Individualized design and manufacturing system and method for full knee joint replacing prosthesis

A total knee replacement and manufacturing system technology, applied in the field of personalized design and manufacturing systems, can solve the problems of inability to realize the personalized design and manufacture of knee prosthesis, and achieve the goal of getting rid of the knee joint structure that cannot be well matched and optimizing the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

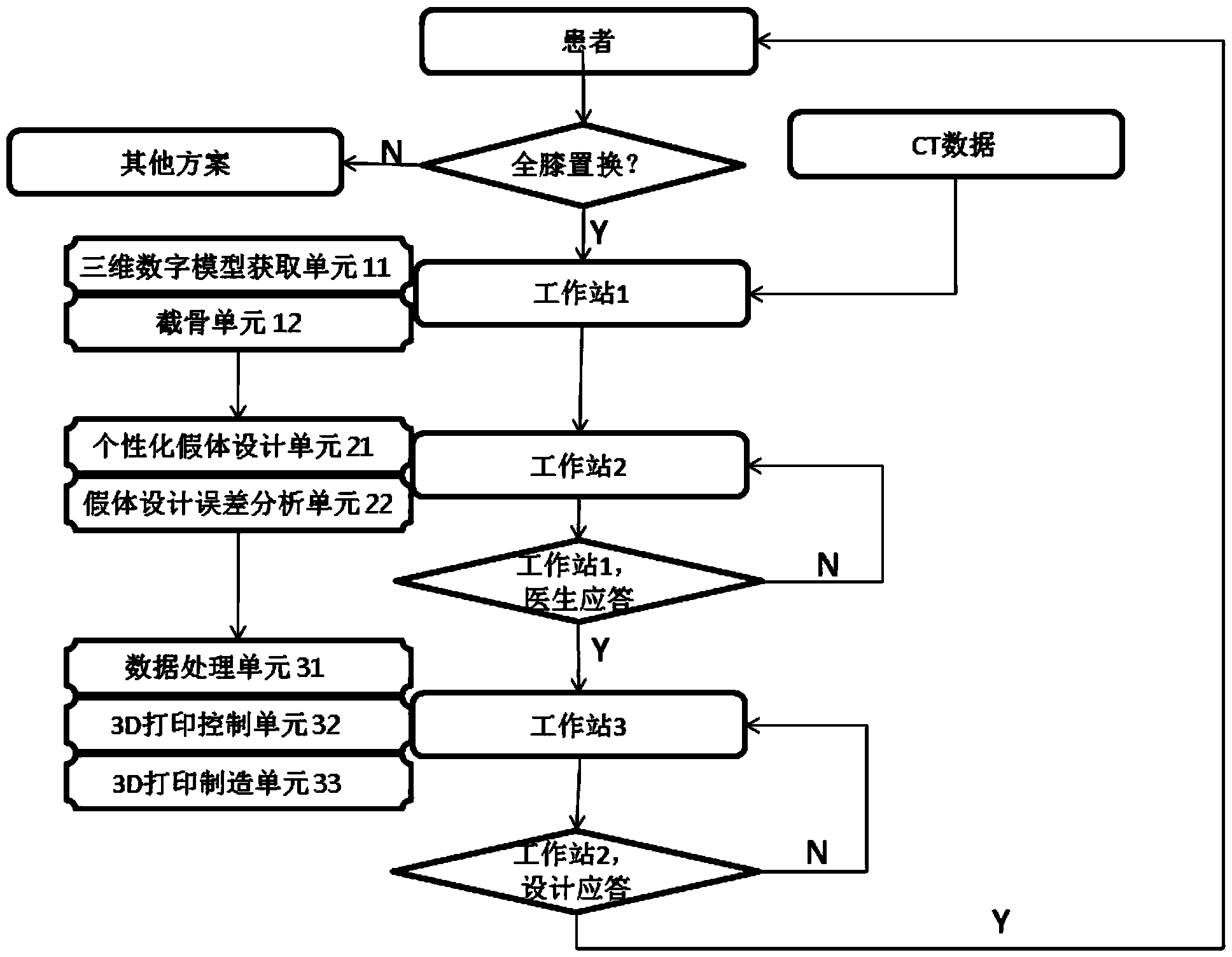

[0041] Such as figure 1 As shown, the personalized design and manufacturing system of the total knee replacement prosthesis of the present invention includes three workstations set up in different places, which are respectively digitized knee joint CT / MRI data acquisition and doctor's surgery planning workstation 1, and personalized parameter analysis and setting And personalized TKA (total knee replacement) prosthesis design and virtual verification workstation 2, and 3D printing direct manufacturing data processing and control workstation 3, the information exchange between the three workstations is realized through the Internet network.

[0042] Wherein, digital knee joint CT / MRI data acquisition and doctor's surgery planning workstation 1 includes a three-dimensional digital model acquisition unit 11 and an osteotomy unit 12:

[0043](1) The thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com