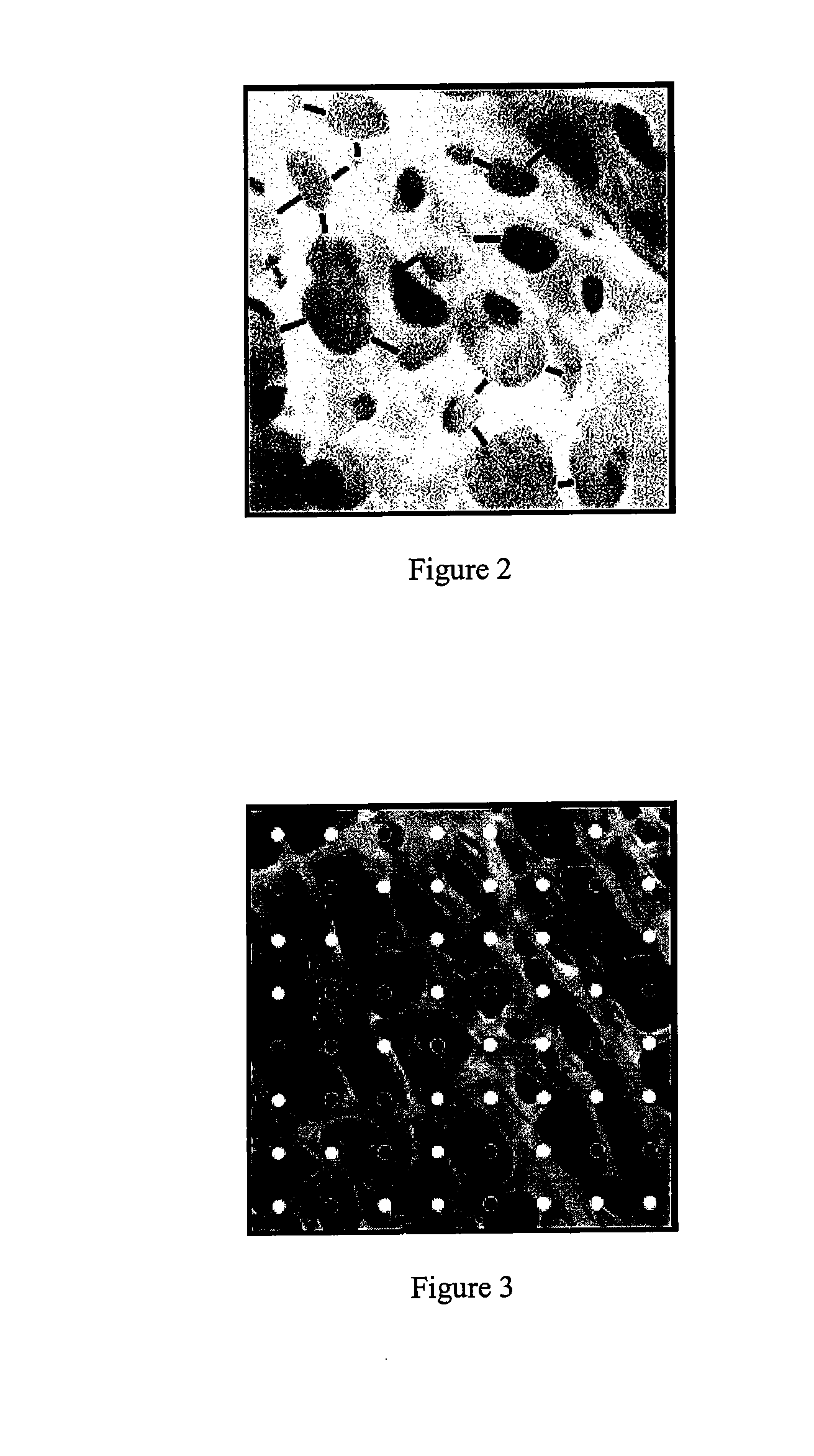

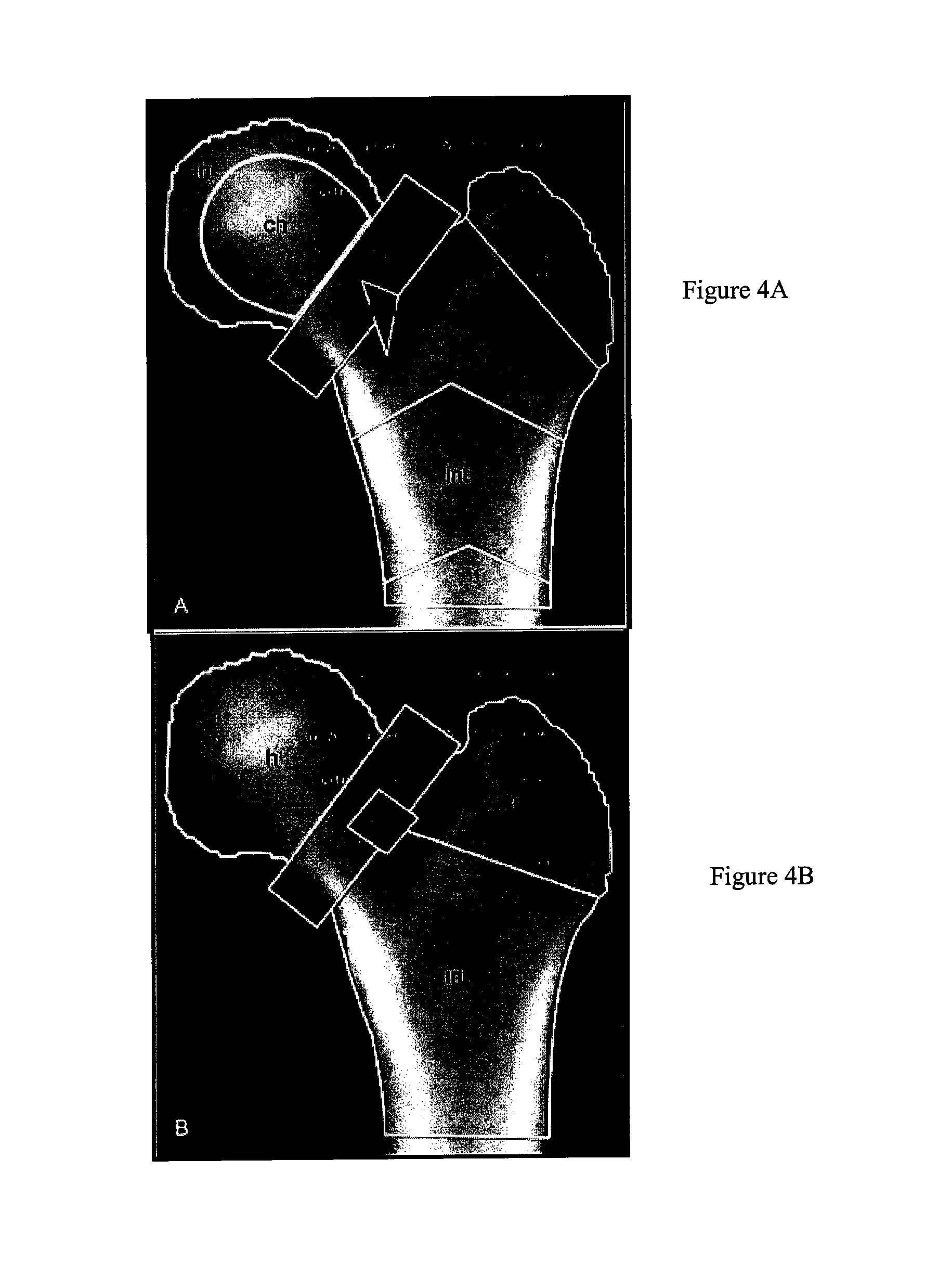

Templates for assessing bone quality and methods of use thereof

InactiveUS20080119719A1Realistic and accurate depictionConvenient medical treatmentImage enhancementImage analysisFractographyVolumetric Mass Density

The present invention relates to the preparation and use of novel bone templates that can be prepared using a comprehensive approach to observing microstructural features of bone, including trabecular thickness and trabecular density. These features are assessed in regions of interest in a bone (e.g., proximal femur, distal femur, wrist, spine, etc.) as observed using digital radiographic techniques or clinical imaging, such as Dual Energy X-ray Absorptiometry (DEXA) and computed tomography (CT) scanners. The microstructural features are presented in the form of data based on scanning results and are also assessed and / or organized in terms of age, gender, race, pathology, clinical history, and other patient population parameters. The template can be used to assess bone quality, predict the likelihood of bone fracture, and evaluate prosthesis design and placement, based on an image of a corresponding subject bone, e.g. the bone of a patient.

Owner:RGT UNIV OF CALIFORNIA

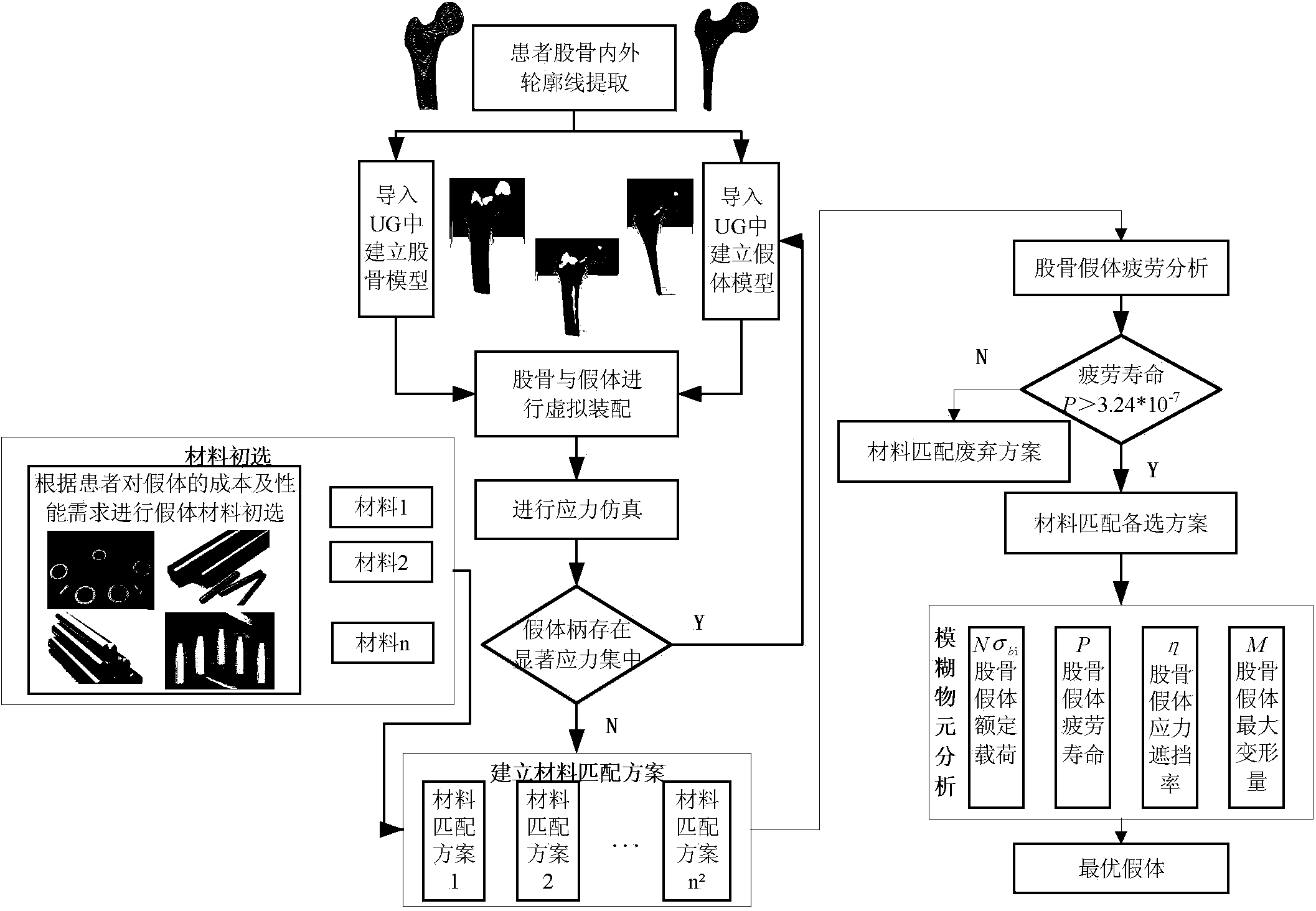

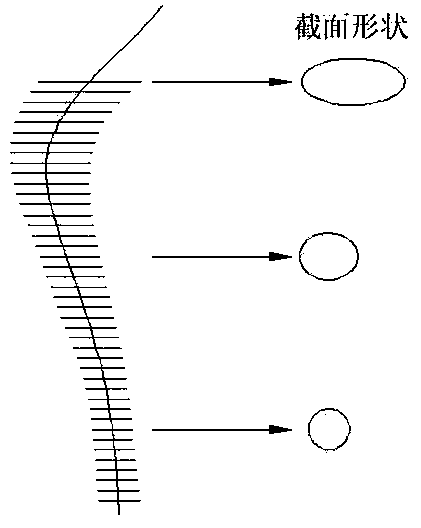

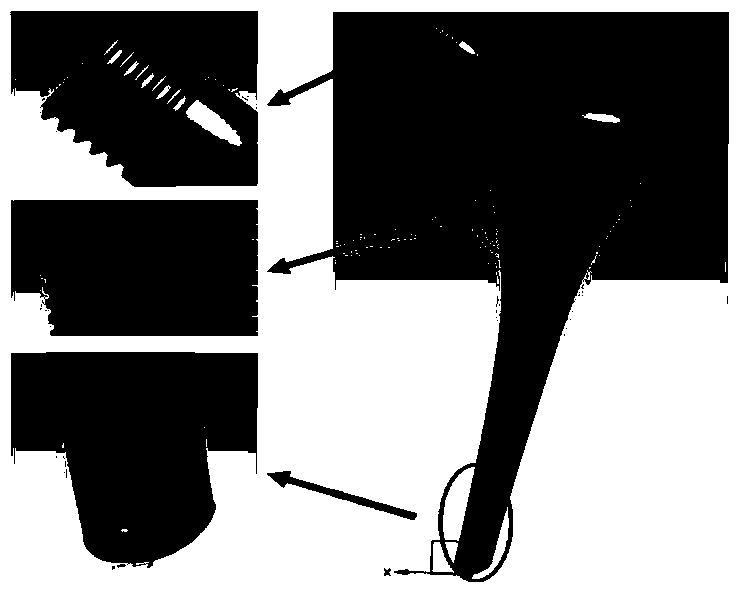

Method for optimally selecting thighbone prostheses based on material performance multi-objective optimization

InactiveCN103530466AAchieve optimizationDesign fusionSpecial data processing applicationsElement modelElement analysis

The invention discloses a method for optimally selecting thighbone prostheses based on material performance multi-objective optimization, and relates to the field of thighbone prosthesis design. The method comprises the step of utilizing the finite element analysis method for conducting the multi-objective optimization on the thighbone prostheses so as to achieve optimal selection of individualized thighbone prosthesis. The method is characterized by comprising the steps of extracting a thighbone internal contour line and a thighbone external contour line, structurally designing a thighbone prosthesis handle, structurally designing a ball head, assembling a thighbone model and a prosthesis model, selecting thighbone prosthesis materials, establishing a finite element model, setting determined material parameters, constructing a material matching mode and loads, and optimizing evaluation indexes and multiple objectives. The material matching scheme of the ball head and the prosthesis handle is the optimal scheme obtained on the premise that the thighbone prosthesis bearing capacity, the thighbone prosthesis service life, the thighbone prosthesis stress shielding and thighbone prosthesis deformation are optimized under the individual thighbone mechanical environment, the problem of optimally selecting the artificial prostheses is solved by initially applying the fuzzy matter-element theory, and due to the introduction of the method, the multi-objective optimization design of the thighbone prostheses is achieved.

Owner:HARBIN UNIV OF SCI & TECH

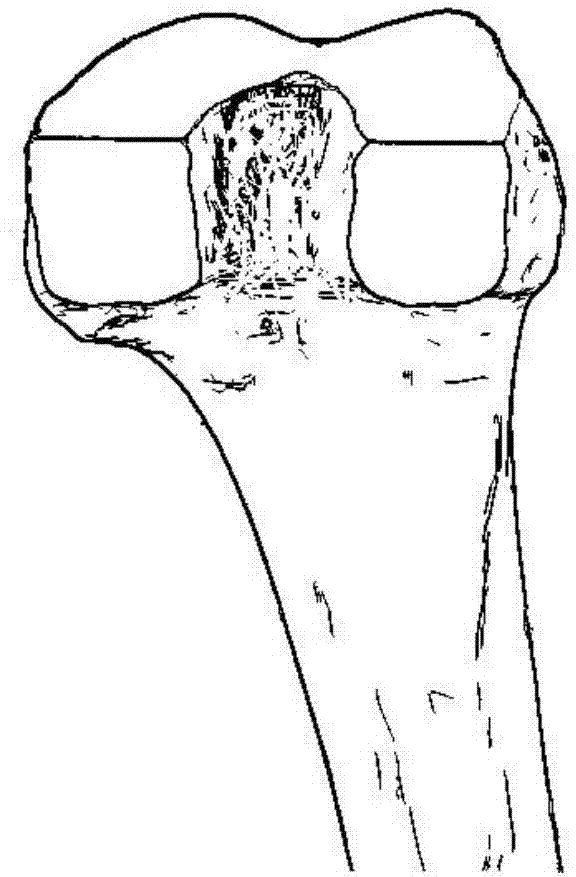

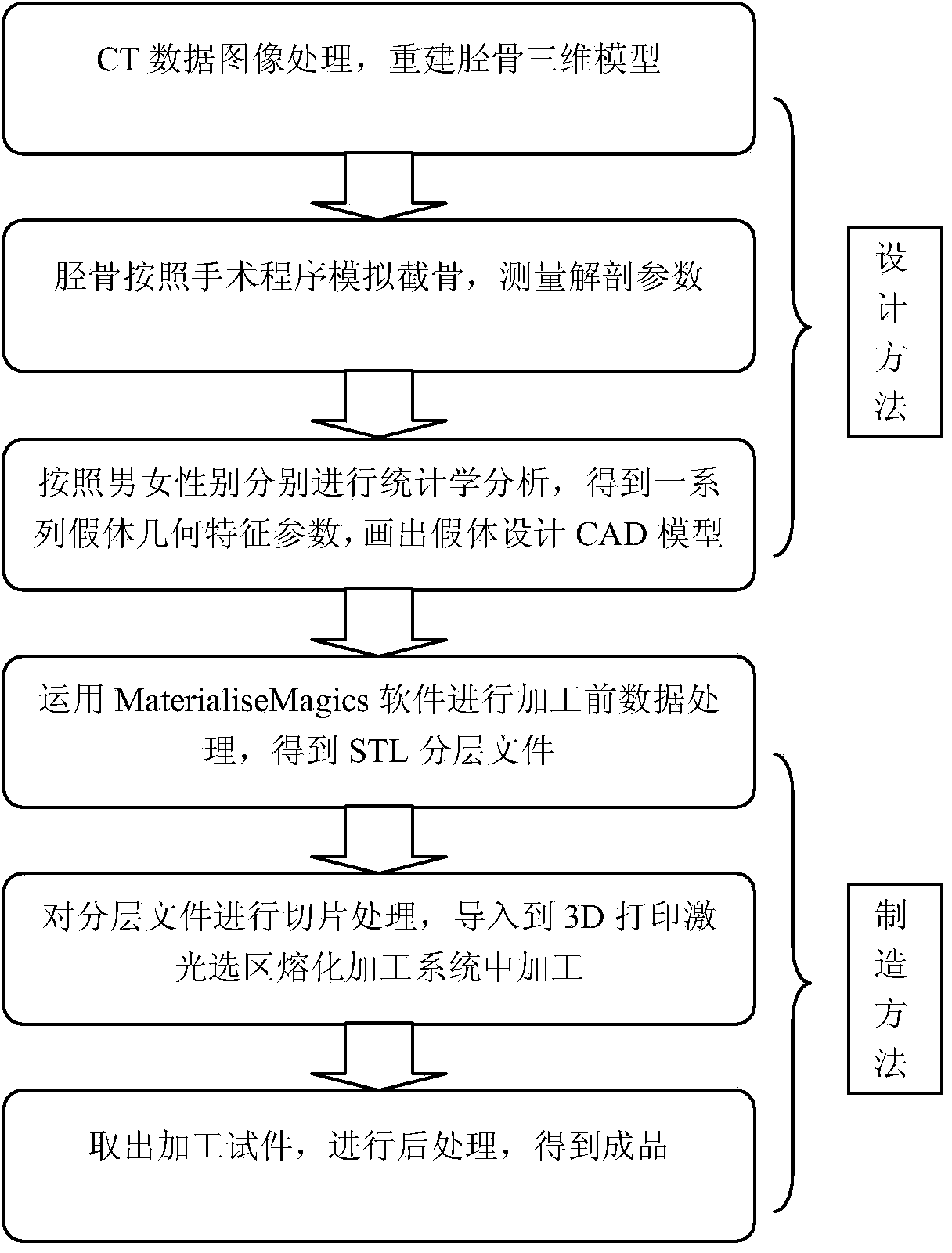

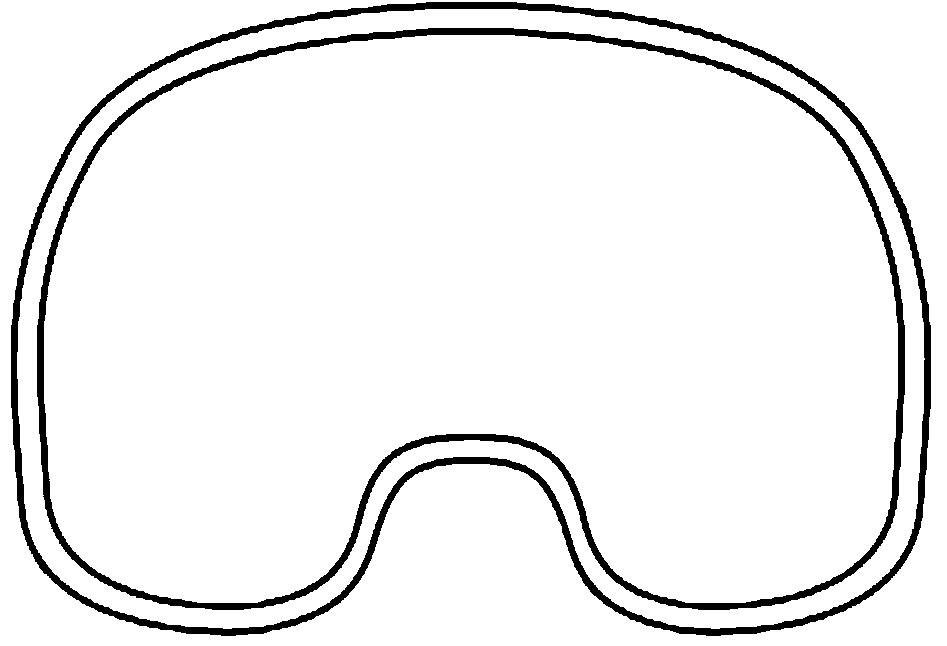

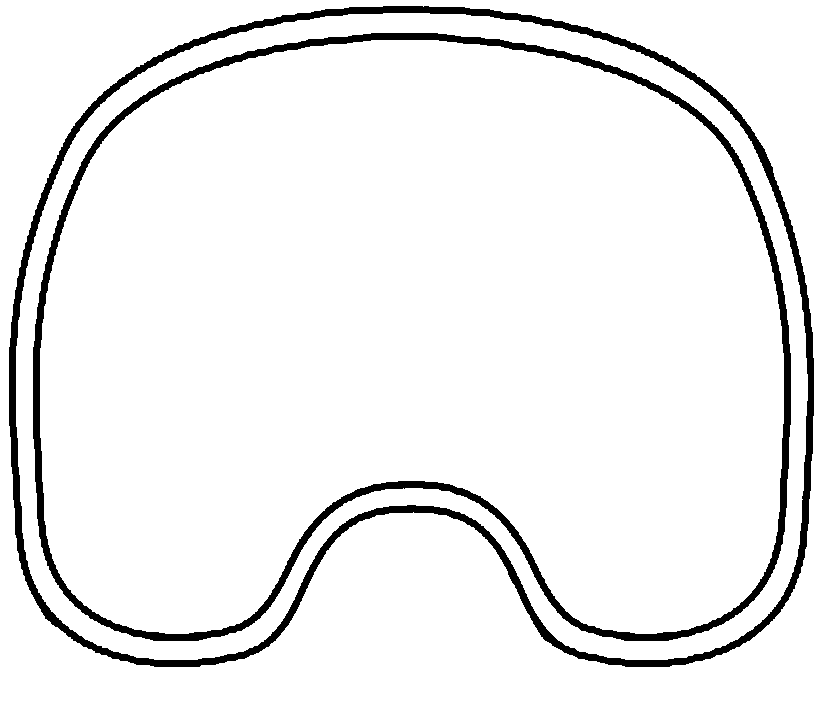

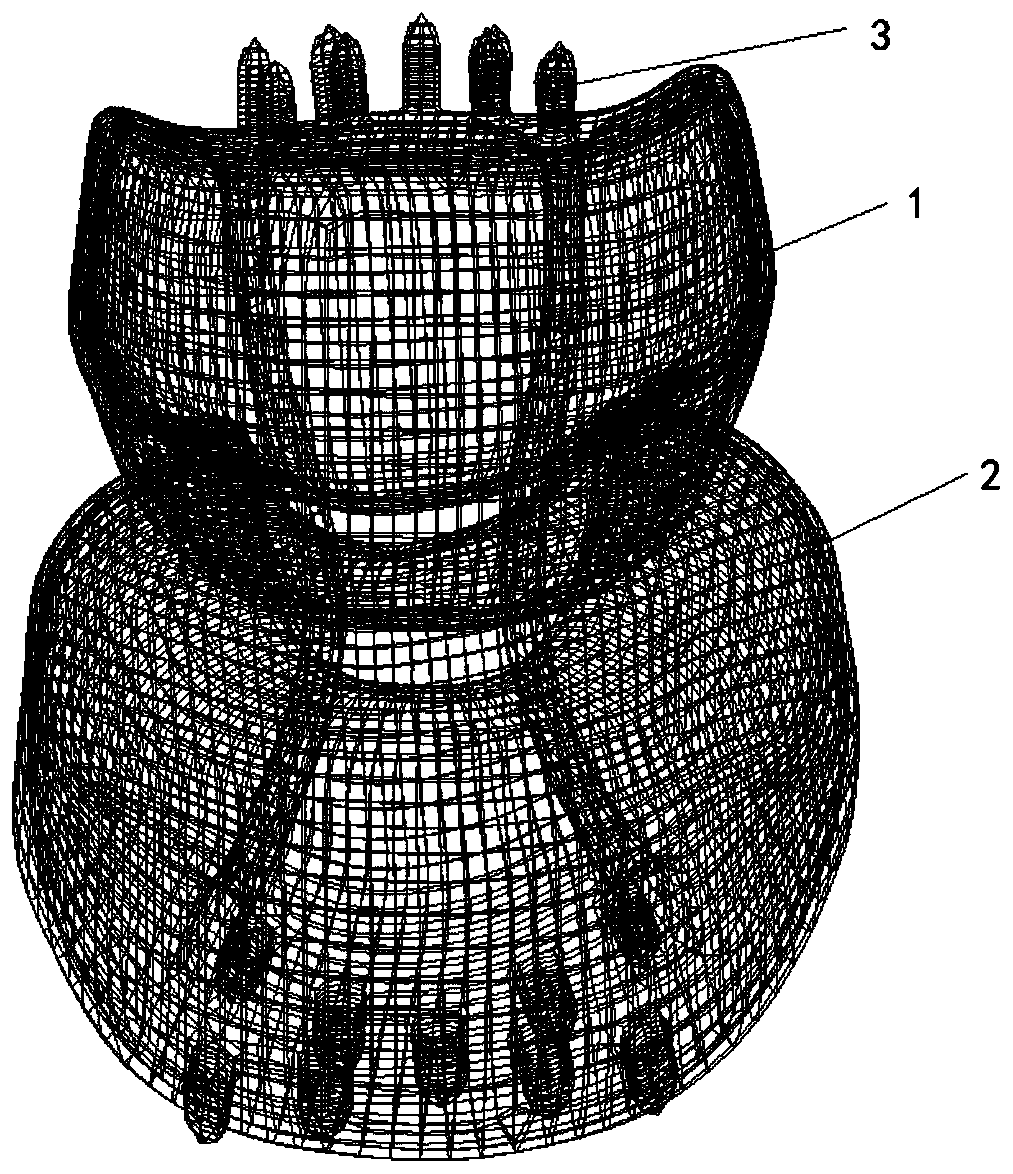

Digital design and manufacturing method for knee joint tibia prosthesis

InactiveCN103860295AIncrease coverageImprove yieldJoint implantsKnee jointsTibiaMedical imaging data

The invention relates to a digital design and manufacturing method for a knee joint tibia prosthesis. The method comprises the steps of (1) establishing a knee joint tibia three-dimensional digital model according to medical image data based on the knee joint tibia of healthy people; (2), performing digital simulation of tibia rear end osteotomy according to a knee joint arthroplasty surgery scheme and measuring the design-related geometric parameter of the tibia prosthesis; (3), obtaining the geometric shape parameters of the tibia prosthesises of different genders and models according to the statistical analysis, and drawing the tibia prosthesis design model; (4) manufacturing the knee joint tibia prosthesis according to the tibia prosthesis design model through a 3D (three-dimensional) printing technology. According to the digital design and manufacturing method for the knee joint tibia prosthesis, the tibia prosthesises of different genders and models can be obtained, the prosthesises can be matched with the anatomic form features of different knee joint tibia skeletons of male and female in China, and the coverage rate between the prosthesises and the osteotomy section of the knee joint tibia and the good rate of surgeries are improved.

Owner:PEKING UNIV THIRD HOSPITAL +1

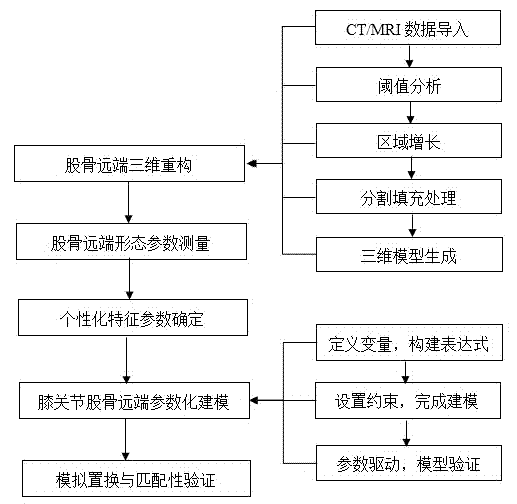

System for designing individual artificial knee joint prosthesis based on parameter driving

ActiveCN104739548AImprove the secondary application rateImprove quality and efficiencyJoint implantsKnee jointsBone morphologyMedical product

The invention relates to a system for designing an individual artificial knee joint prosthesis based on parameter driving, in particular to individual parameter driving of a femoral prosthesis model and belongs to the field of design of medical products. The system for designing the individual artificial knee joint prosthesis based on parameter driving is based on the interactive visual medical image processing and computerized design technique. According to the system for designing the individual artificial knee joint prosthesis based on parameter driving, a skeleton model is re-constructed by means of an interactive medical image processing module, and bone morphology parameter values are obtained through measurement; individual parameters of prosthesis design are analyzed through a femoral prosthesis individual parameter analyzing module; parametric modeling of prosthesis individual parameters is completed by establishing a parameter expression, establishing a parameter preliminary sketch, adding constraint, scanning and the like; the femoral prosthesis parameters are adjusted, and matching verification of the prosthesis design is conducted. According to the system, individual modeling of the prosthesis can be achieved by automatically modifying variables according to the actual physiological characteristic parameter of a patient, both design quality and design efficiency can be improved, products can be designed and manufactured according to the shapes and sizes of bones of different patients, and both production requirement and practical clinic requirements are met.

Owner:SHANGHAI XINJIAN MEDICAL TECH

Method for preparing individually-customized pelvic tumor prosthesis

ActiveCN102349843ARealization of individual customizationFlexible designProsthesisResonanceTumour therapy

The invention relates to a method for preparing individually-customized pelvic tumor prosthesis. The method comprises the following steps of: reconstructing three-dimensional models of pelvises and tumors according to two-dimensional images of captive tests (CT), magnatic resonance imaging (MRI) and the like of patients before operations, demarcating a tumor excision boundary according to a tumor therapeutic principle, and determining a plane and an angle of pelvic osteotomy; and reconstructing the three-dimensional models of amputated pelvic defect parts by comparing with normal pelvises, designing and producing individually-customized prosthesis, and performing surface modification on a contacting section of a prosthesis material and bones to fulfill the aim of combining the prosthesis material and the bones stably. The pelvic tumor prosthesis designed by the method can be customized individually aiming at the tumor excision range of different patients to retain bone mass as far as possible while the tumors are excised completely, and can be matched with the original pelvic excision parts accurately to realize accurate pelvic reconstruction operations; bone integration is formed between the prosthesis and the bones to ensure the long-term stability of the prosthesis; and hip joints of the prosthesis are designed by super-radium acetabuli, so the prosthesis is stable and has a motion function.

Owner:维度(西安)生物医疗科技有限公司

Personalized prosthesis and making method and using method thereof

InactiveCN106175998AImprove surgical precisionImprove surgical safetyAdditive manufacturing apparatusSpinal implantsPersonalizationProsthesis

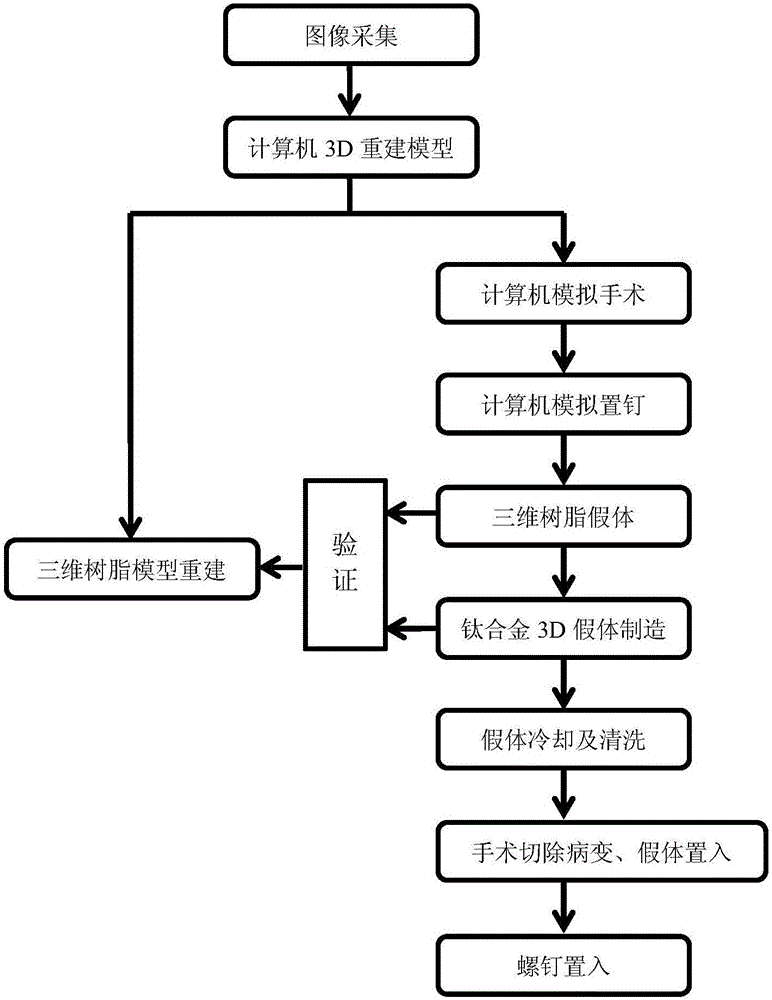

The invention discloses a personalized prosthesis and a making method and using method thereof. The making method comprises the steps of image acquisition, three-dimensional digital modeling, resin model establishment, computerized surgery simulation, model revalidation, internal fixation scheme making, prosthesis size formulation, personalized prosthesis parameter determination, prosthesis 3D printing and prosthesis cooling and cleaning. The personalized prosthesis obtained through 3D printing is especially suitable for spine, prosthesis design and simulation of reestablishment of a spine structure after excision can be conducted with a computer before operation, specific schemes can be made according to requirements of patients, and surgery precision and safety are improved.

Owner:BEIJING ZHONGNUO HENGKANG BIOTECH

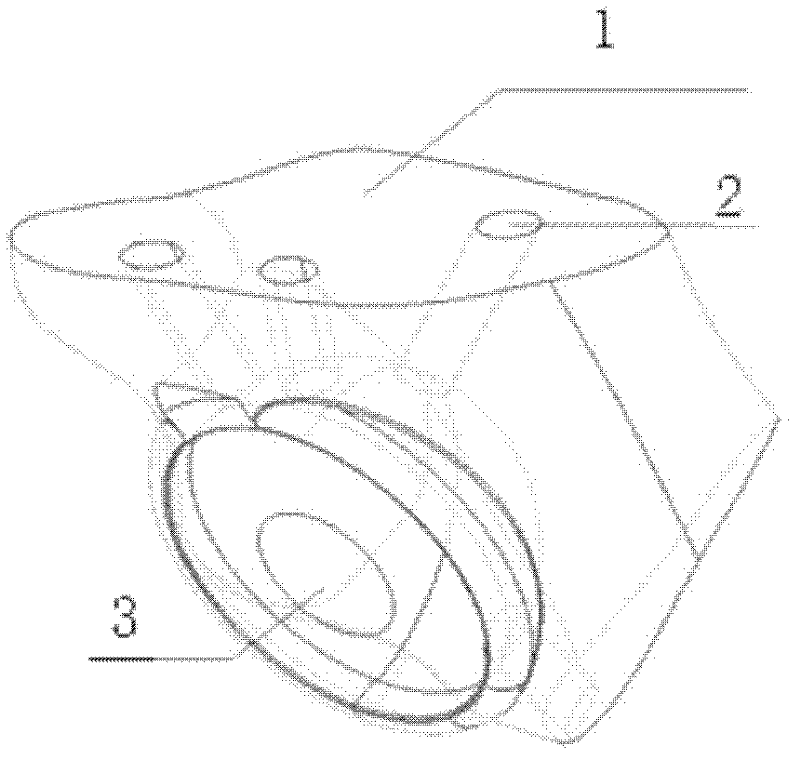

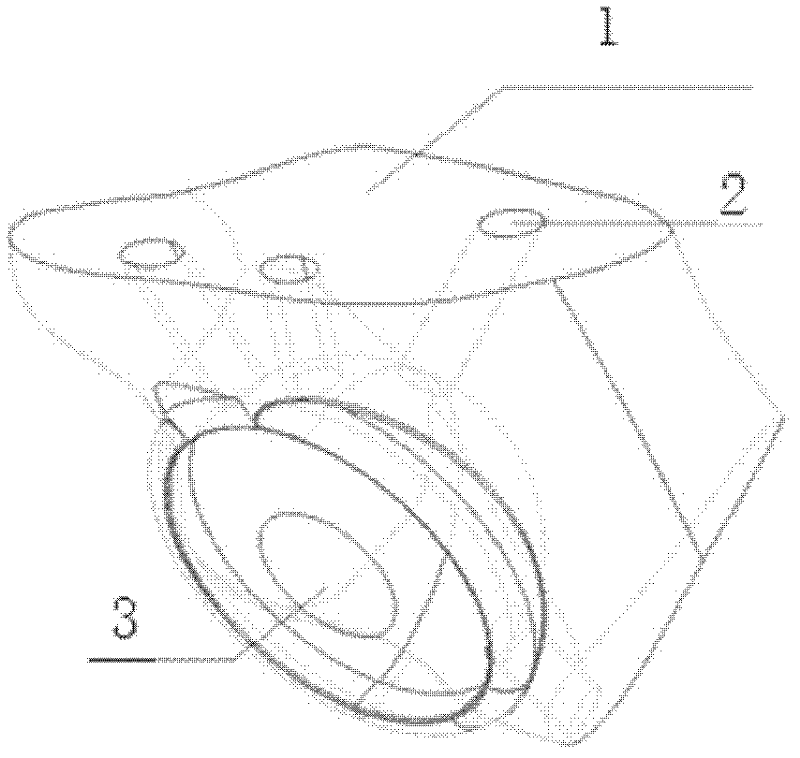

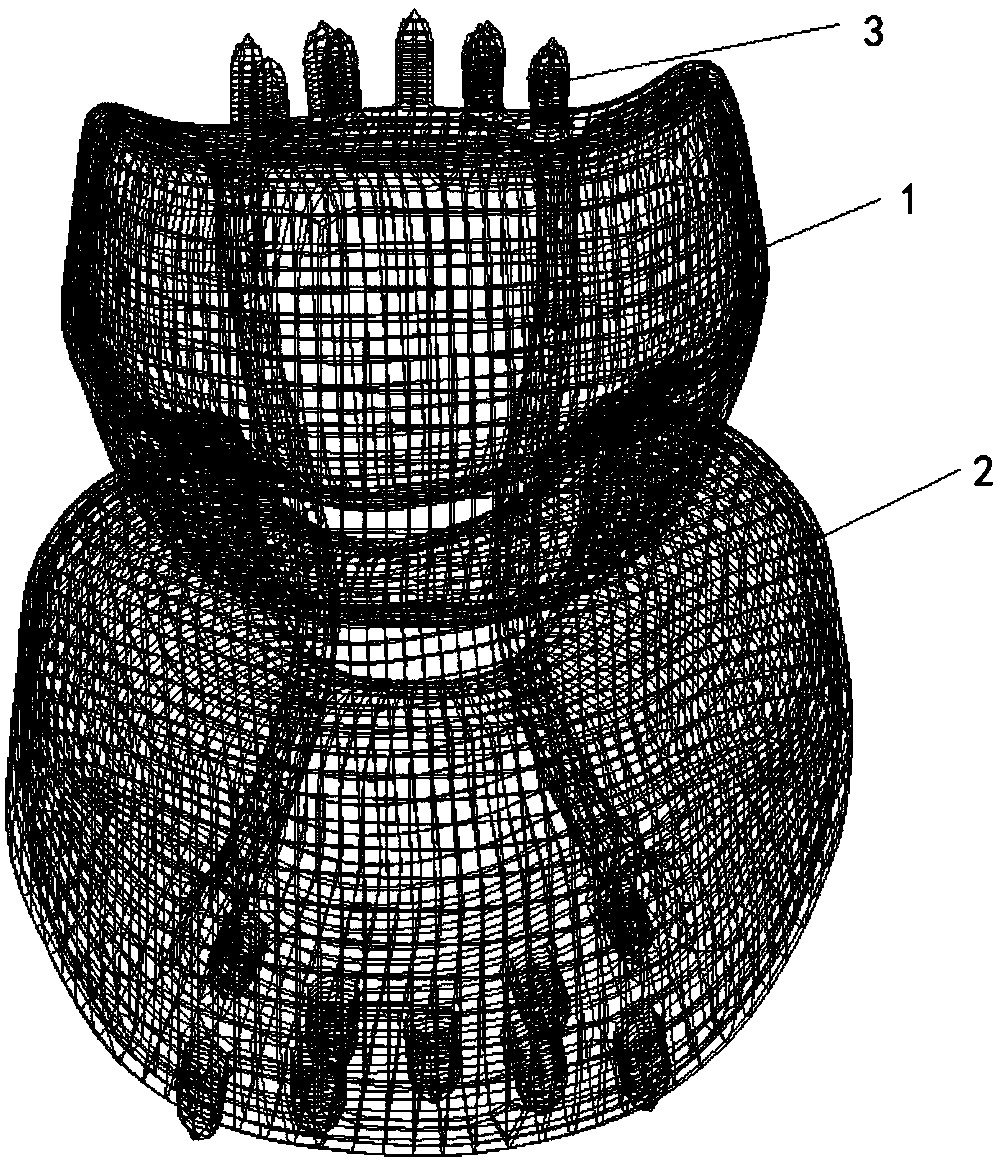

Design method of personalized condylar prosthesis with topological optimized fixing unit and porous condylar head unit, and personalized condylar prosthesis

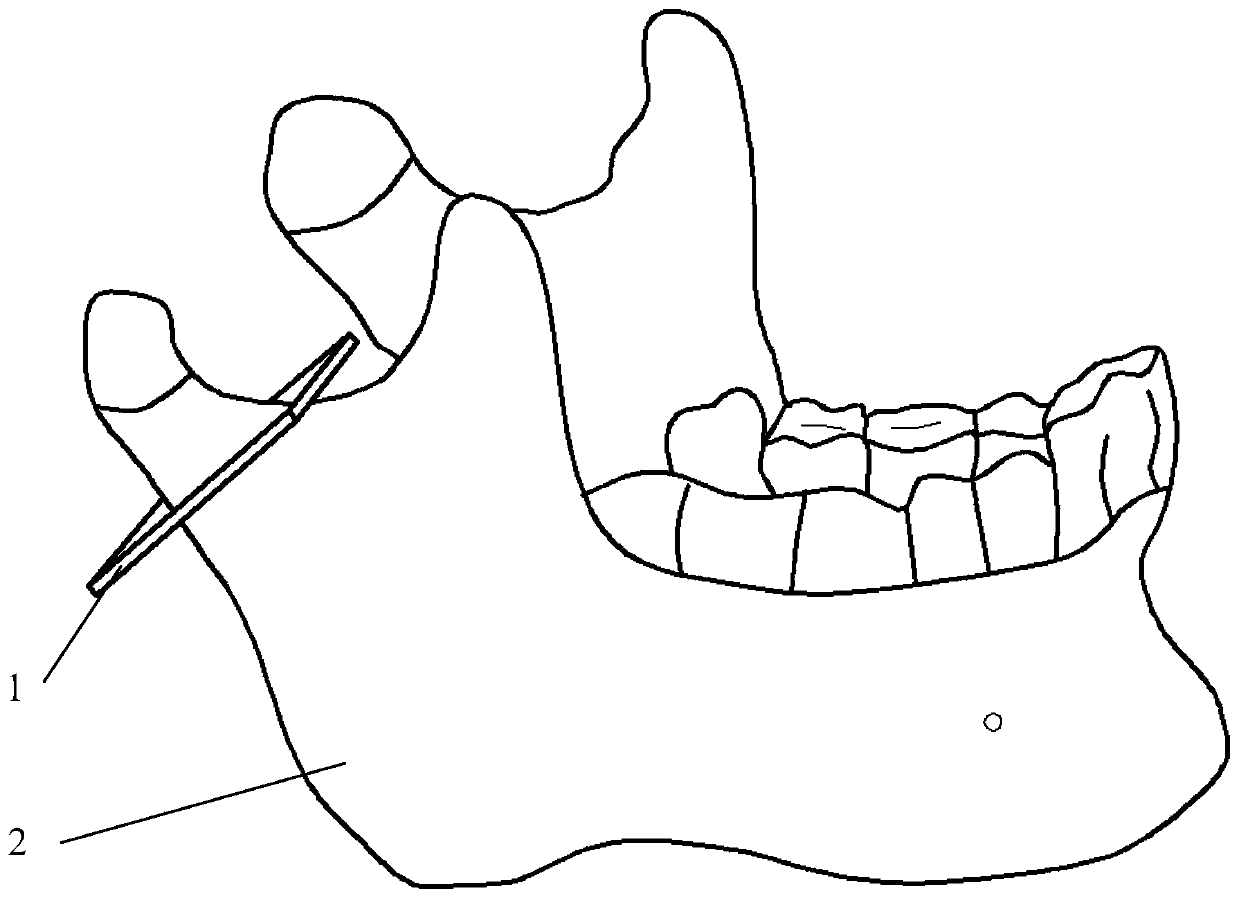

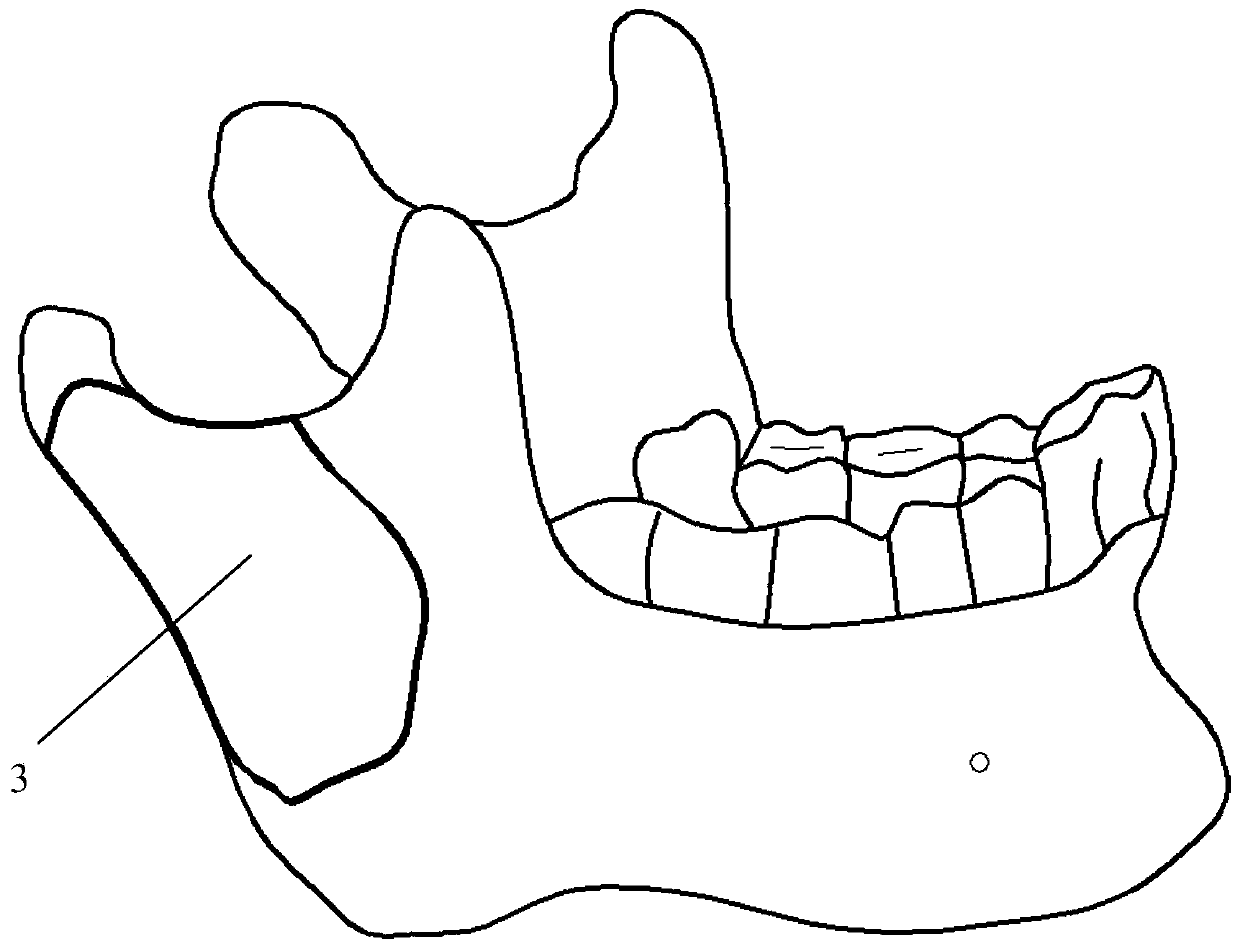

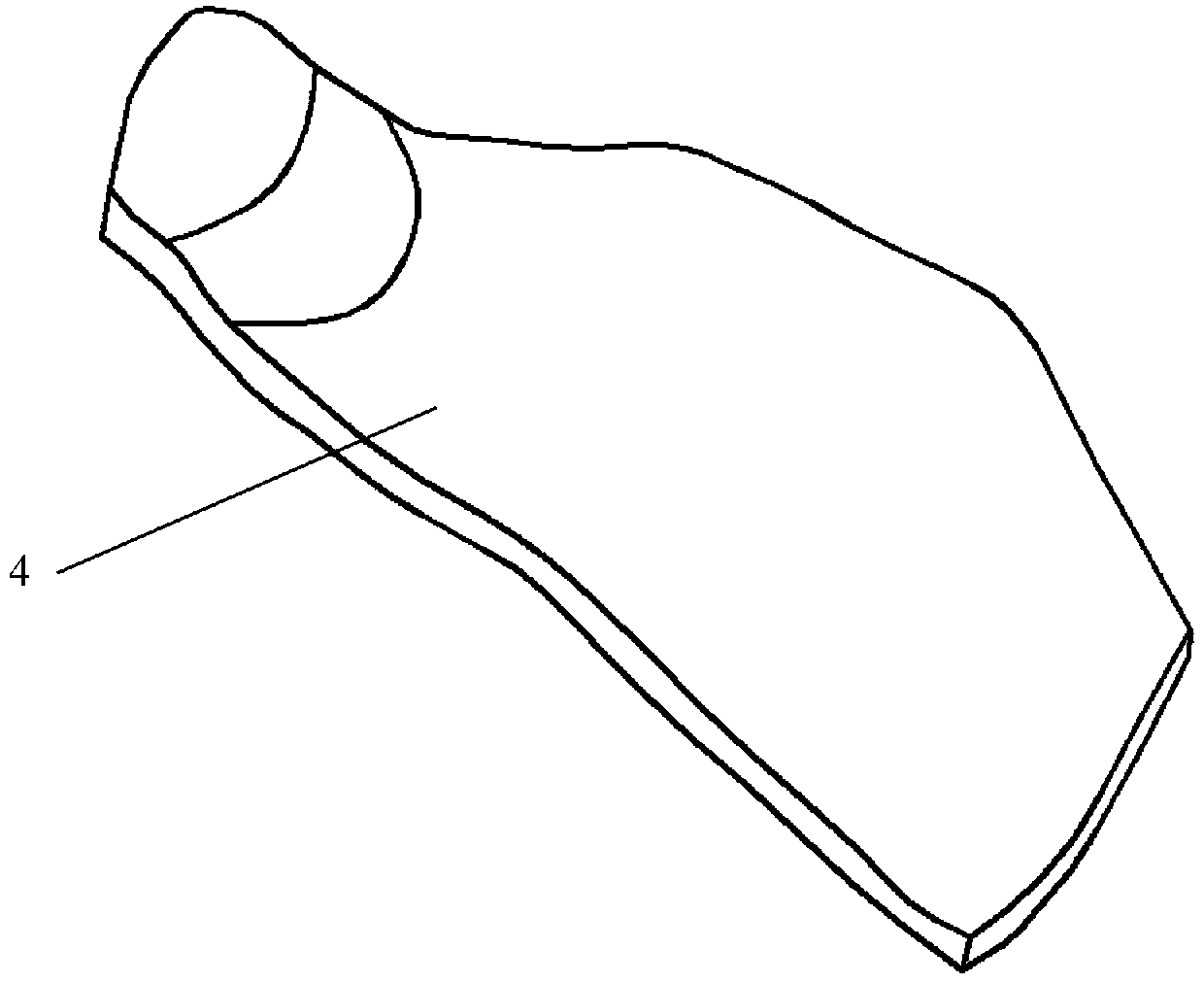

The invention relates to a design method of a personalized condylar prosthesis with a topological optimized fixing unit and a porous condylar head unit. The method comprises the following steps: 1) reconstructing a condylar prosthesis and constructing a mandible biomechanical model; 2) performing topological optimization design on a fixing unit based on biomechanics; 3) designing the porous structure of the condylar head; 4) carrying out 3D printing on the personalized condylar prosthesis; and 5) carrying out post-treatment on the printed personalized condylar prosthesis to obtain the personalized condylar prosthesis which is applied to clinic and has the topological optimized fixing unit and the porous condylar head. The invention provides the design method of the personalized condylar prosthesis with the topological optimized fixing unit and the porous condylar head unit, and the personalized condylar prosthesis. The method effectively reduces the average maximum stress of the prosthesis, so that the prosthesis has better stability and is not easy to fall off.

Owner:ZHEJIANG UNIV OF TECH

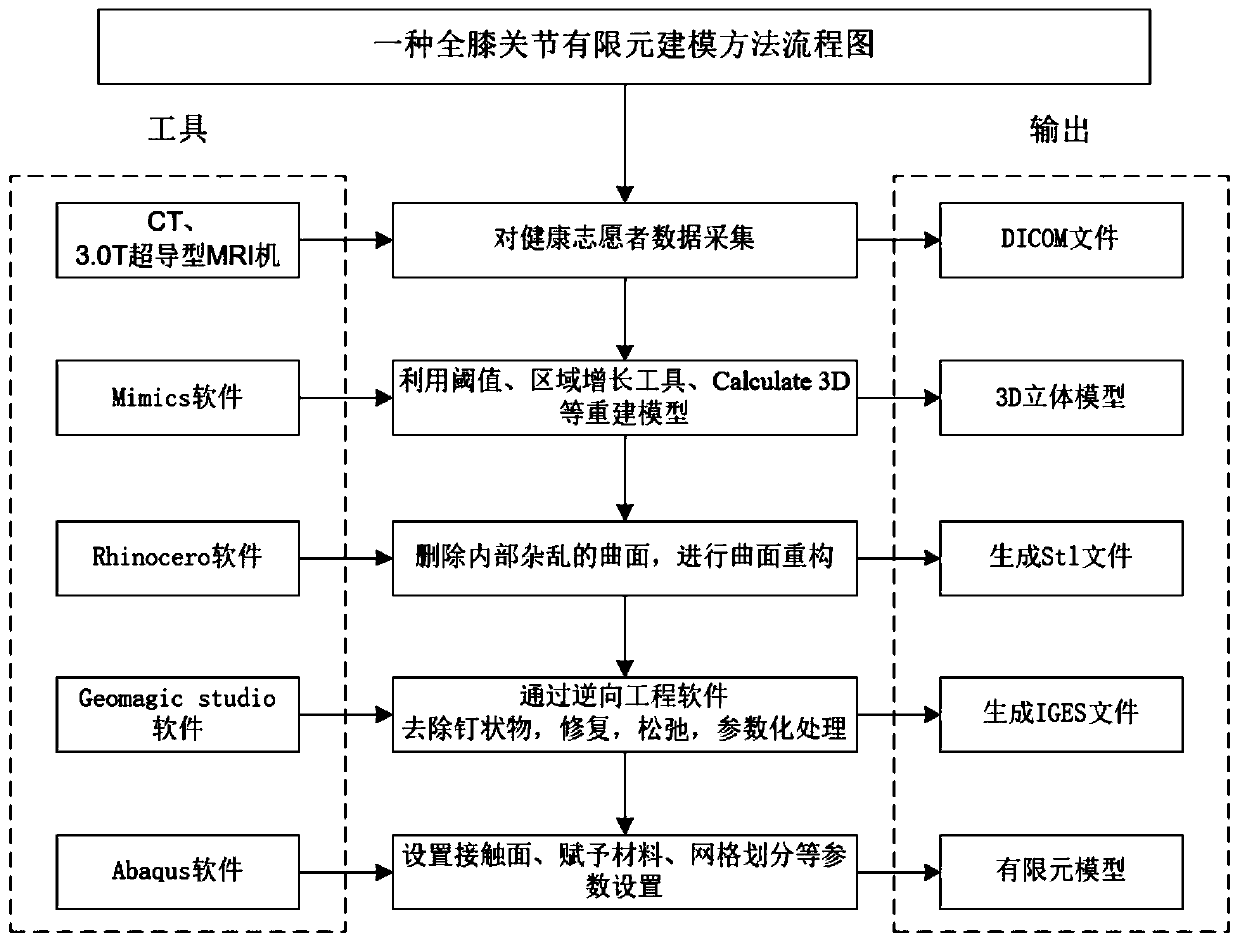

Total knee joint finite element modeling method

PendingCN110443005AQuick deleteModify control pointSpecial data processing applications3D modellingElement modelCoronal plane

The invention provides a total knee joint finite element modeling method, and belongs to the technical field of joint modeling. The method comprises the steps of collecting knee joint data; opening the data file and determining images of a coronal plane, a cross section and a sagittal plane; dividing the required bone tissue on the sagittal plane or the coronal plane; obtaining a three-dimensionalmodel of the bone tissue; obtaining a three-dimensional model of the soft tissue; registering the three-dimensional model of the bone tissue and the three-dimensional model of the soft tissue to obtain a total knee joint model; deleting messy structural surfaces in the total knee joint model; simplifying triangular patches, removing nails, repairing, relaxing, parameterizing curved surfaces and accurately curved surfaces of the knee joints, and finally storing the curved surfaces as IGS files to complete establishment of a three-dimensional finite element model of the total knee joints. The method is high in modeling efficiency, can solve the problem of extraction of the knee joint model, analyzes the stress behavior of the knee joint through numerical simulation, and is beneficial to knee joint protection, rehabilitation and prosthesis design and optimization.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

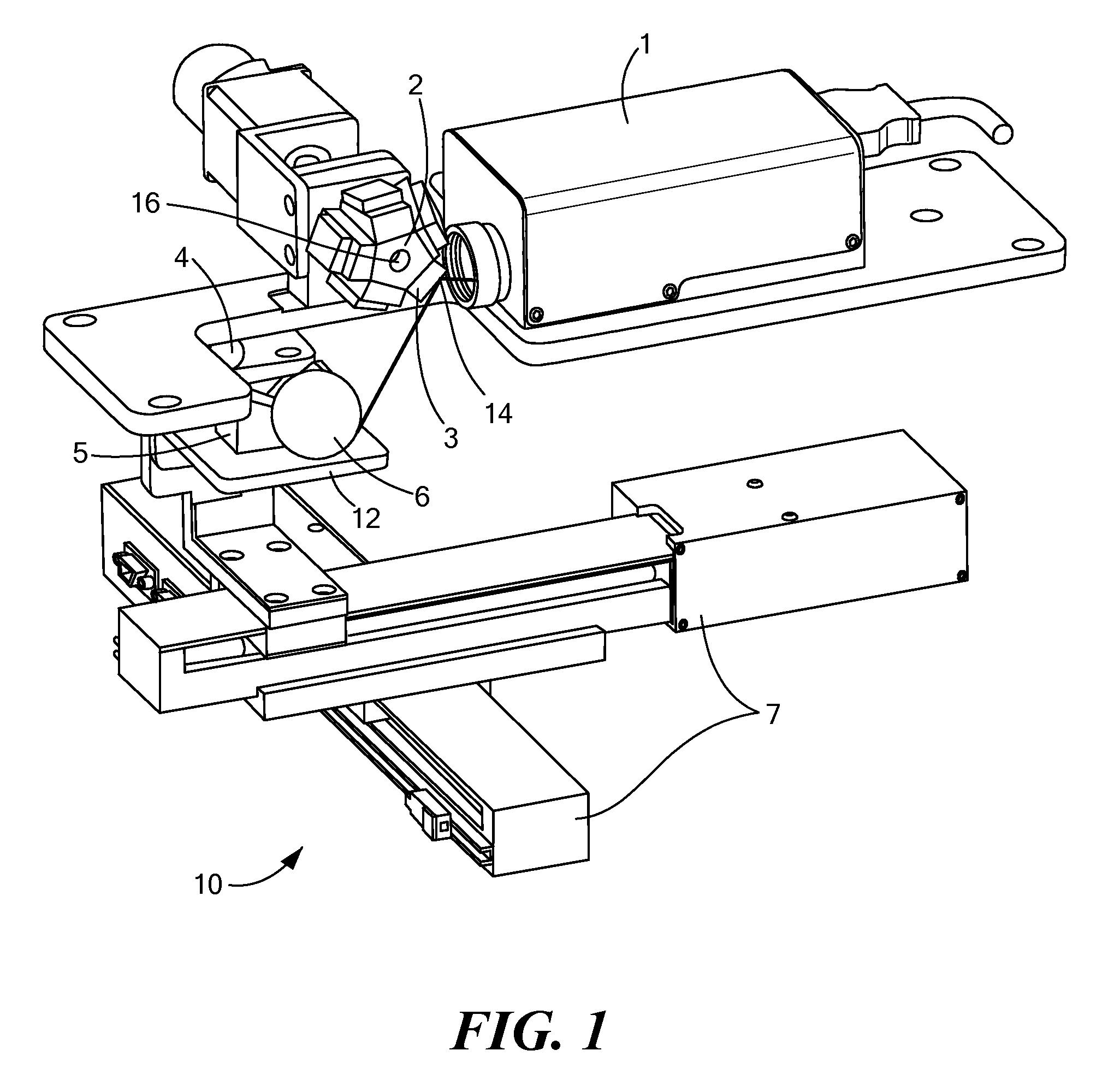

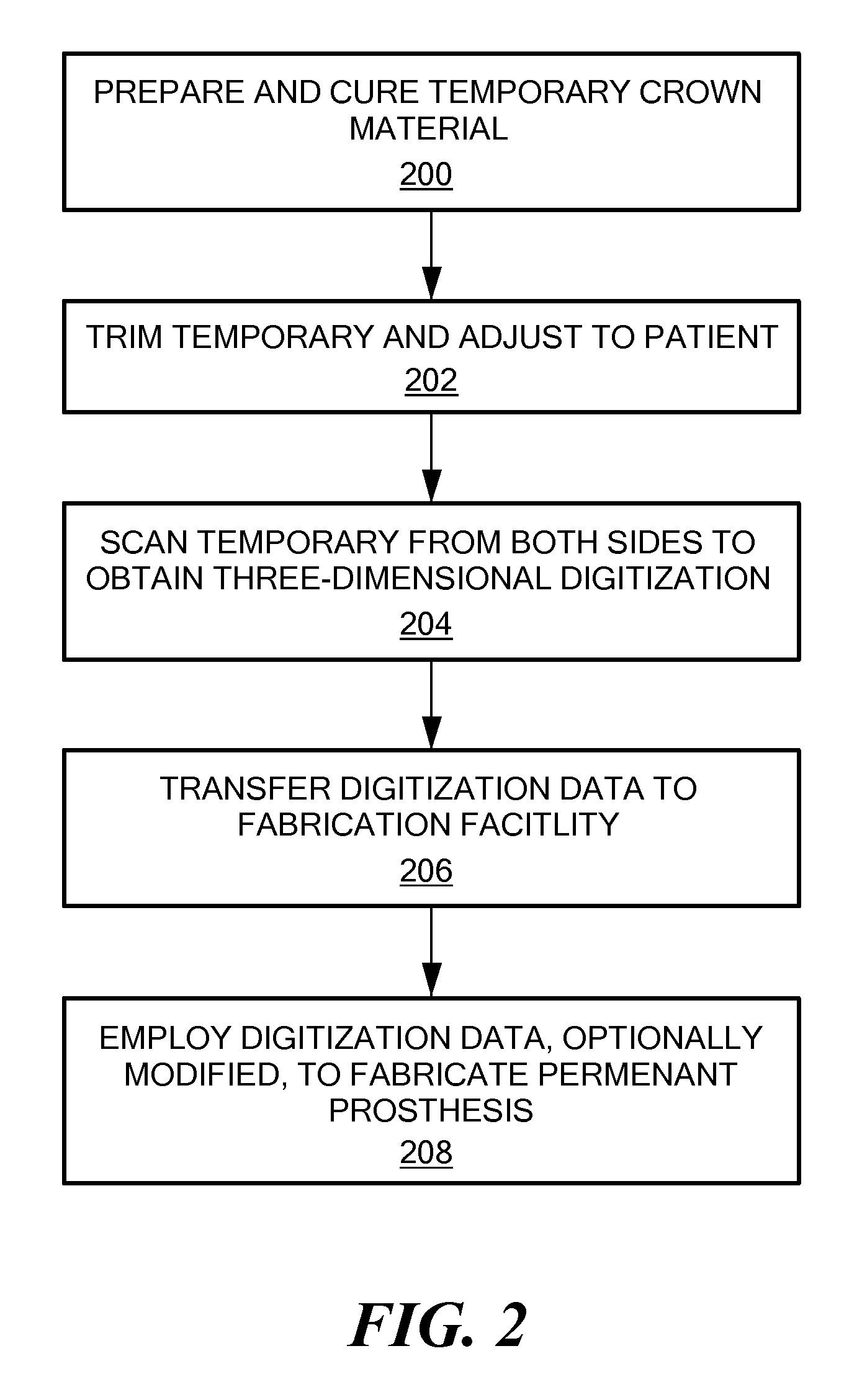

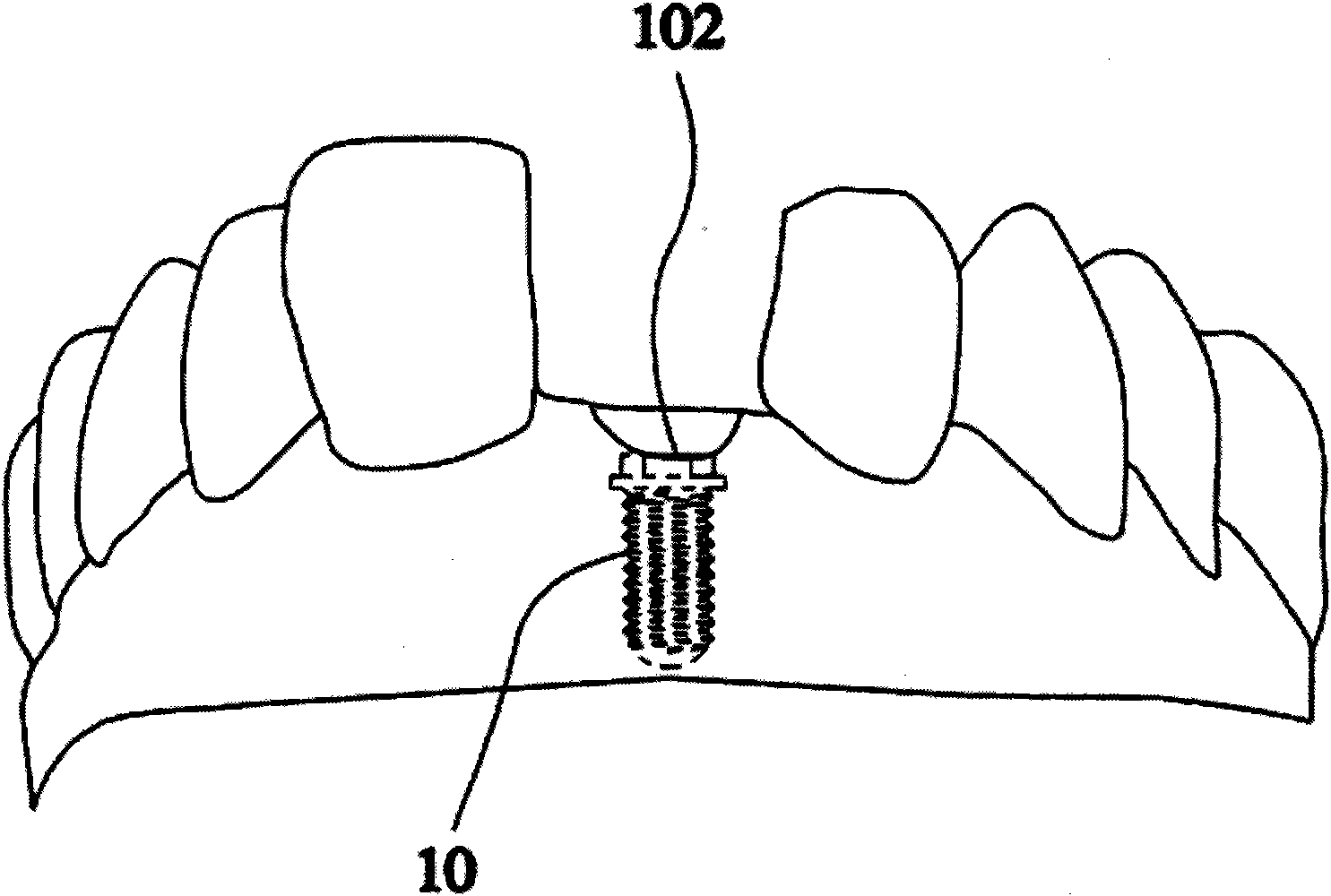

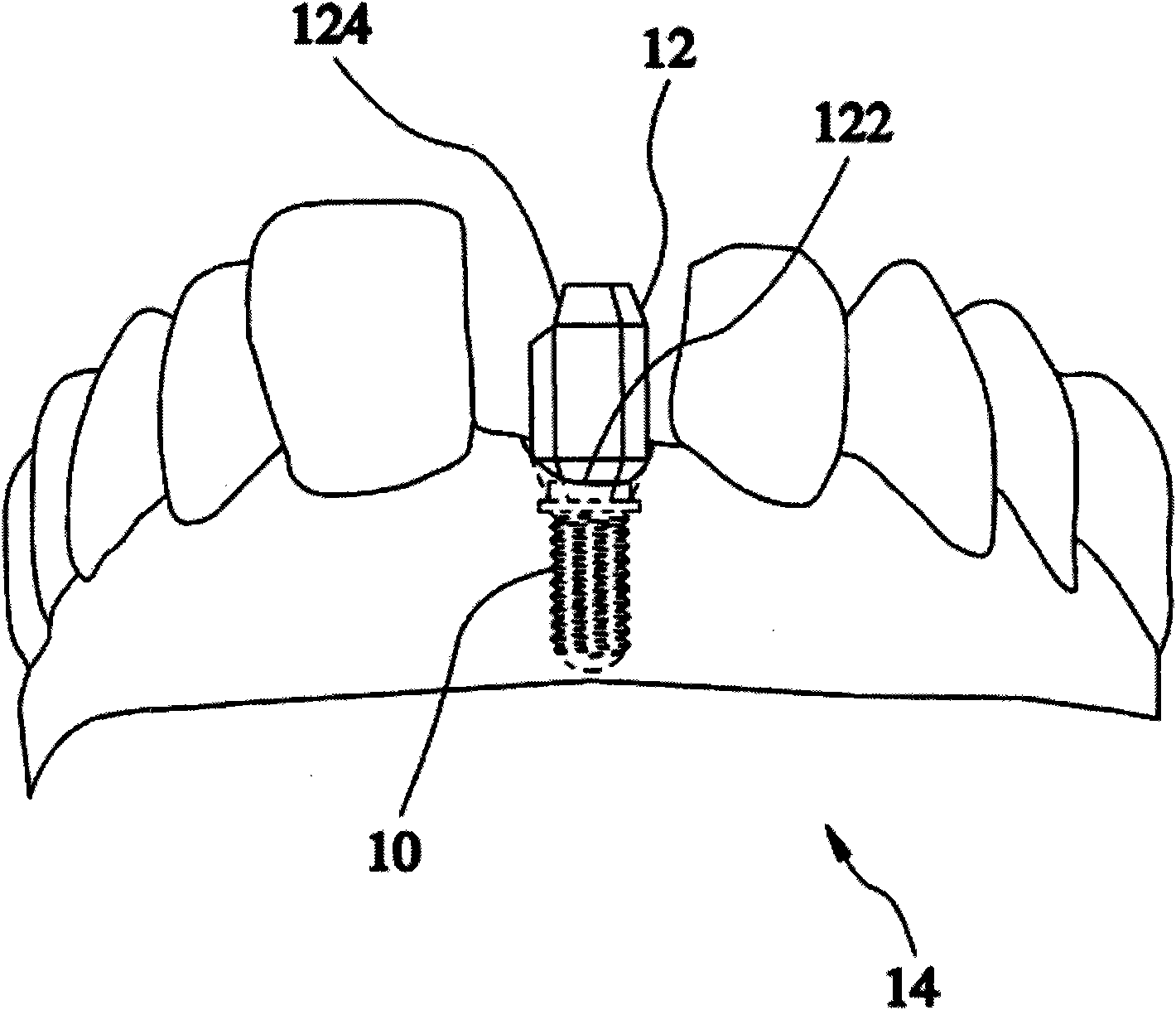

Dental Prosthesis Fabrication Based on Local Digitization of a Temporary

InactiveUS20090254299A1Mechanical/radiation/invasive therapiesDigital computer detailsDigital dataCo ordinate

A system and methods for obtaining and processing data requisite for fabrication of a dental restorative prosthesis. A dental temporary is fashioned at a site of patient treatment, and fitted in the patient's mouth. The temporary is then characterized by three-dimensional digital data based on distances measured by means of three-dimensional co-ordinate measuring equipment. The three-dimensional data are transmitted to a fabrication site, where a prosthesis may be fabricated. Additionally, information based upon the three-dimensional digital data characterizing the temporary may also be provided to a dentist at the site of patient treatment. The prosthesis design may be edited prior to fabrication.

Owner:OPTIMET OPTICAL METROLOGY

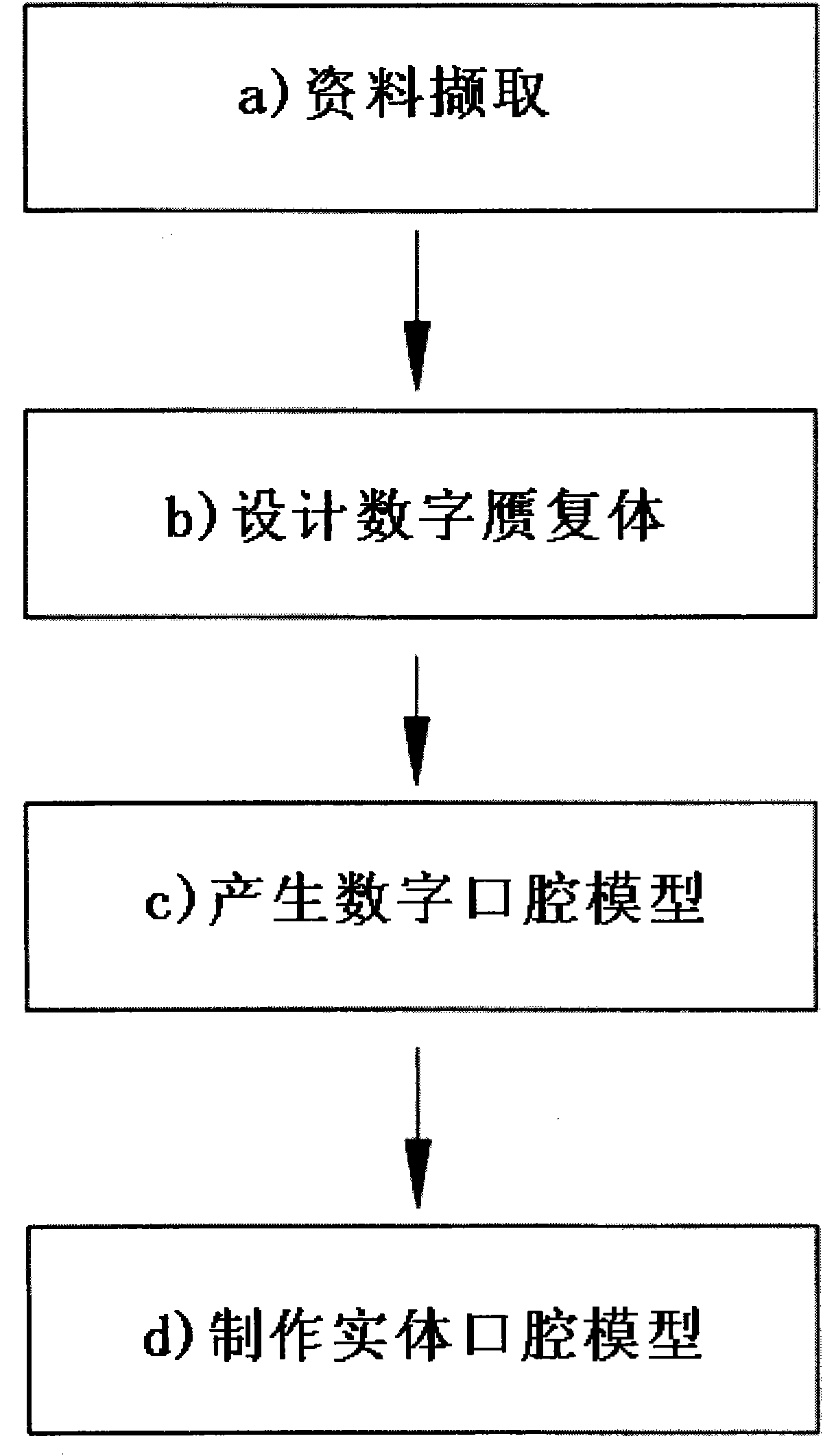

Method for producing digital model applied to dental implant and method for producing artificial teeth

InactiveCN102078225AEasy to operateReduce mistakesSpecial data processing applicationsDental prostheticsDigital dataDentures

The invention belongs to the technical field of dental implant and in particular relates to a method for producing a digital model applied to dental implant and a method for producing artificial teeth. The method for producing the digital model comprises the steps of: a) information capture: obtaining first oral cavity digital data and storing the data in a computer; b) digital prosthesis design; c) generation of a digital oral cavity model: generating the first digital oral cavity model through processing by using a second digital oral cavity model; and d) production of a solid oral cavity model. In the step of information capture, the first digital oral cavity data is obtained by scanning for only one time with simplified operating steps. After the first digital oral cavity data is obtained, the digital prosthesis can be designed, the first digital oral cavity model can be generated and the first solid oral cavity model can be produced simultaneously. No silica gel model needs to be produced into the oral cavity model and no production program is adopted to to produce artificial abutment teeth or a dental rod and then produce a dental crown or a dentalpad, thereby the error is reduced, the processing time is shortened and the produced physical oral cavity model is accurate.

Owner:DONGGUAN BAOYU FINE CERAMICS INDAL

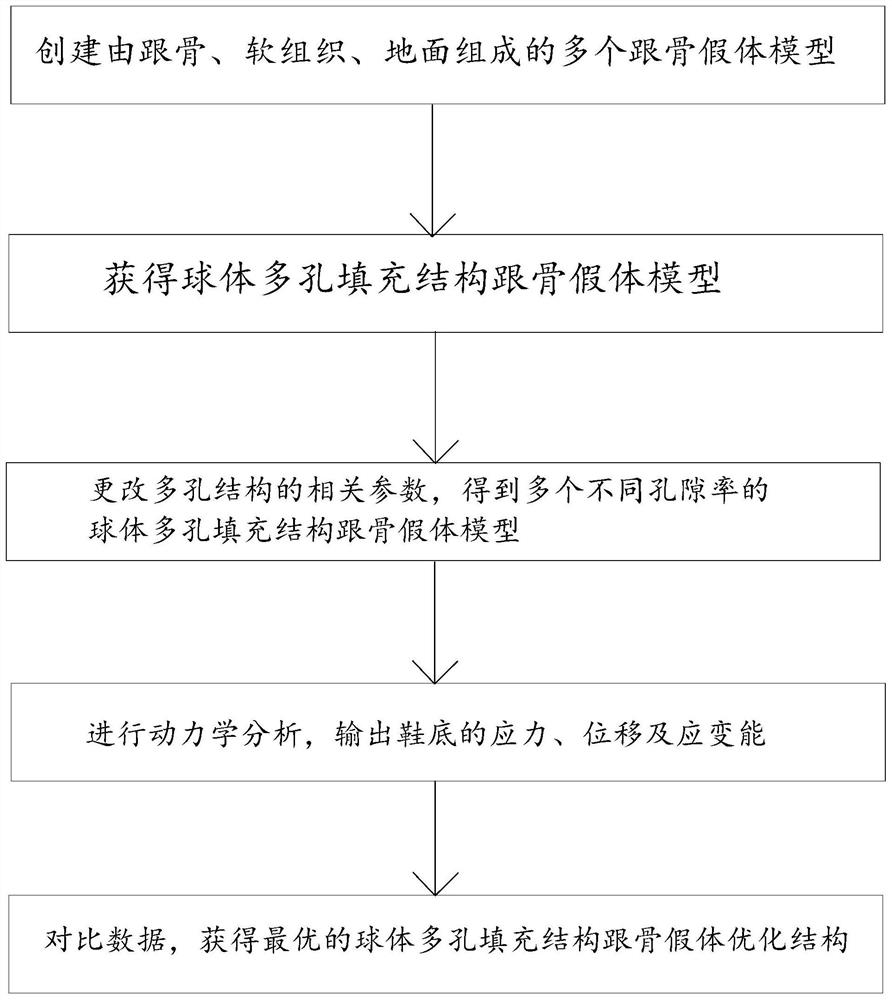

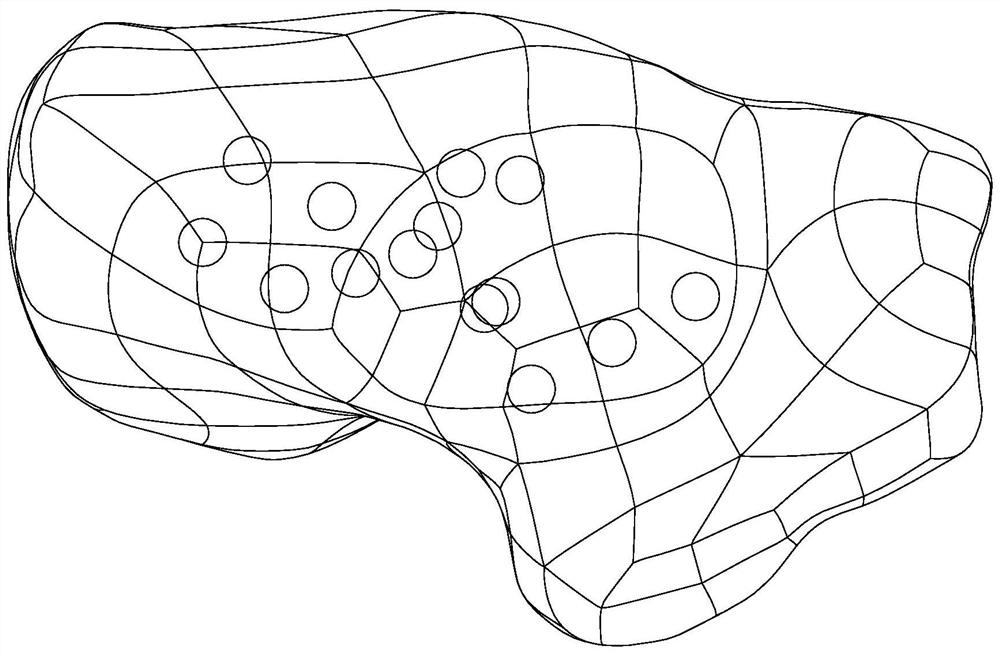

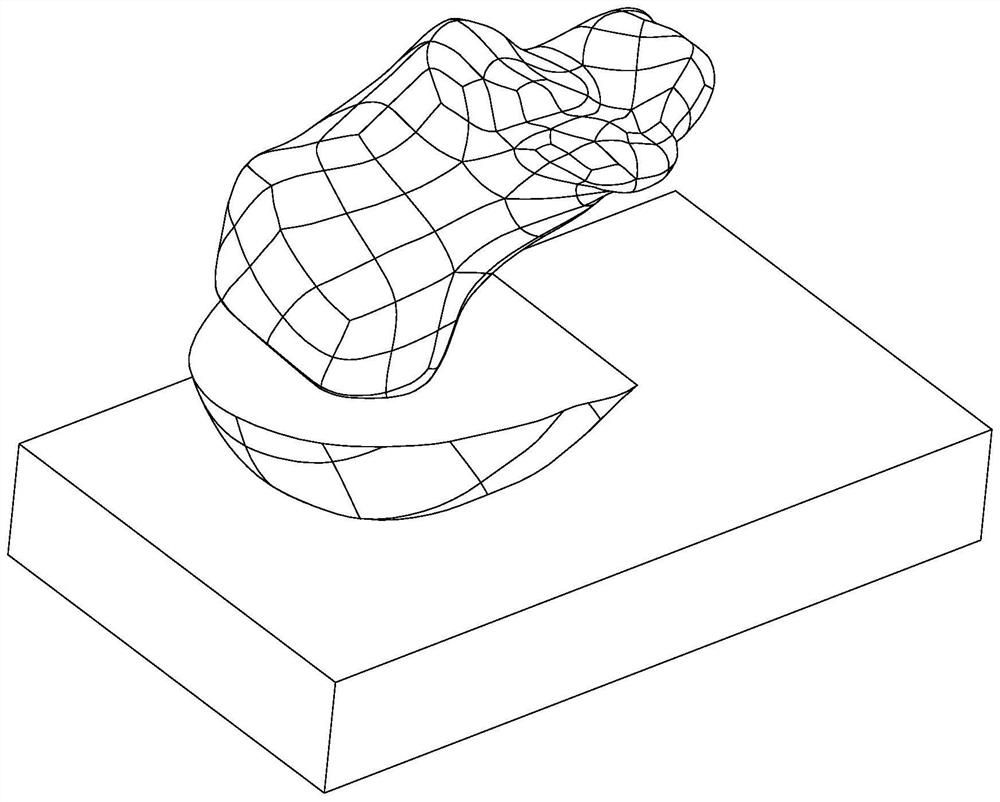

Spherical porous filling structure calcaneus prosthesis and optimization design method thereof

PendingCN112075990AReduce stress shielding effectMaximum strain energyMedical simulationComputer-aided planning/modellingFinite elemente analyseBiomedical engineering

The invention discloses a spherical porous filling structure calcaneus prosthesis design method. The method specifically comprises the following steps of S1, obtaining a calcaneus prosthesis model consisting of calcaneus, soft tissues and the ground; S2, performing porous structure modeling on the calcaneus model to obtain spherical porous filling structure calcaneus prosthesis models; S3, makingcombinations of different spherical radiuses r and array spacings a to obtain a plurality of spherical porous filling structure calcaneus prosthesis models; S4, performing finite element analysis on the models consisting of calcaneus prostheses, the soft tissues and the ground in ABAQUS to obtain data of strain energy, stress, displacement and the like of the calcaneus prostheses; and S5, comparing data of maximum strain energy, maximum stress, maximum displacement and the like of the spherical porous filling structure calcaneus prosthesis models with different porosities to obtain an optimalspherical porous filling structure calcaneus prosthesis optimization structure. The invention furthermore provides a spherical porous filling structure calcaneus prosthesis.

Owner:HUAQIAO UNIVERSITY

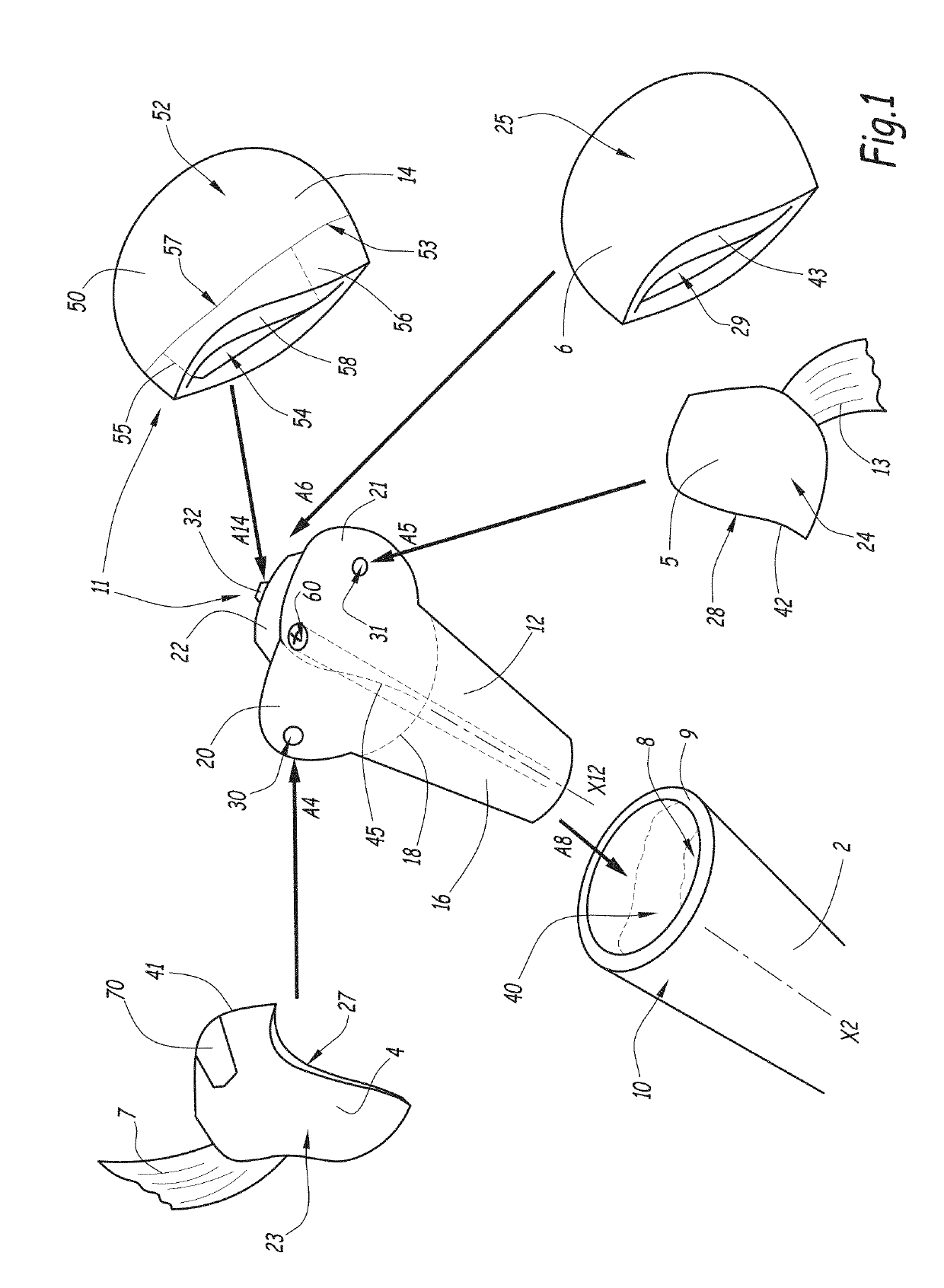

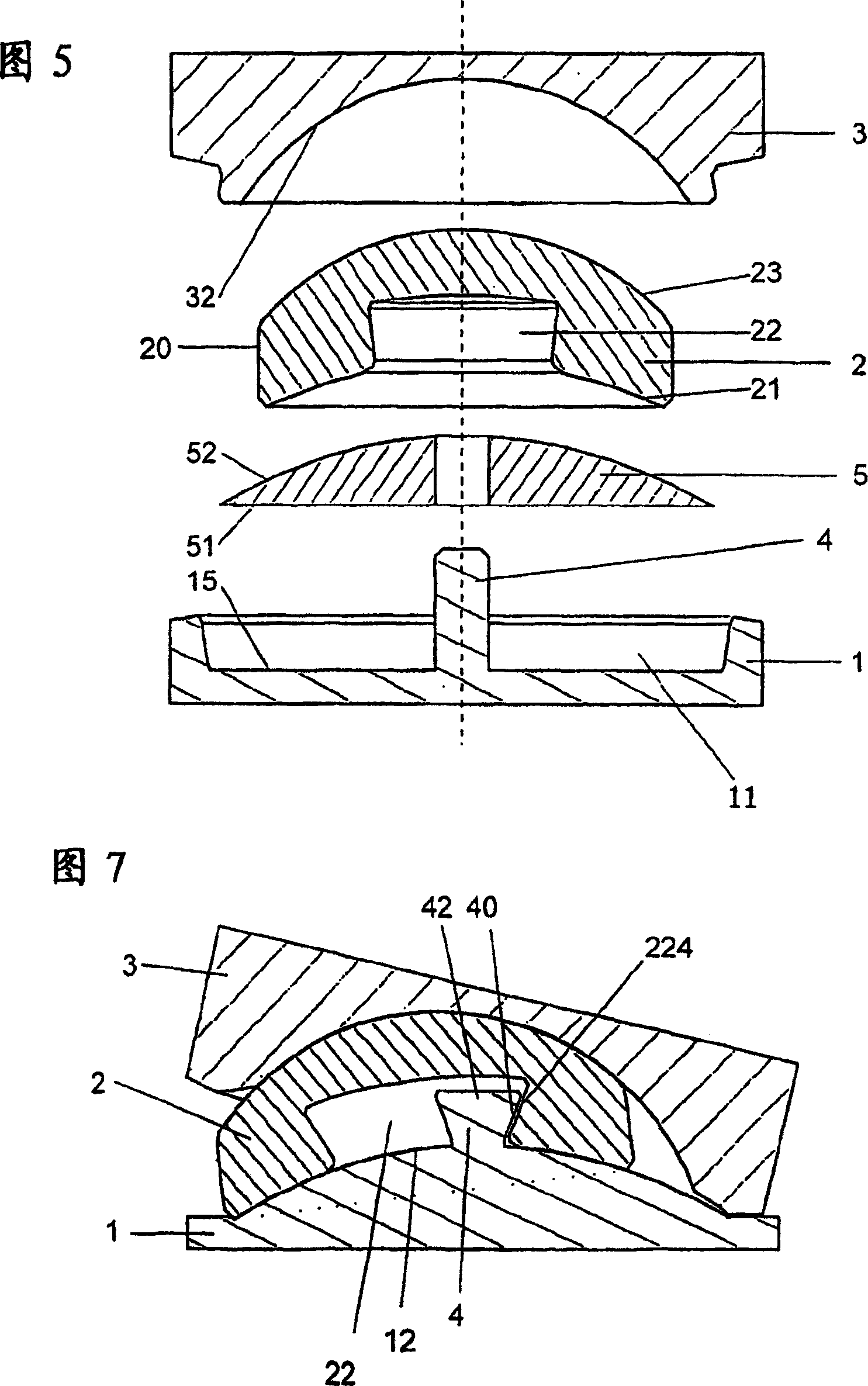

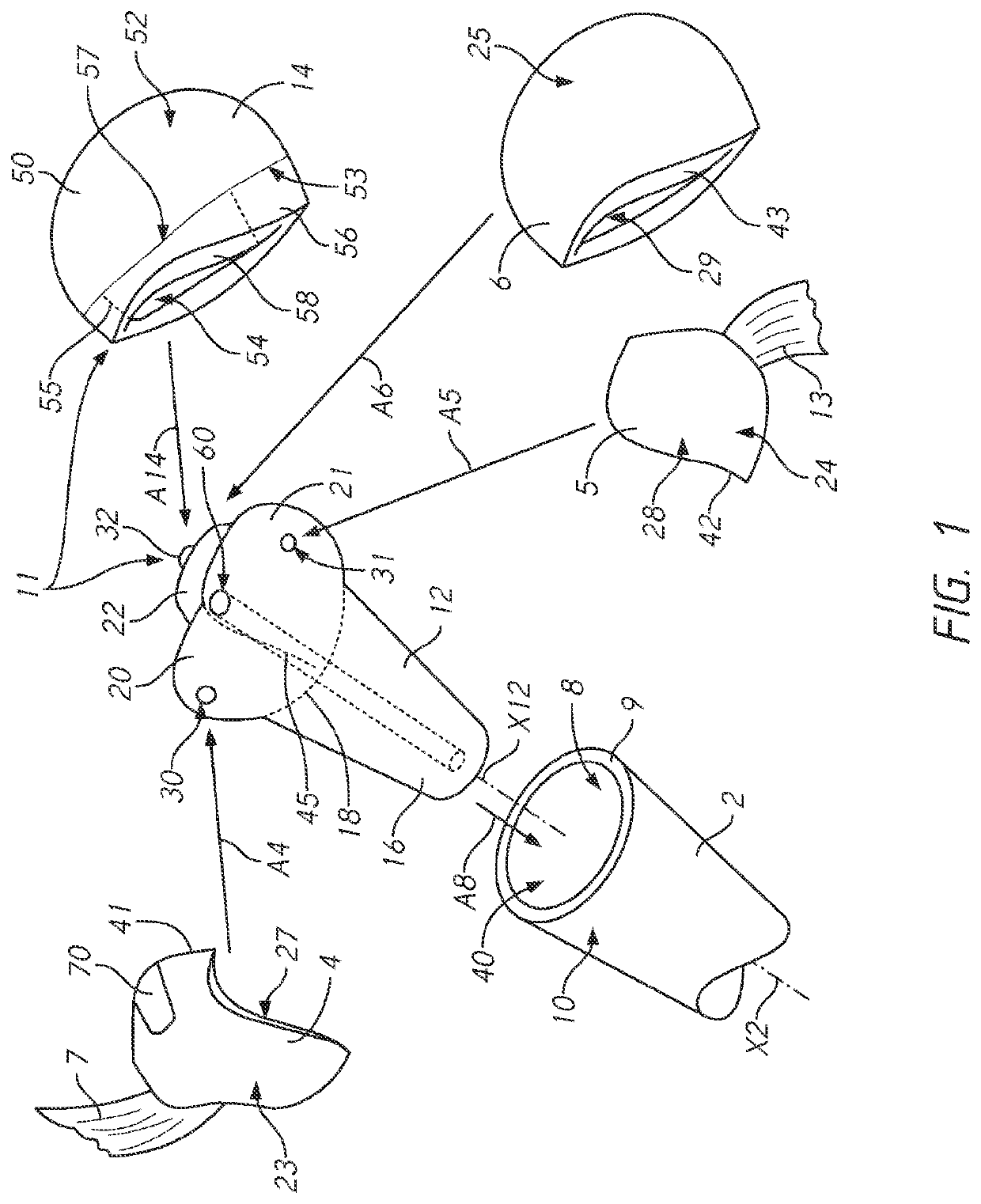

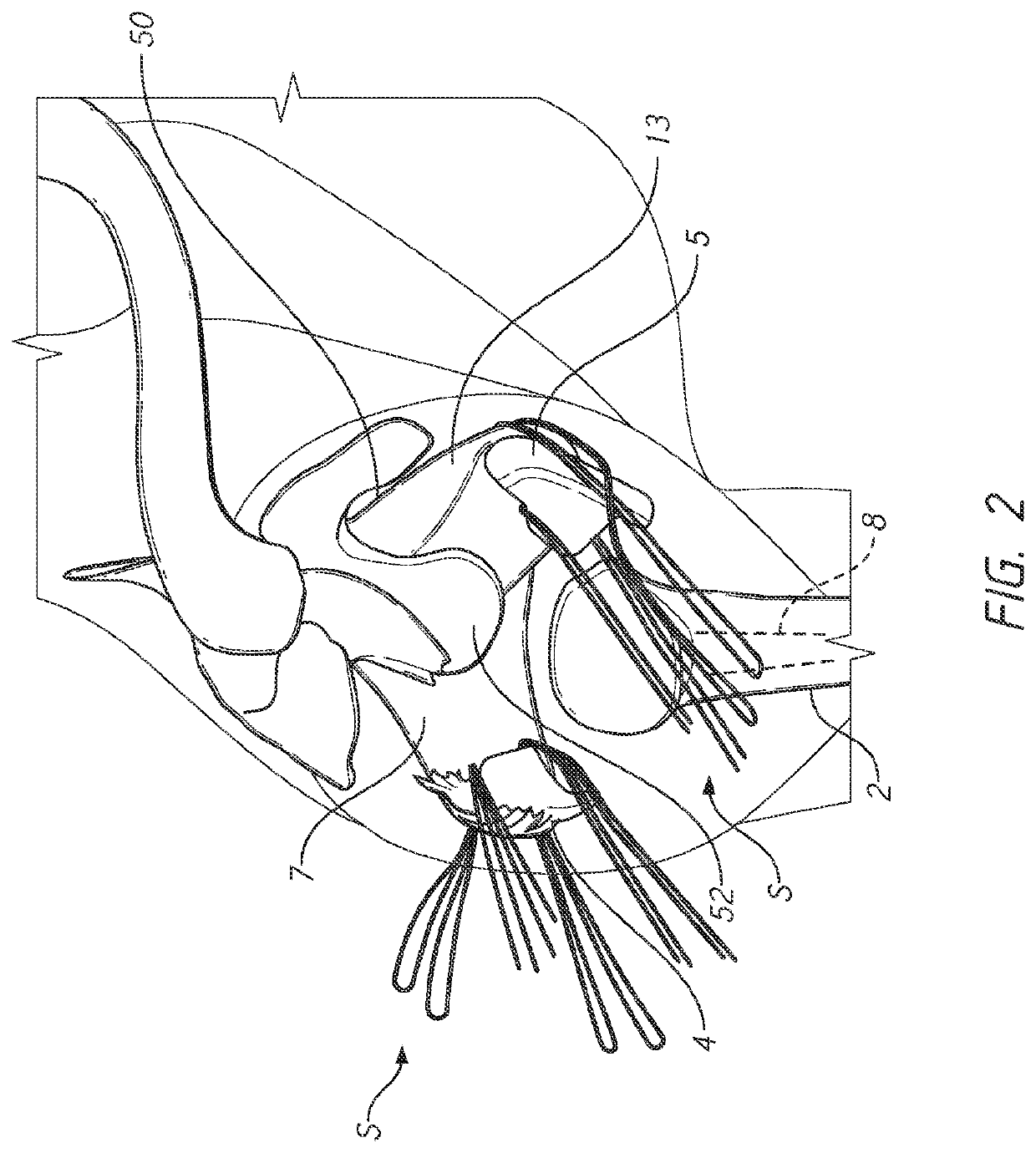

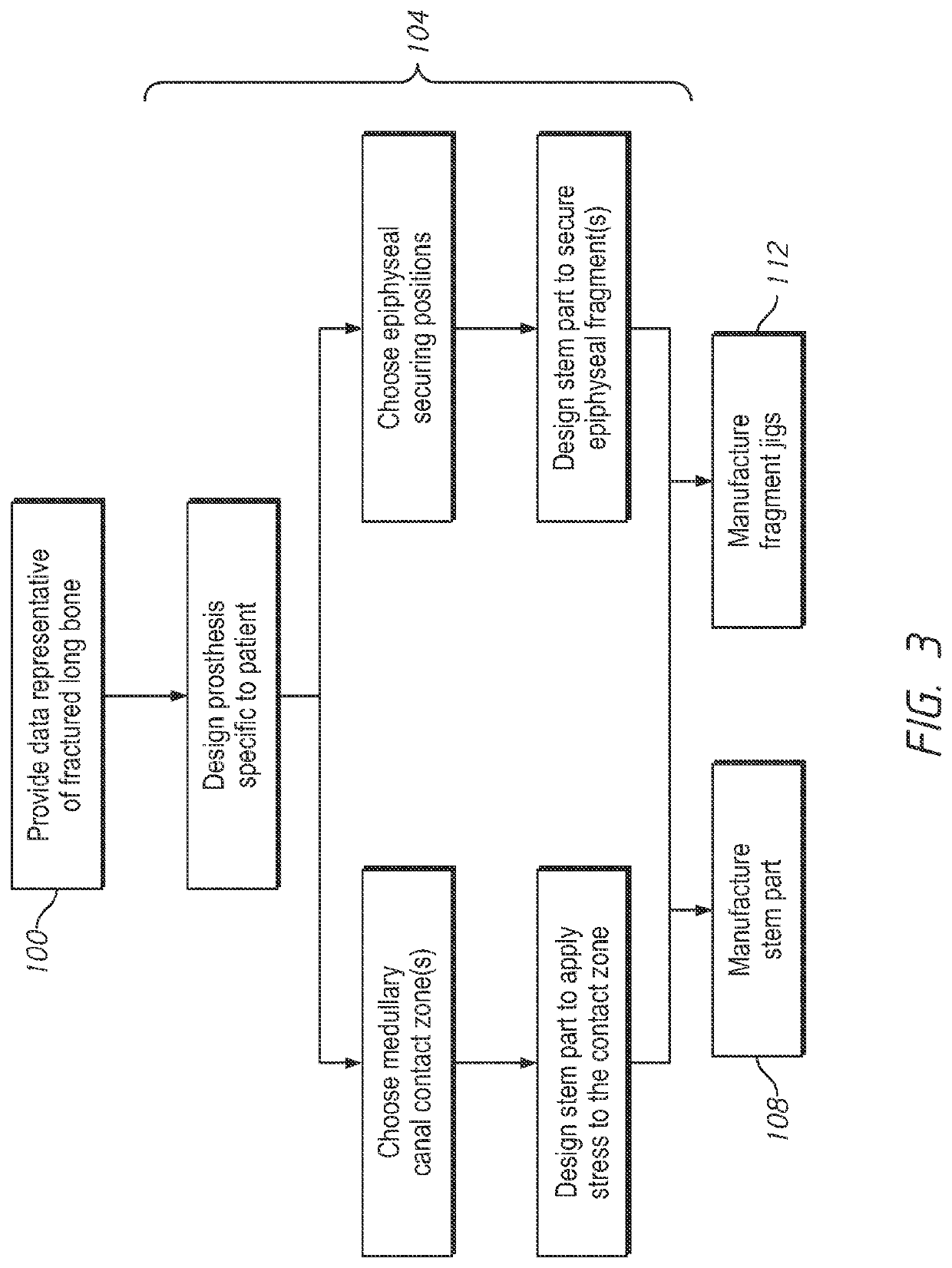

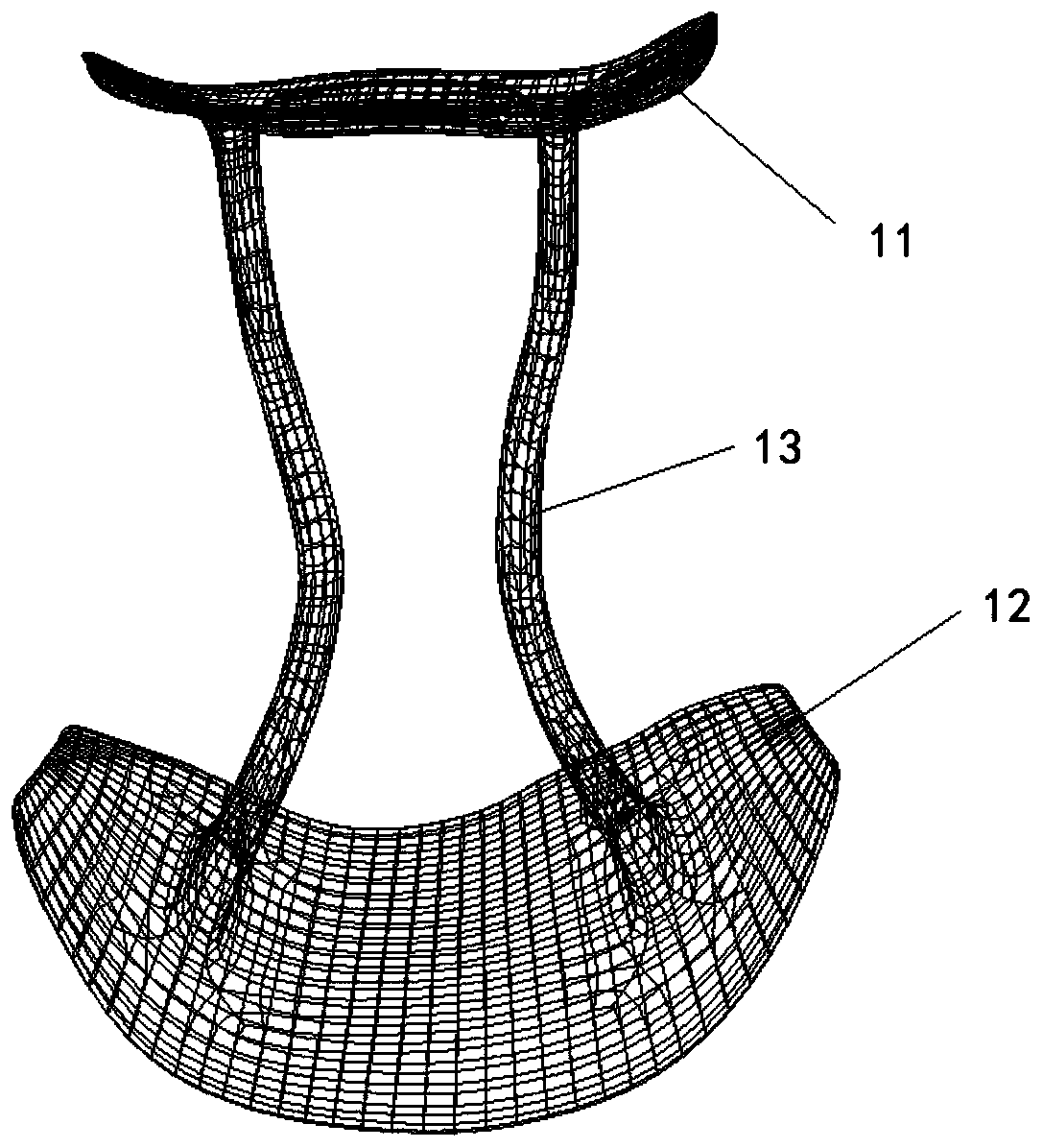

Method for manufacturing a patient-specific prosthesis for a fractured long bone

ActiveUS20190240030A1Reduce riskMechanical stress can be appliedInternal osteosythesisJoint implantsProsthesisBone marrow cavity

The invention concerns a method for manufacturing a prosthesis (11) for a fractured long bone of a patient, the method comprising the steps of: A) providing data representative of the fractured long bone, the fractured long bone comprising a diaphyseal fragment (2) comprising a medullary cavity (8); B) based on said data, designing the prosthesis specifically to the patient, the prosthesis comprising a stem part (12) configured to be inserted into the medullary cavity, step B) comprising: a sub-step of choosing, specifically to the patient, a contact zone (40) of the medullary cavity onto which a respective chosen mechanical stress is planned to be applied by the stem part, and a sub-step of designing the stem part so that the stem part may be inserted into the medullary cavity and thus apply the chosen mechanical stress to said contact zone; and C) manufacturing the prosthesis designed at step B).

Owner:HOWMEDICA OSTEONICS CORP

3D printing technique-based preoperative knee joint deformed bone model production method

InactiveCN105844702AReduce bleedingReduce mistakesAdditive manufacturing apparatusIncreasing energy efficiencyHuman bodyDigital imaging

The invention relates to a 3D printing technique-based preoperative knee joint deformed bone model production method. According to the method, based on alignment standards of the human body, knee joint digital imaging data are acquired; the digital imaging data are processed and then are inputted into computer aided design software for performing bone stratification and positioning; 1:1 operation design is performed on a digital 3D model and the bones of the human body; deformed bone removal is carried out through using the CAD according to a knee joint deformity state; a formed upper cut bone and lower cut bone are matched with each other along a longitudinal direction so as to be combined together; the imaging data of three generated cut bones are inputted into Materialise 3D modeling software for simulating the bones of the human body; three cut bone models are printed out through 3D printing; the three cut bone models are matched and combined with one another, so that a preoperative knee joint deformed bone model can be formed; and based on the bone model, bone cutting simulation operation is carried out in vitro, pre-shaping of a prosthesis to be implanted into a patient can be realized, personalized surgeries, customized prosthesis design and production can be realized authentically.

Owner:GENERAL HOSPITAL OF PLA

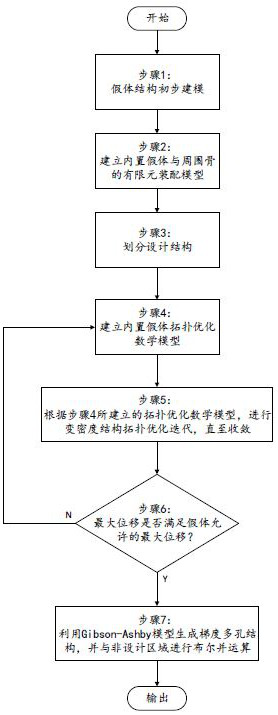

Endoprosthesis topological optimization mathematical model construction method and topological optimization design method

ActiveCN112233801AMedical simulationDesign optimisation/simulationMathematical modelOrthopedic department

The invention discloses an endoprosthesis topological optimization mathematical model construction method and a topological optimization design method, and relates to the technical field of orthopedicprostheses. The endoprosthesis topological optimization mathematical model construction method comprises the steps: calculating reference strain energy, calculating the sum of the strain energy, calculating normalized strain energy, establishing the maximum material retention rate and the maximum normal form stress of an endoprosthesis, calculating the average material retention rate of all unitsand the maximum value of the stress of geometric centers of all finite element units in a prosthesis containing area; and establishing and enabling the partial derivative of the normalized strain energy by a stiffness matching function to be zero to obtain a value of a weighting factor, substituting the value into the stiffness matching function, and establishing a topological optimization mathematical model. Healthy bones are used as reference of prosthesis design, the stiffness of the prosthesis is controllably adjusted to be close to reference strain energy by utilizing a weighting factorand an increase and decrease function, extreme value regulation and control of an optimization model function are realized by utilizing the mutual consumption effect of the increase and decrease function, so that convergence is stable, an optimal solution is conveniently obtained, and application of actual engineering is facilitated.

Owner:JIHUA LAB

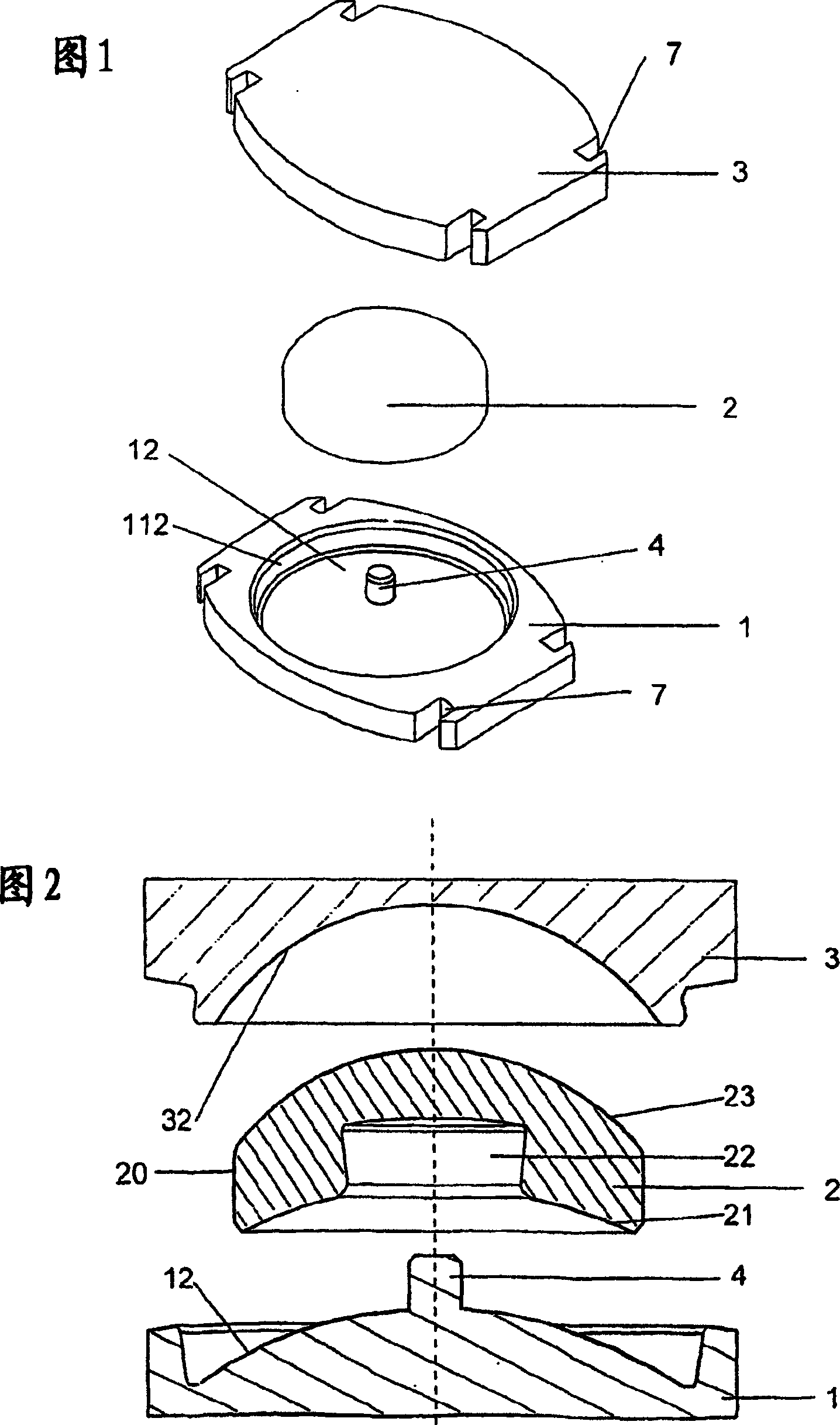

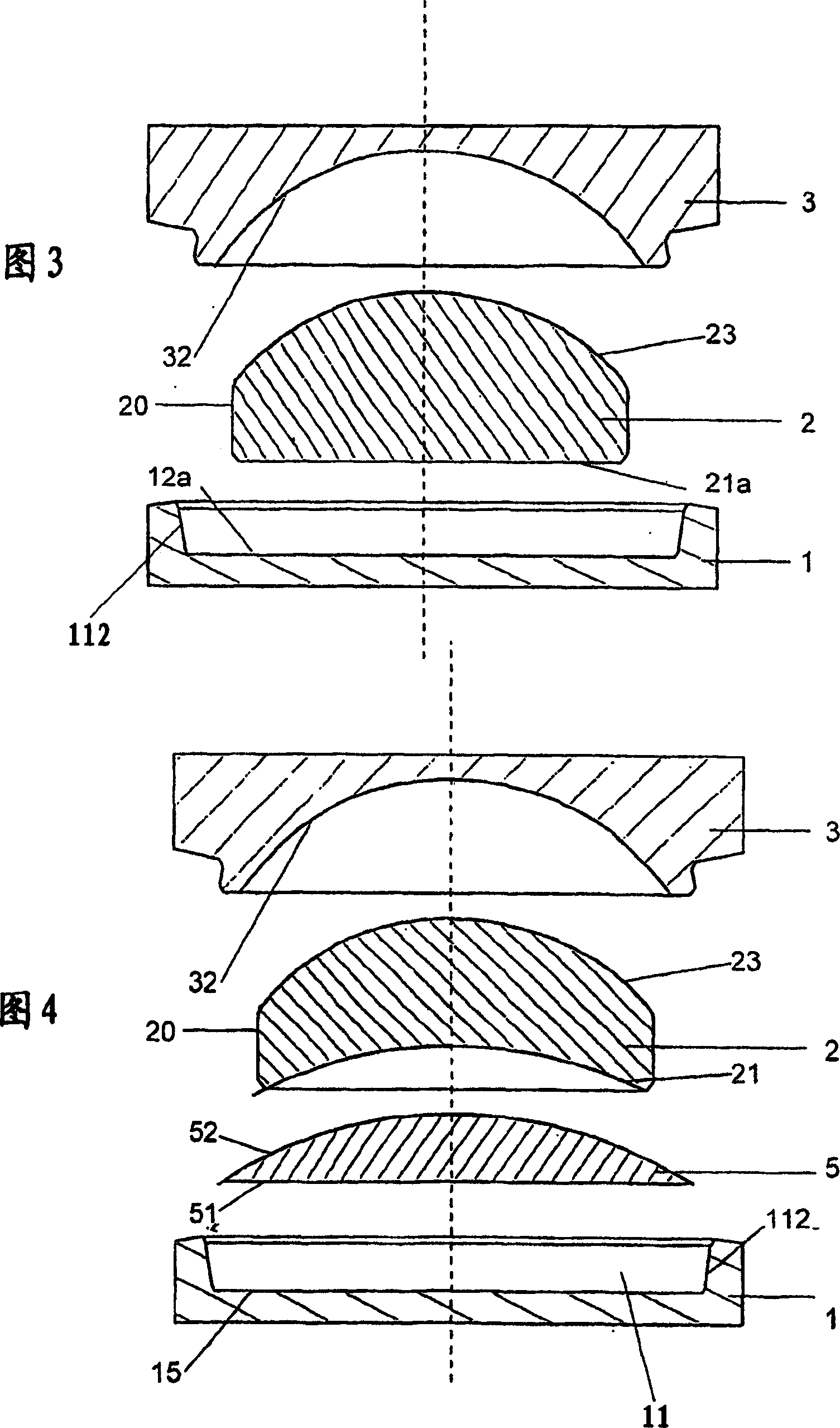

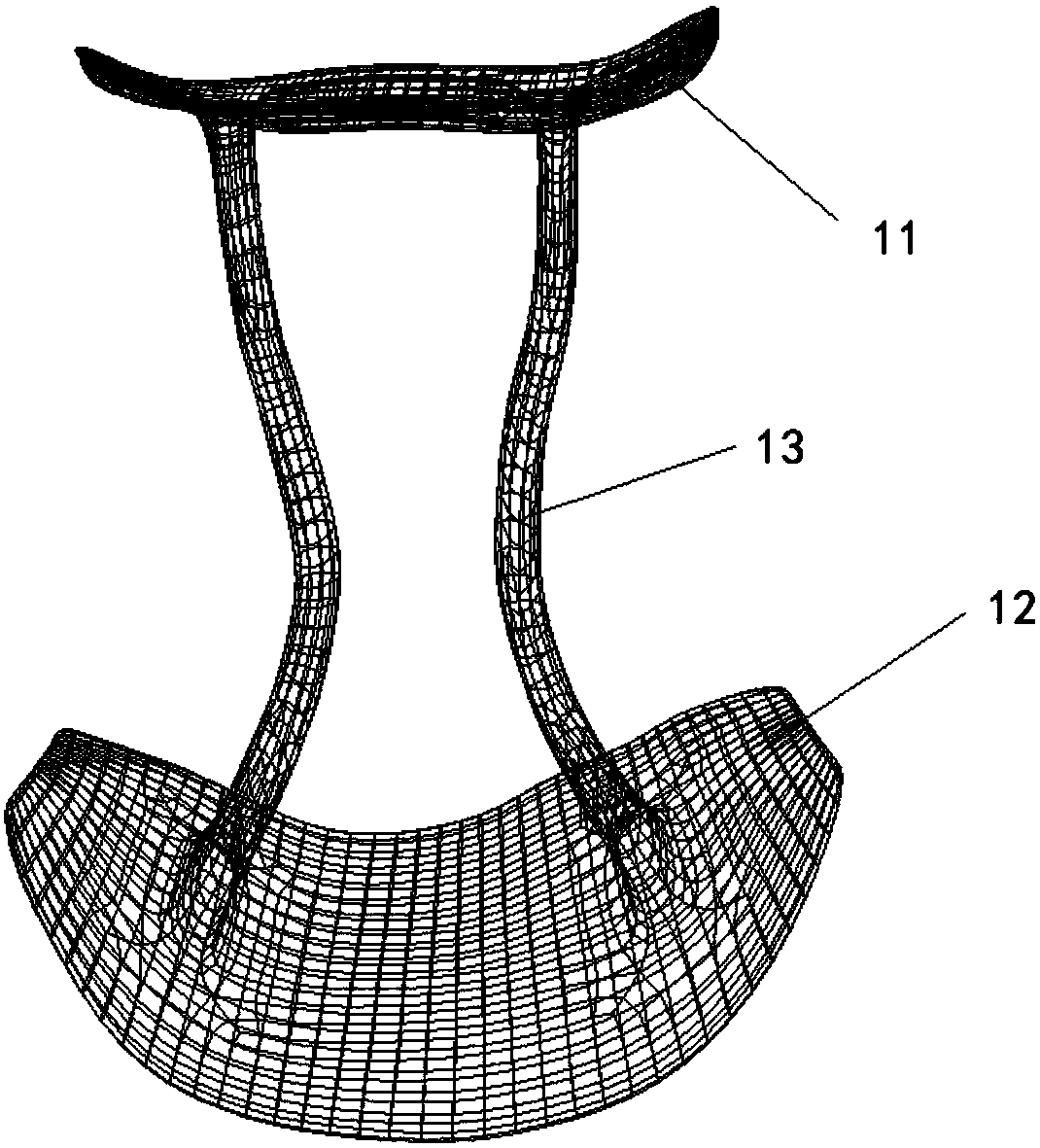

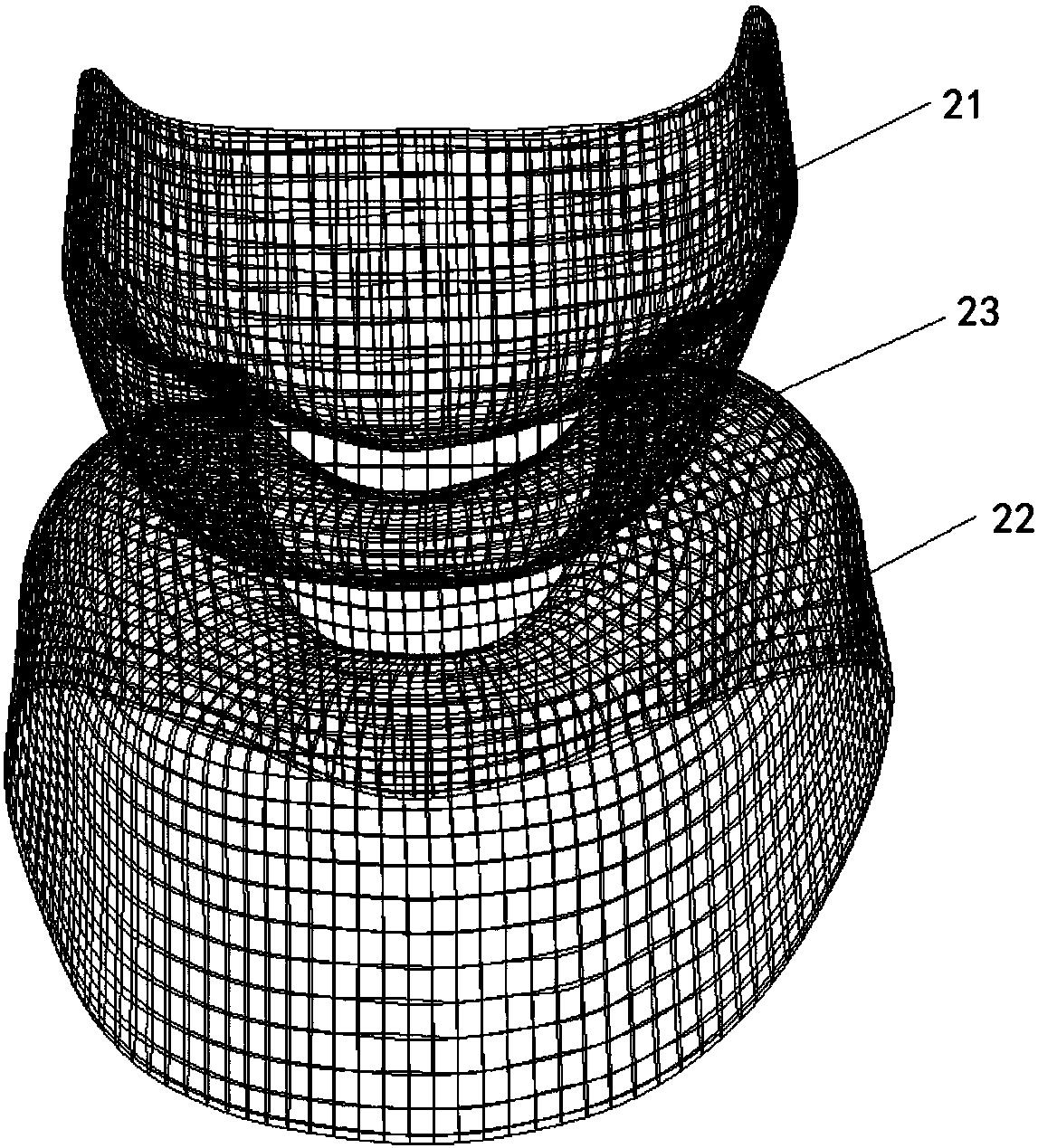

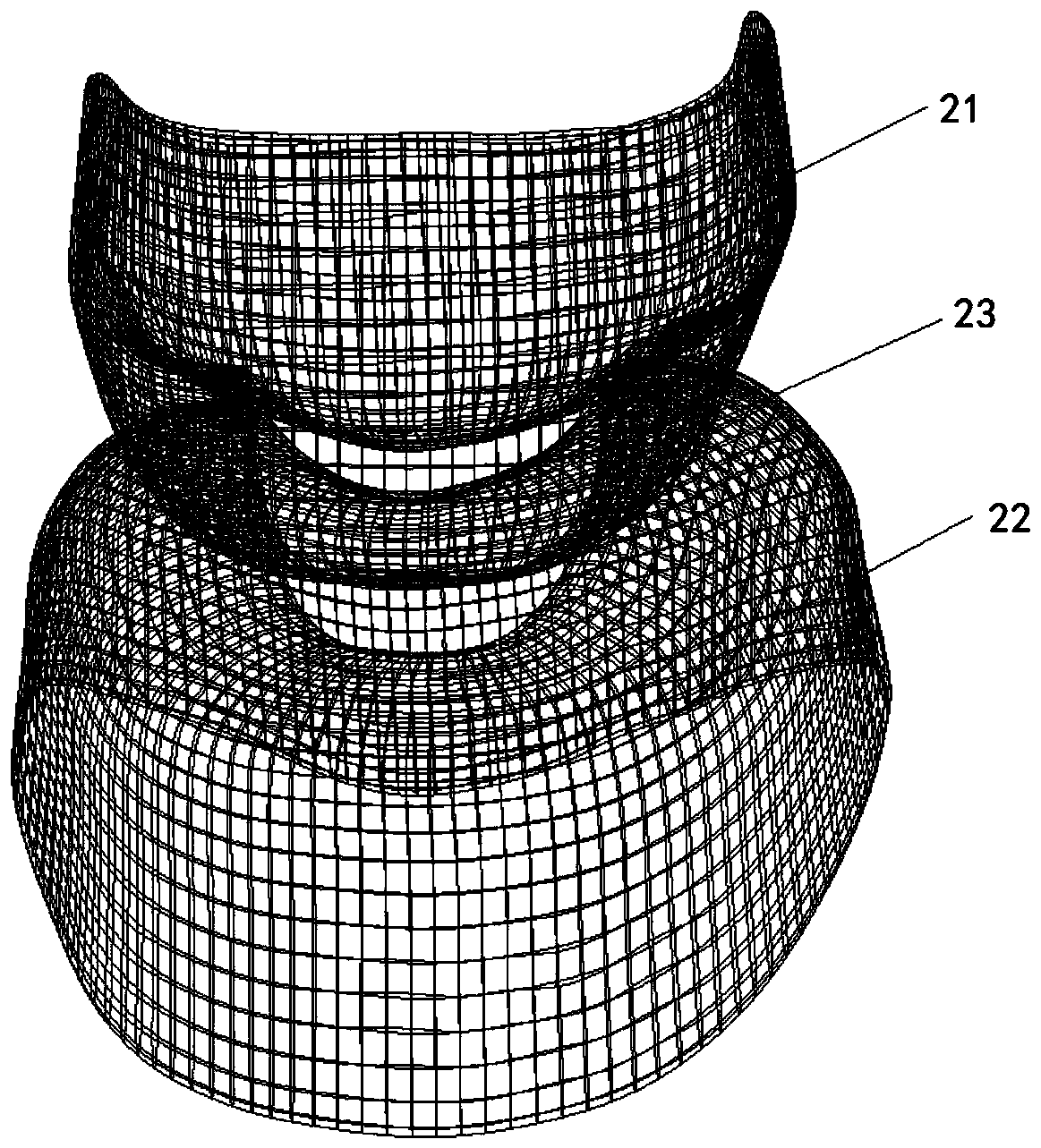

Intervertebral disc prosthesis and fitting tools

The present invention concerns an intervertebral disc prosthesis designed to be substituted for fibrocartilaginous discs ensuring connection between the vertebra of the vertebral column or the end of the latter. The invention increases stability of such a prosthesis by providing a translation or rotation stop to its nucleus (2), or inducing an angular correction between its plates (1, 3) in contact with vertebra, or a combination of these characteristics. Such a stop is obtained by parts (6, 20) external to the nucleus, and using contact surfaces perpendicular to their contact directions. Such a stop allow a better stability together with the enforcement of such an angular correction, induced by an angle (a3) between loadbearing surfaces (21, 23) of the nucleus.

Owner:LDR MEDICAL SAS

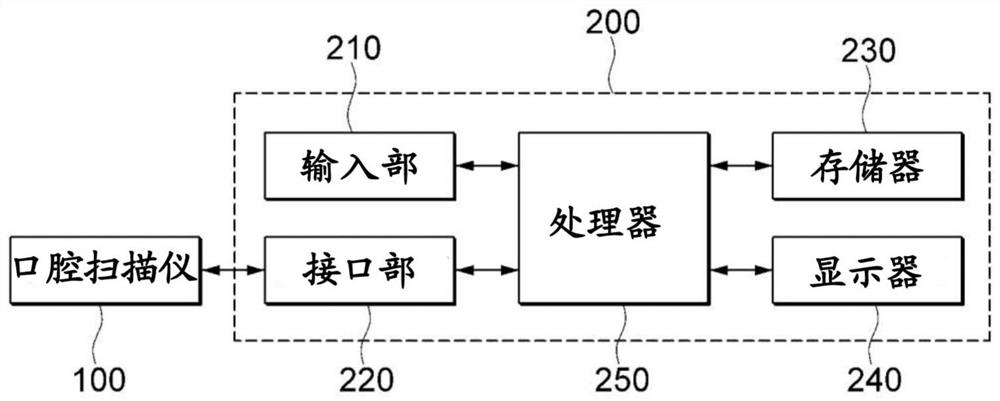

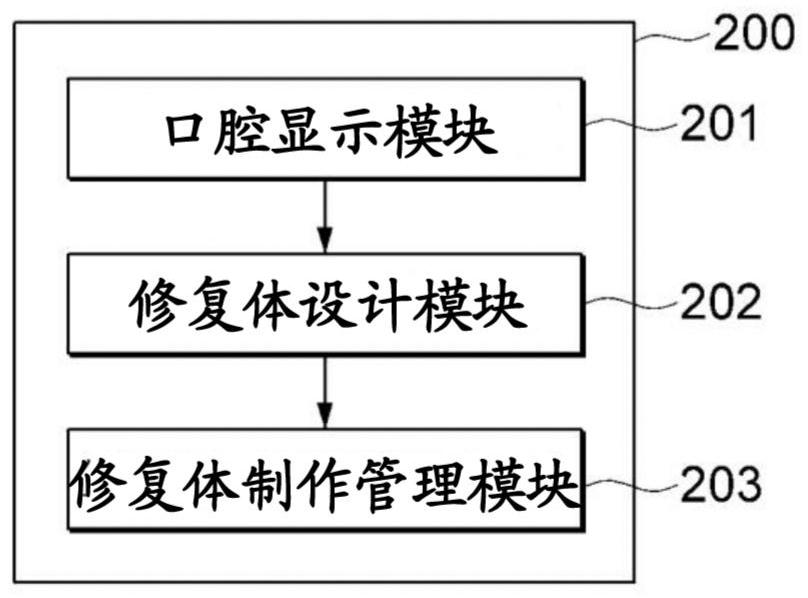

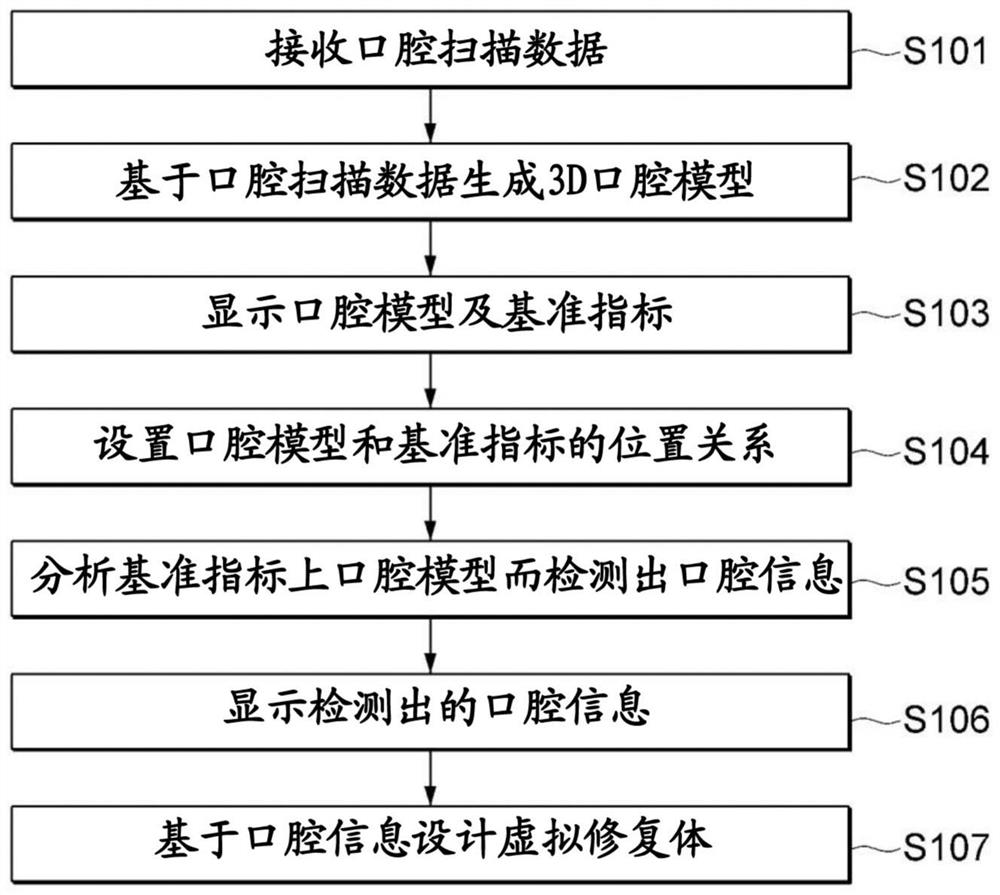

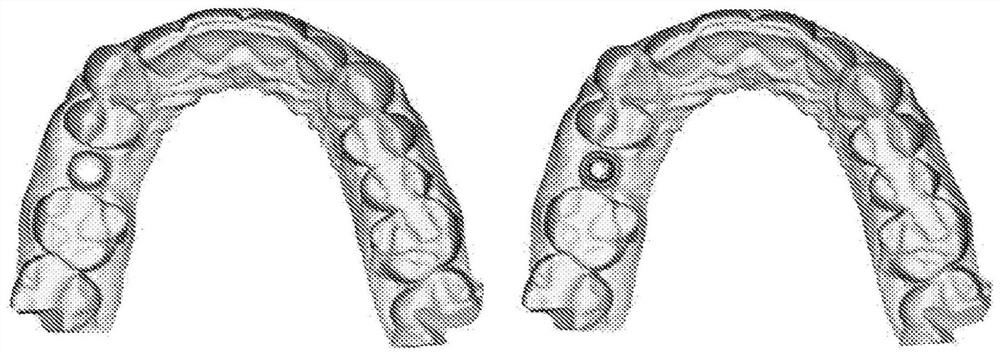

Three-dimensional oral model analysis method and prosthesis design method including same

ActiveCN112243366AAccurately obtainedEasier and faster to designImage enhancementImpression capsProsthesisDentistry

Owner:DDS

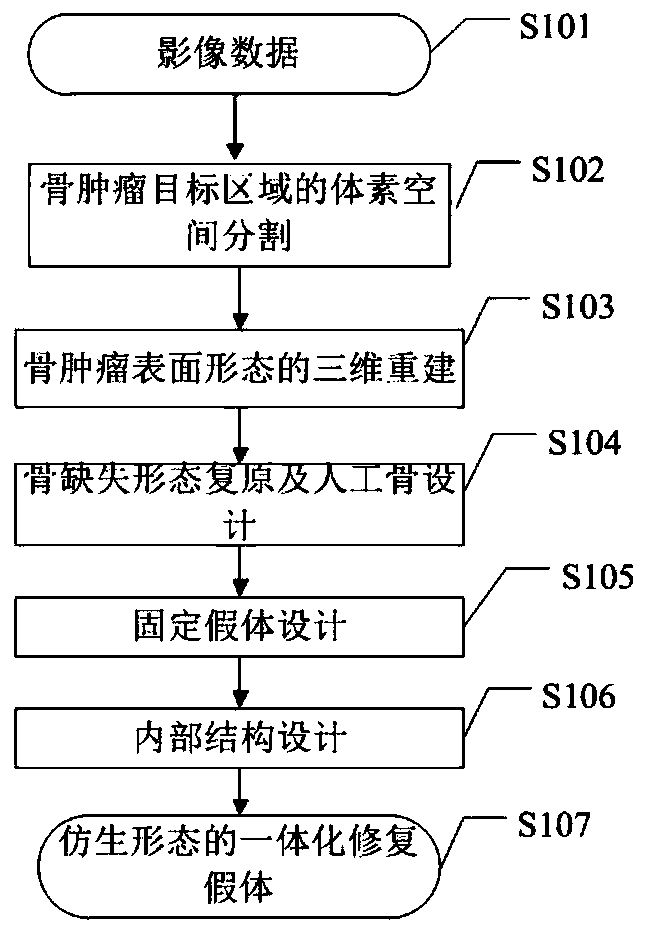

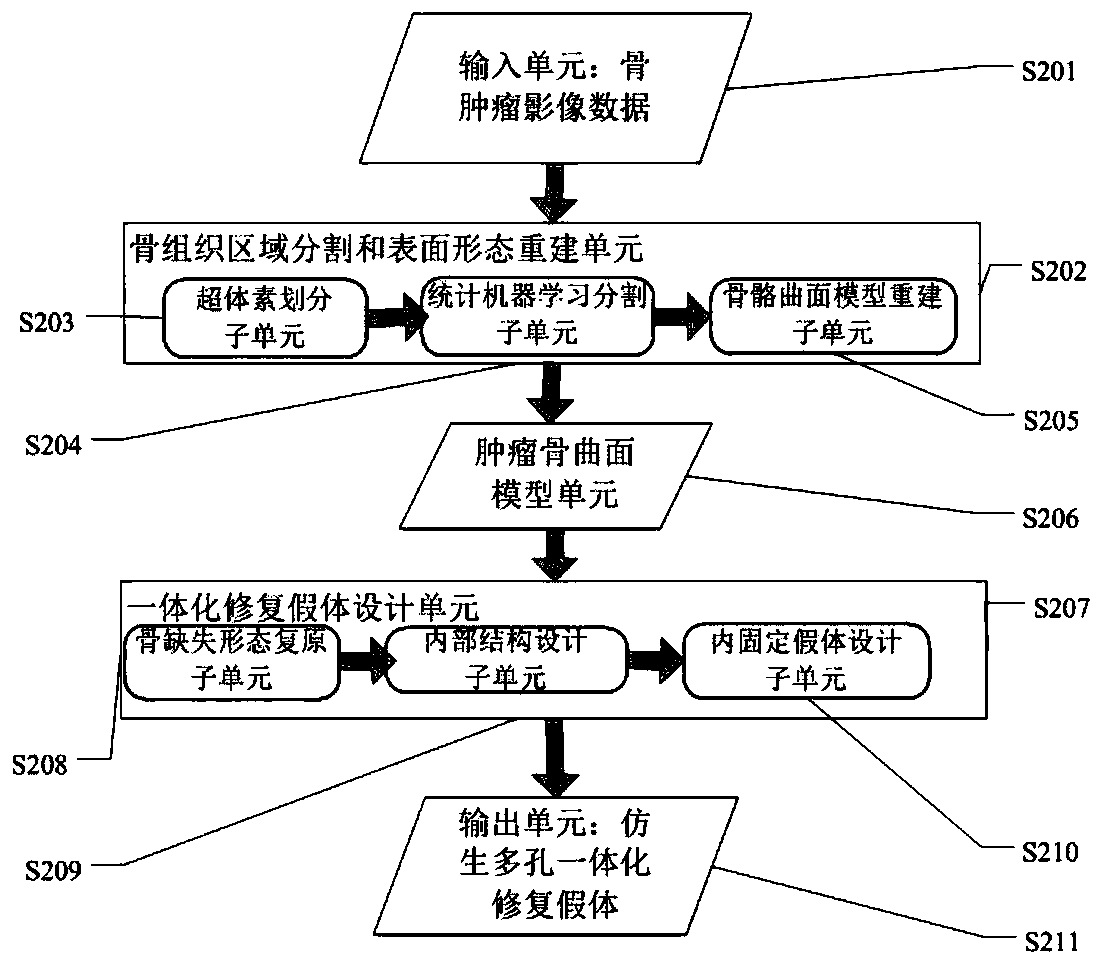

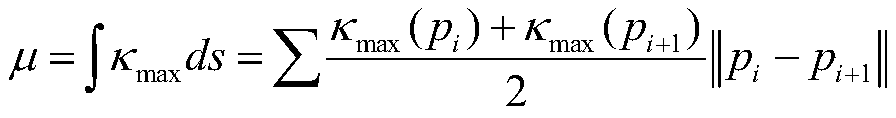

A bone tumor bionic repair system

ActiveCN109934925AGood biocompatibilityImprove mechanical propertiesImage analysis3D modellingModel reconstructionBiocompatibility Testing

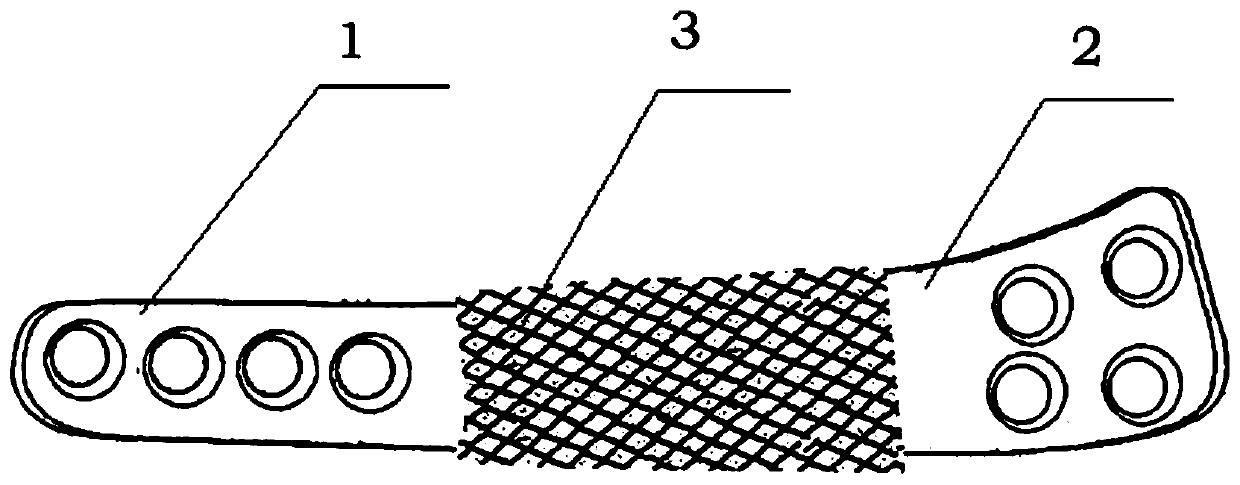

The invention discloses a bionic repair system for bone tumors and belongs to the field of computer-aided biomedical engineering and the system comprises a bone tumor image data input unit, a bone tissue region segmentation and surface morphology reconstruction unit, a bone tumor curved surface model unit, an integrated restoration prosthesis design unit and a bionic multi-cavity integrated restoration prosthesis output unit. Wherein the bone tissue region segmentation and surface morphology reconstruction unit comprises a supervoxel division subunit, a statistical machine learning segmentation subunit and a bone curved surface model reconstruction subunit; The integrated restoration prosthesis design unit comprises a bone loss form restoration subunit, an internal structure design subunitand an internal fixation prosthesis design subunit; According to the personalized and precise bone tumor repair system constructed by the invention, the automation of the design process is improved,and the complexity and inconvenience of the design process are reduced, so that the final repair prosthesis has good biocompatibility and mechanical property.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Three-dimensional (3D) printing tubular porous titanium alloy prosthesis for limb large-segment bone defect and preparation method of 3D printing tubular porous titanium alloy prosthesis

PendingCN110200727APromote bone growthImprove stabilityBone implant3D printingWater bathsPlasma electrolytic oxidation

The invention relates to three-dimensional (3D) printing tubular porous titanium alloy prosthesis for limb large-segment bone defects and a preparation method of the 3D printing tubular porous titanium alloy prosthesis. The preparation method comprises the following steps: designing hollow tubular porous titanium alloy prosthesis with a bone fracture plate according to thin-layer computed tomography (CT) scanning data of a patient in combination with an operation path and an osteotomy plane shape of a lesion part, and introducing the prosthesis design data into metal 3D printing equipment to prepare a tubular porous titanium alloy prosthesis; placing the prepared tubular porous titanium alloy prosthesis in an electrolyte of calcium acetate and beta sodium glycerophosphate to carry out micro-arc oxidation treatment on the tubular porous titanium alloy prosthesis, and then treating the tubular porous titanium alloy prosthesis in a constant-temperature water bath to obtain a 3D printing tubular titanium alloy prosthesis with titanium oxide on the surface; placing the 3D printing tubular titanium alloy prosthesis with titanium oxide on the surface in a Ba (OH) 2 solution and adjustingthe pH to 13 to react to form barium titanate on the surface of the 3D printed tubular titanium alloy prosthesis of titanium oxide. By the surface active treatment, the biocompatibility of the prosthesis is improved, new bone growth is induced, and a good bone integration effect is achieved; and the integrated bone fracture plate is high in fit degree with a backbone, and fixation reliability is improved. No additional auxiliary internal fixation is required.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

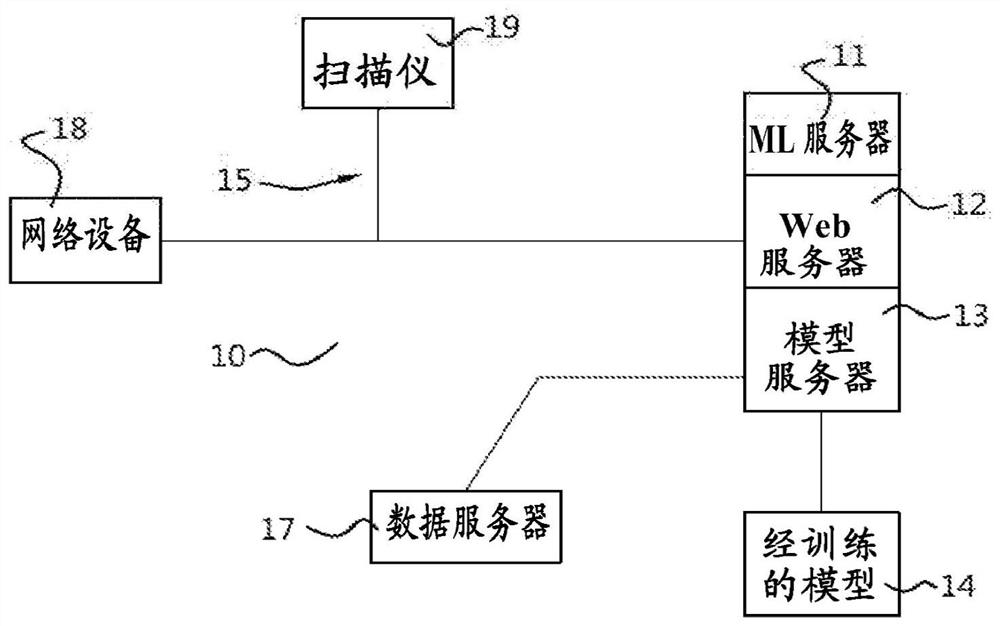

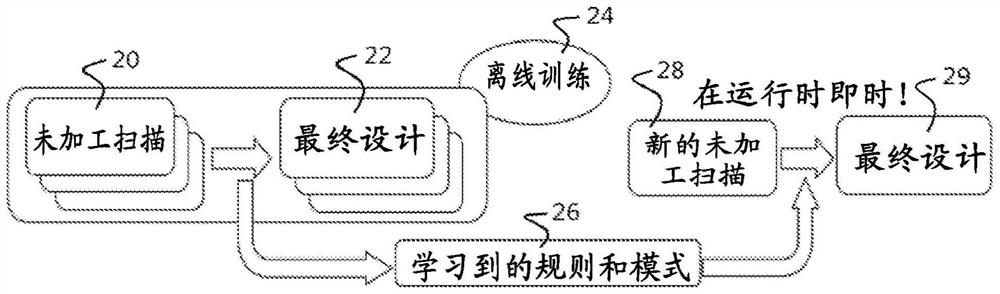

Method, system and apparatus for customizing immediate automated design of dental object

Embodiments of the present invention provide methods, systems, devices, and software for providing customized, clinically related designs in real time as needed, such as treatment plans / solutions for at least a single tooth replacement therapy, to enable immediate confirmation of the effectiveness and execution of patient-specific treatment solutions. Machine learning algorithms are used in computer-implemented methods or systems for automated prosthesis design. The prosthetic designs include designs of prosthetic elements such as dental crowns and abutments. Software for performing a method when executed on a digital processor is provided. Also included is fabrication of the repairable element.

Owner:DENTSPLY SIRONA INC

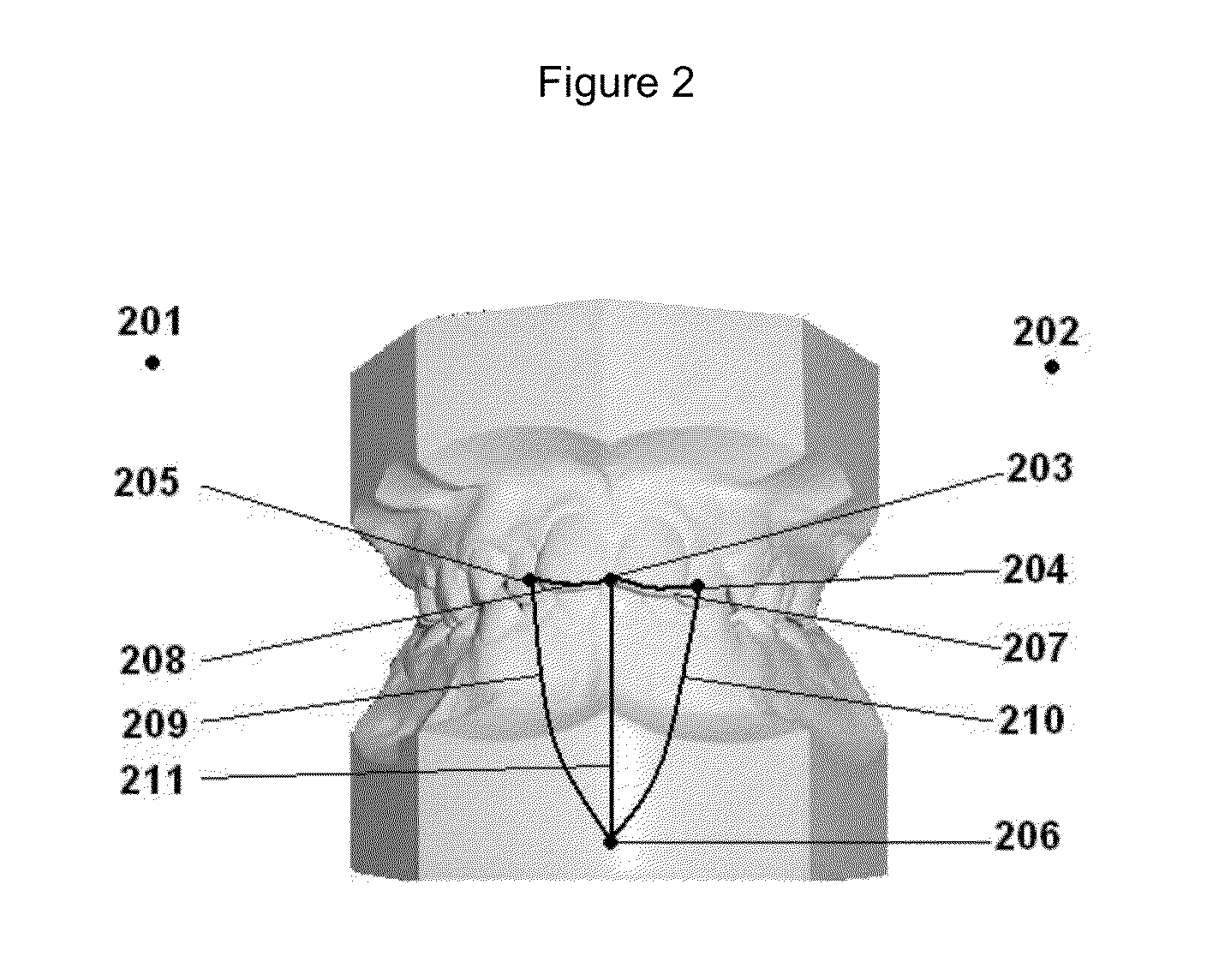

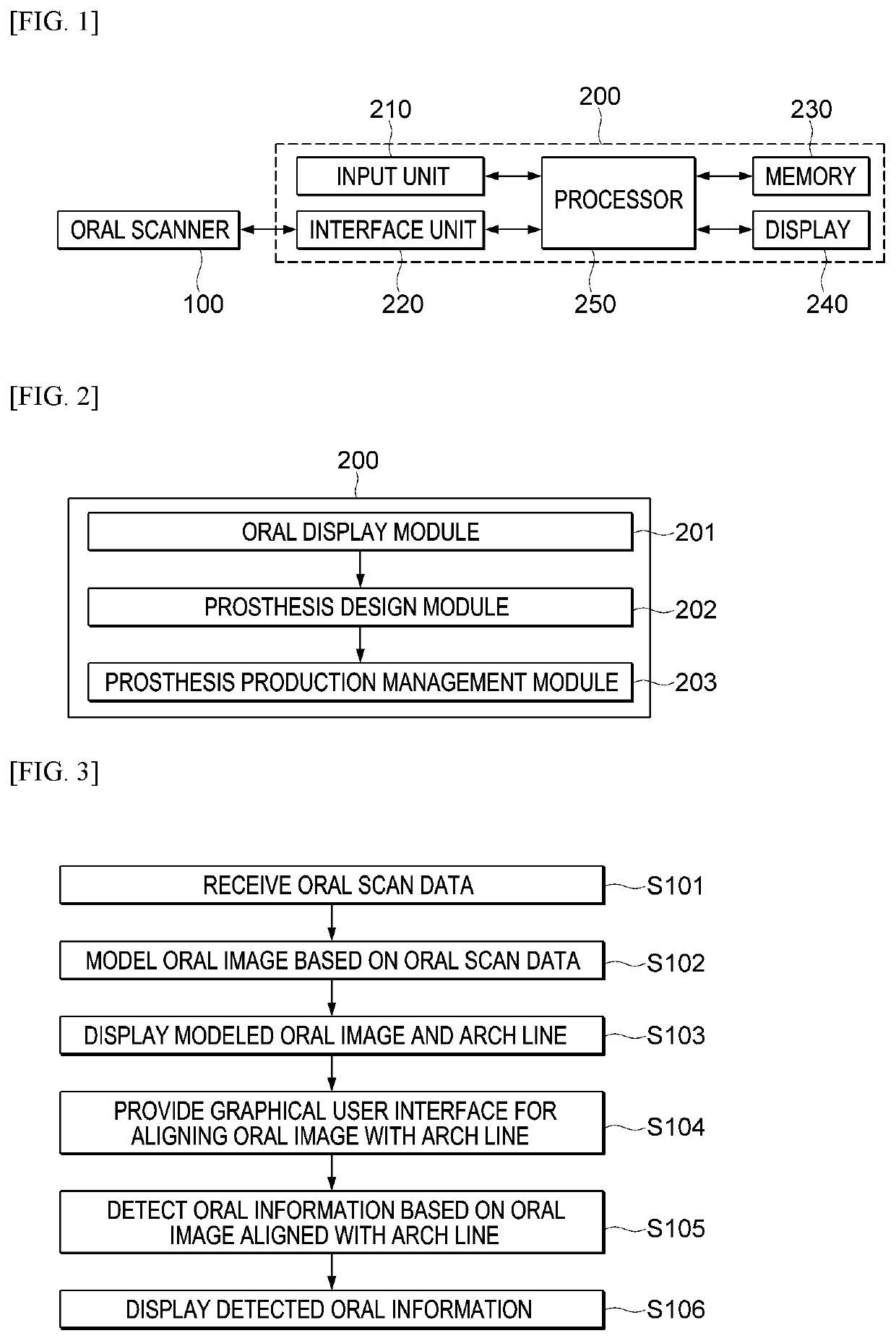

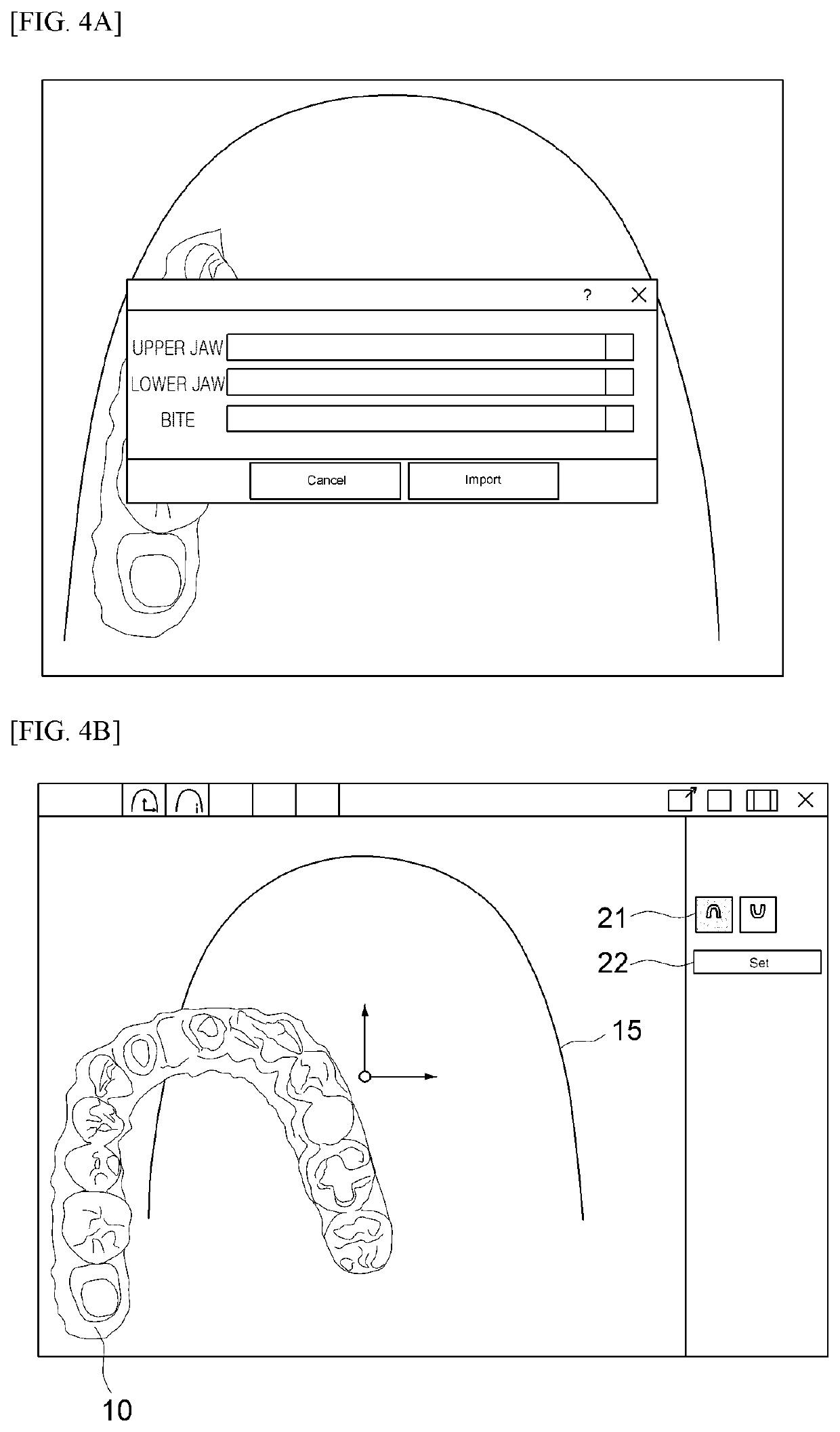

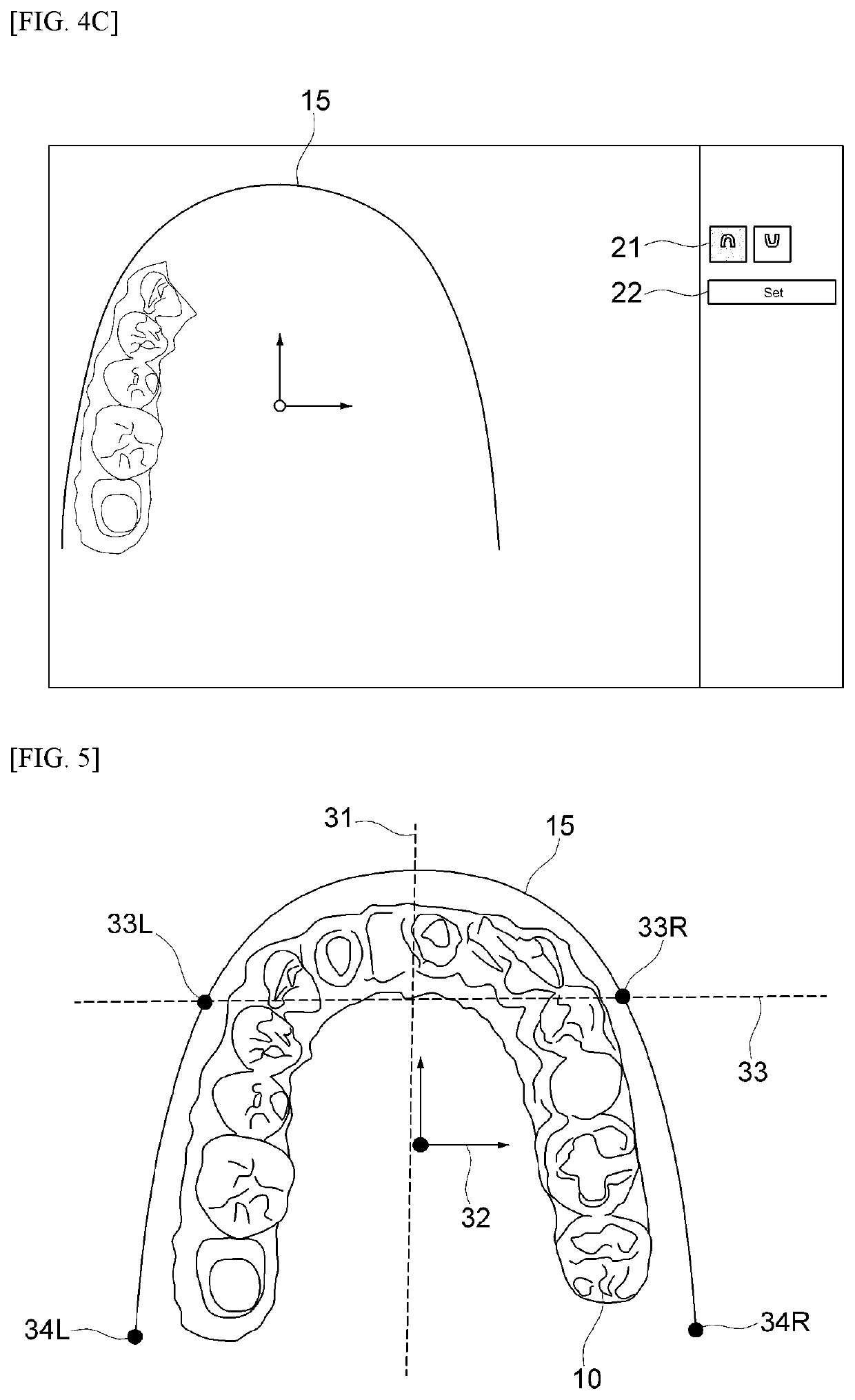

Prosthesis design method and system based on arch line

ActiveUS20200383759A1Easily and precisely designedAccurate collectionImage enhancementImage analysisData displayProsthesis

A prosthesis design method according to an embodiment includes loading 3D oral model data from a memory, displaying an oral image and an arch line of the 3D oral model data, providing an alignment interface for aligning the oral image with the arch line, and displaying the oral image aligned with the arch line.

Owner:DDS

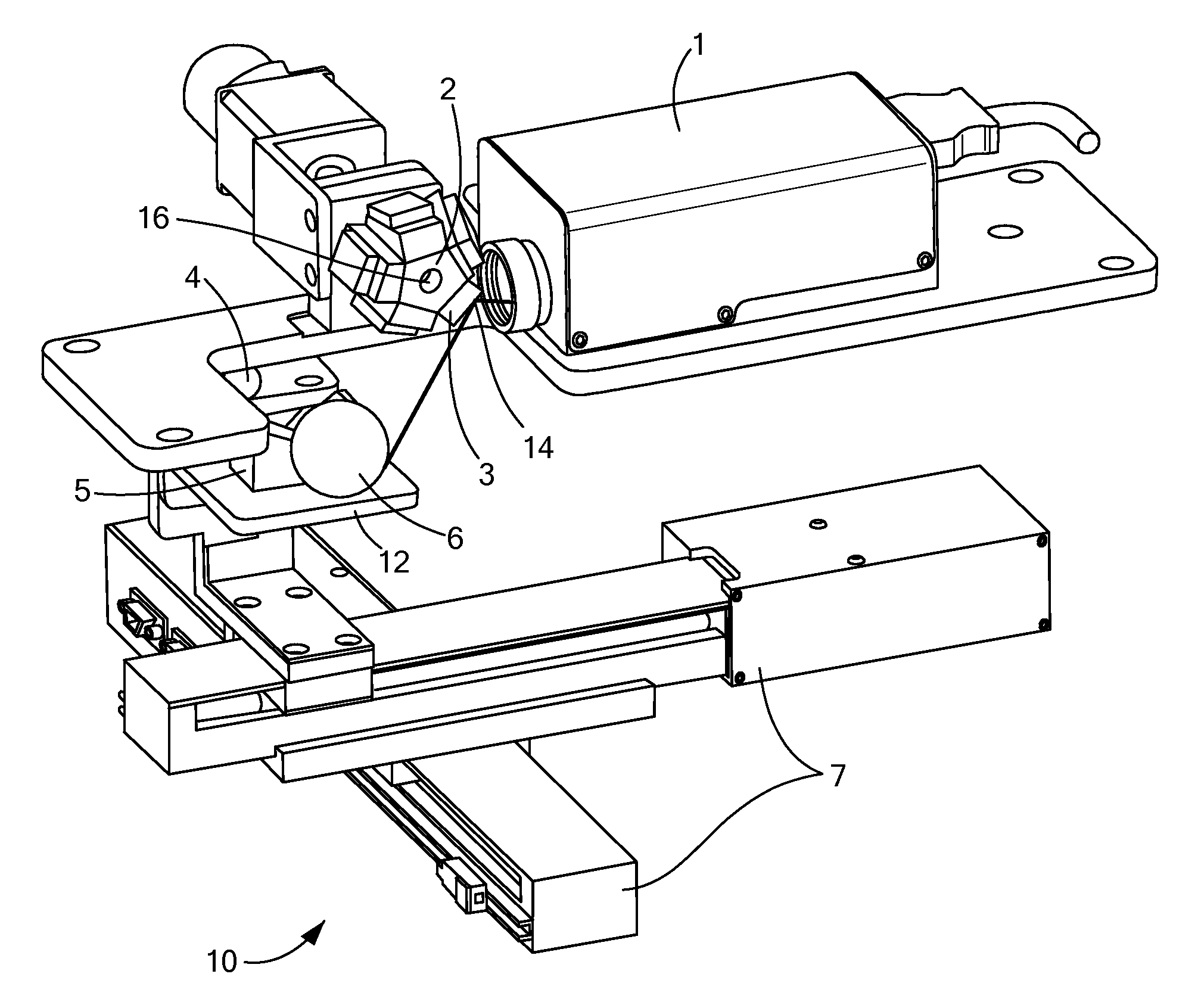

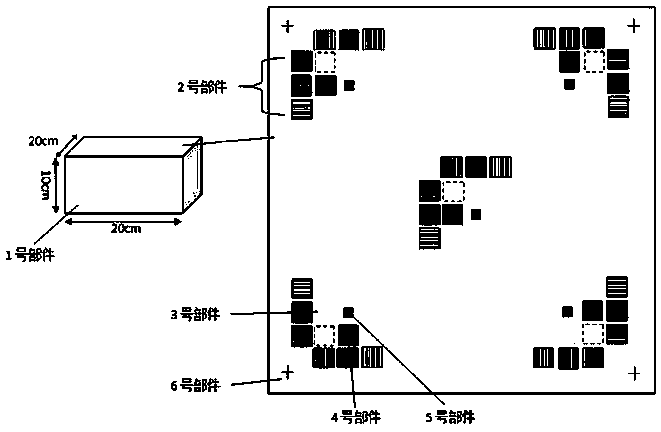

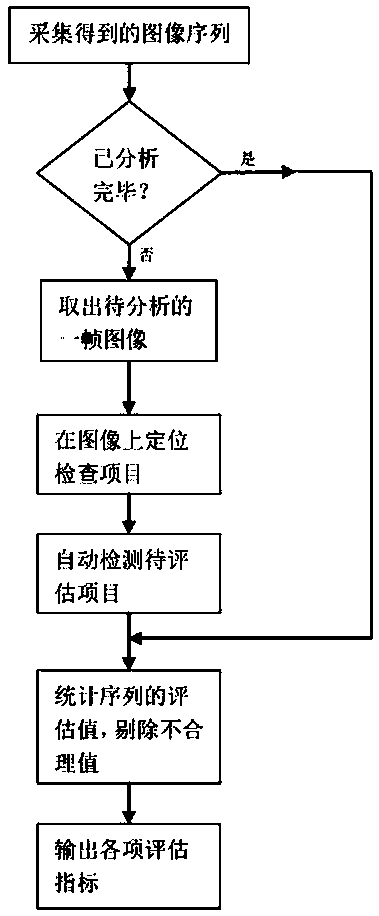

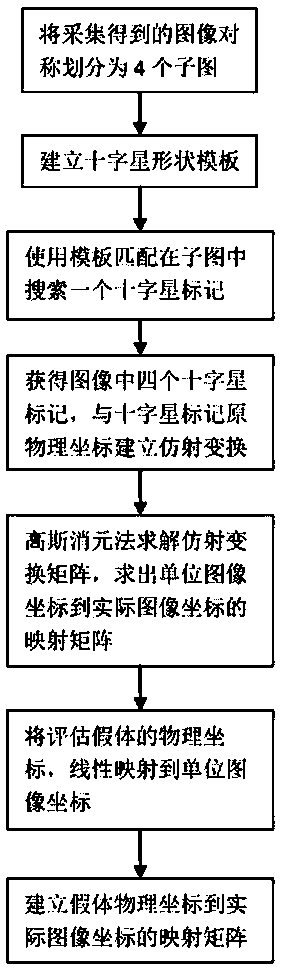

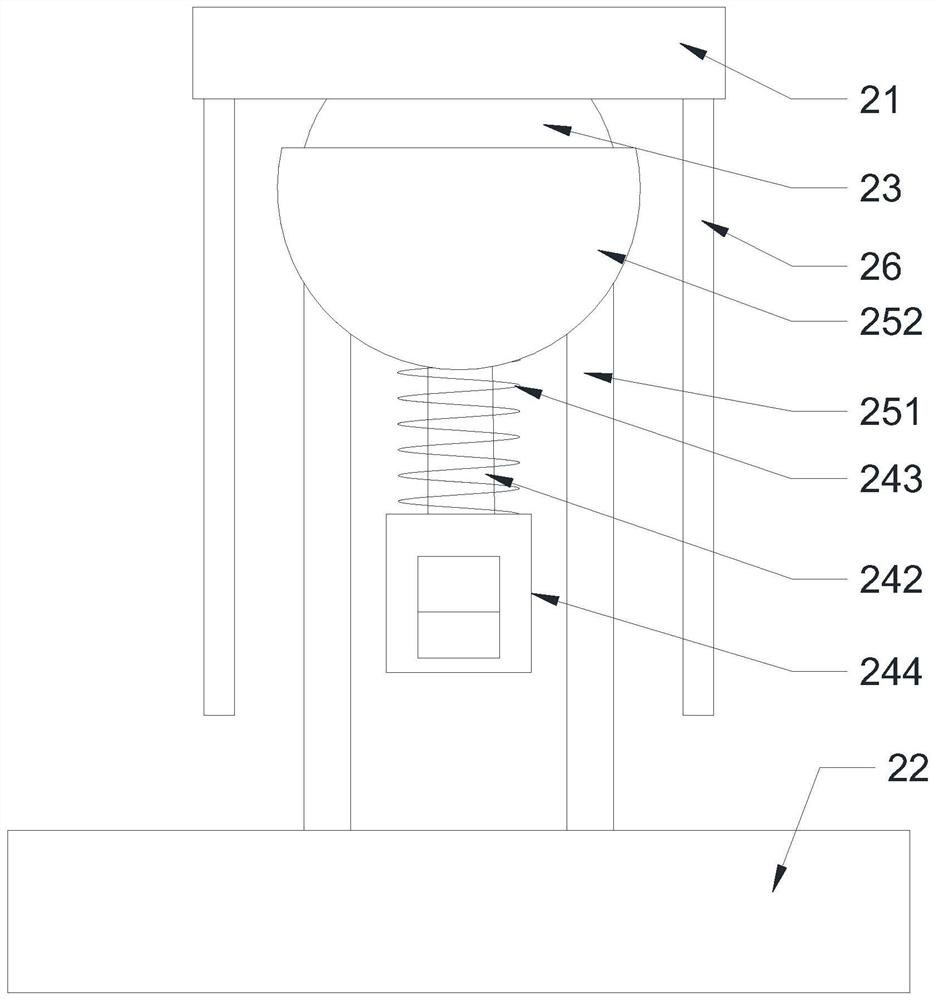

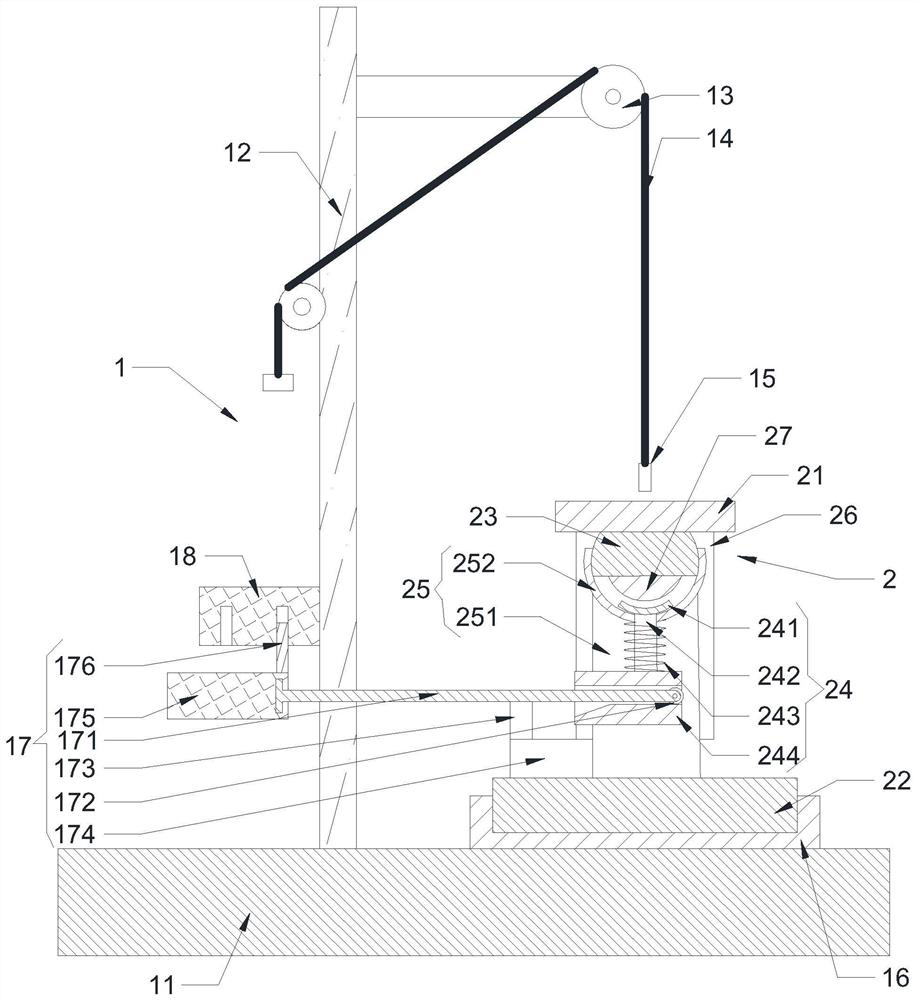

A device and method for selecting key components of digital radiological imaging equipment

Owner:HEDY MEDICAL DEVICE CO LTD

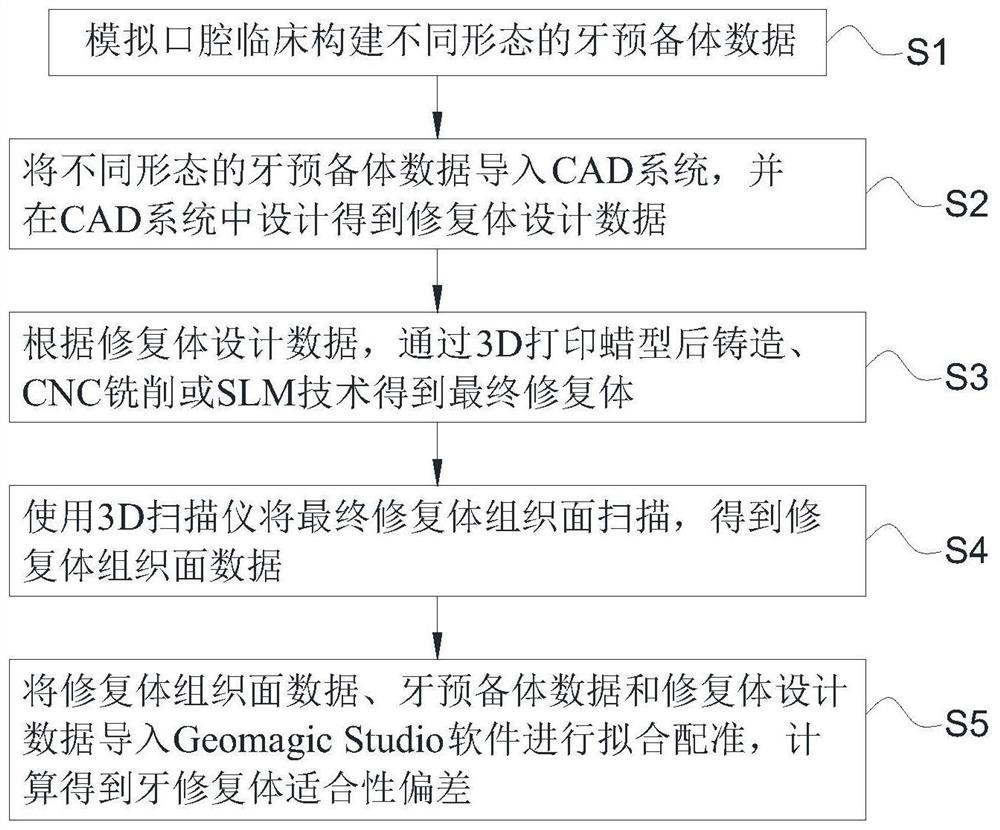

Method and system for testing suitability deviation of dental restoration CAD and manufacturing process

ActiveCN111981980AGuarantee product qualityGuaranteed production efficiencyUsing optical meansEngineeringTooth Preparations

The invention provides a method and a system for testing suitability deviation of a dental restoration CAD and a manufacturing process, and the method for testing the suitability deviation of the dental restoration CAD and the manufacturing process comprises the following steps: S1, simulating dental preparation data of different forms clinically constructed in an oral cavity; S2, importing the tooth preparation data in different forms into a CAD system, and designing in the CAD system to obtain prosthesis design data; S3, obtaining a final prosthesis through 3D printing wax pattern post-casting, CNC milling or an SLM technology according to the prosthesis design data; S4, scanning the final restoration tissue surface by using a 3D scanner to obtain restoration tissue surface data; and S5,importing the prosthesis tissue surface data, the tooth preparation body data and the prosthesis design data into Geomagic Studio software for fitting registration, and calculating to obtain the suitability deviation of the dental prosthesis. According to the method and the system for testing the suitability deviation of the dental restoration CAD and the manufacturing process, the problem that the suitability deviation of the dental restoration CAD and the manufacturing process cannot be tested in the prior art is solved.

Owner:STOMATOLOGICAL HOSPITAL OF CHONGQING MEDICAL UNIV

Cervical total spondylectomy implantable prosthesis device of 3D printing

ActiveCN108294850AGuaranteed mobilityResolve the bleedingAdditive manufacturing apparatusSpinal implantsConvex structureIn vivo

The invention discloses a cervical total spondylectomy implantable prosthesis device of 3D printing. With a cervical CT scanning sample of a patient as a template, the prosthesis device is made from medical titanium alloy by conducting three-dimensional construction and prosthesis design through 3D printing. The prosthesis device comprises an anterior device and a posterior device, wherein the anterior device comprises a C-shaped inner supporting structure, a C-shaped outer moving structure and a cross-form convex structure; and the posterior device comprises a spinous process simulation fixing device and four medical cervical screws. According to the prosthesis device provided by the invention, via the anterior device, an axial supporting effect is achieved between upper and lower adjacent vertebral bodies, and the anterior device can be stably kept on a fixed position and can show relatively strong activity in overall torsion and lateral curvature motions of cervical vertebra; and via the posterior device, upper and lower spinous processes of the cervical vertebra and related parts can be fixed, so that four fixed surfaces are accurately located on a transverse process via the screws, and an excised cervical vacancy space is supplemented; therefore, discomfort of an in-vivo or external form can be relieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Patient-specific bone fracture prostheses and methods of making the same

The invention concerns a method for manufacturing a prosthesis (11) for a fractured long bone of a patient, the method comprising the steps of: A) providing data representative of the fractured long bone, the fractured long bone comprising a diaphyseal fragment (2) comprising a medullary cavity (8); B) based on said data, designing the prosthesis specifically to the patient, the prosthesis comprising a stem part (12) configured to be inserted into the medullary cavity, step B) comprising: a sub-step of choosing, specifically to the patient, a contact zone (40) of the medullary cavity onto which a respective chosen mechanical stress is planned to be applied by the stem part, and a sub-step of designing the stem part so that the stem part may be inserted into the medullary cavity and thus apply the chosen mechanical stress to said contact zone; and C) manufacturing the prosthesis designed at step B).

Owner:HOWMEDICA OSTEONICS CORP

Design method of a patella prosthesis

ActiveCN109833121BSoft tissue preservationExtended service lifeJoint implantsComputer aided designPatella prosthesisTibia

Owner:重庆熙科医疗科技有限公司

3D-printed cervical total spondylectomy implantable prosthetic device

ActiveCN108294850BGuaranteed mobilityResolve the bleedingAdditive manufacturing apparatusSpinal implantsConvex structureIn vivo

The invention discloses a cervical total spondylectomy implantable prosthesis device of 3D printing. With a cervical CT scanning sample of a patient as a template, the prosthesis device is made from medical titanium alloy by conducting three-dimensional construction and prosthesis design through 3D printing. The prosthesis device comprises an anterior device and a posterior device, wherein the anterior device comprises a C-shaped inner supporting structure, a C-shaped outer moving structure and a cross-form convex structure; and the posterior device comprises a spinous process simulation fixing device and four medical cervical screws. According to the prosthesis device provided by the invention, via the anterior device, an axial supporting effect is achieved between upper and lower adjacent vertebral bodies, and the anterior device can be stably kept on a fixed position and can show relatively strong activity in overall torsion and lateral curvature motions of cervical vertebra; and via the posterior device, upper and lower spinous processes of the cervical vertebra and related parts can be fixed, so that four fixed surfaces are accurately located on a transverse process via the screws, and an excised cervical vacancy space is supplemented; therefore, discomfort of an in-vivo or external form can be relieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com