Design method of personalized condylar prosthesis with topological optimized fixing unit and porous condylar head unit, and personalized condylar prosthesis

A fixed unit, topology optimization technology, applied in prosthesis, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing stress shielding, not fully considering biological and biomechanical factors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings.

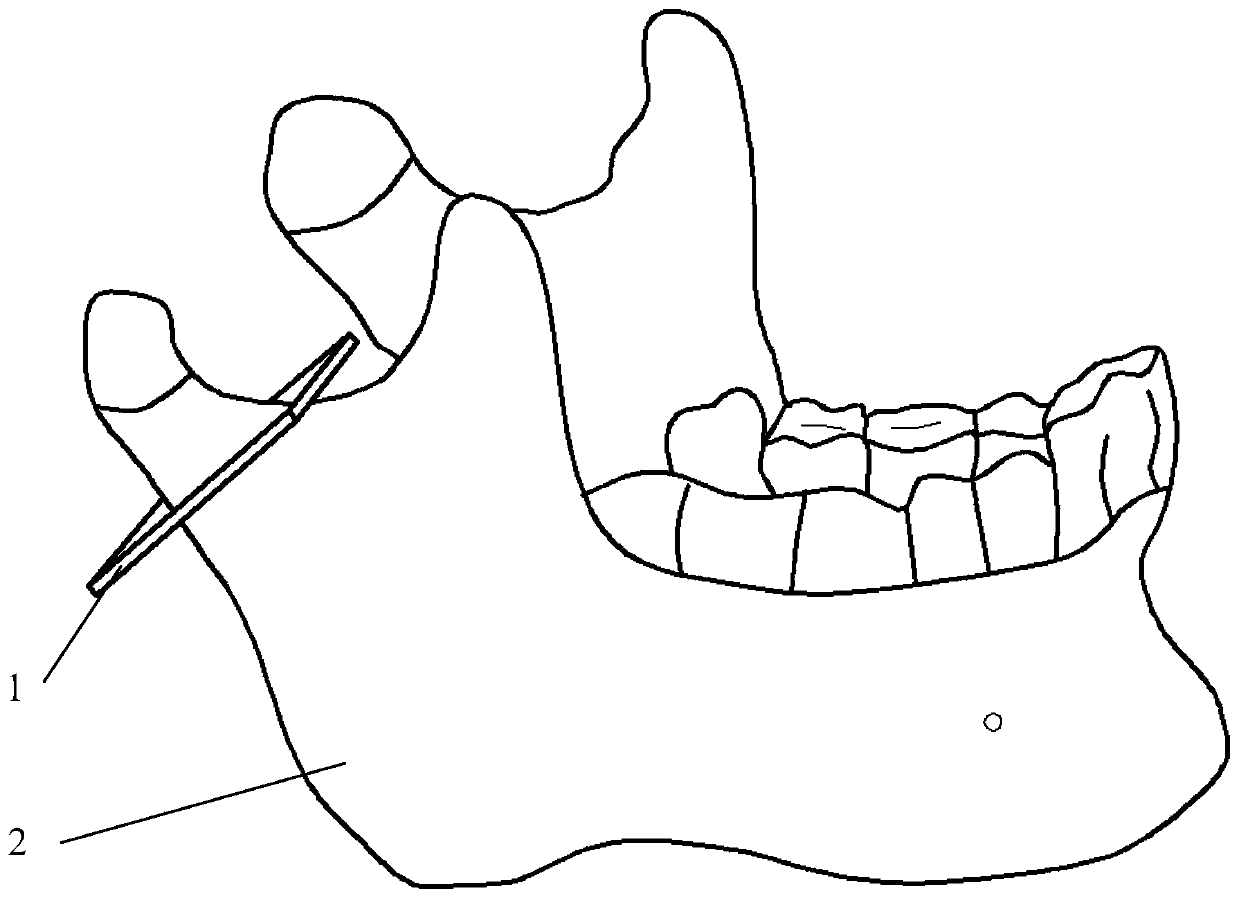

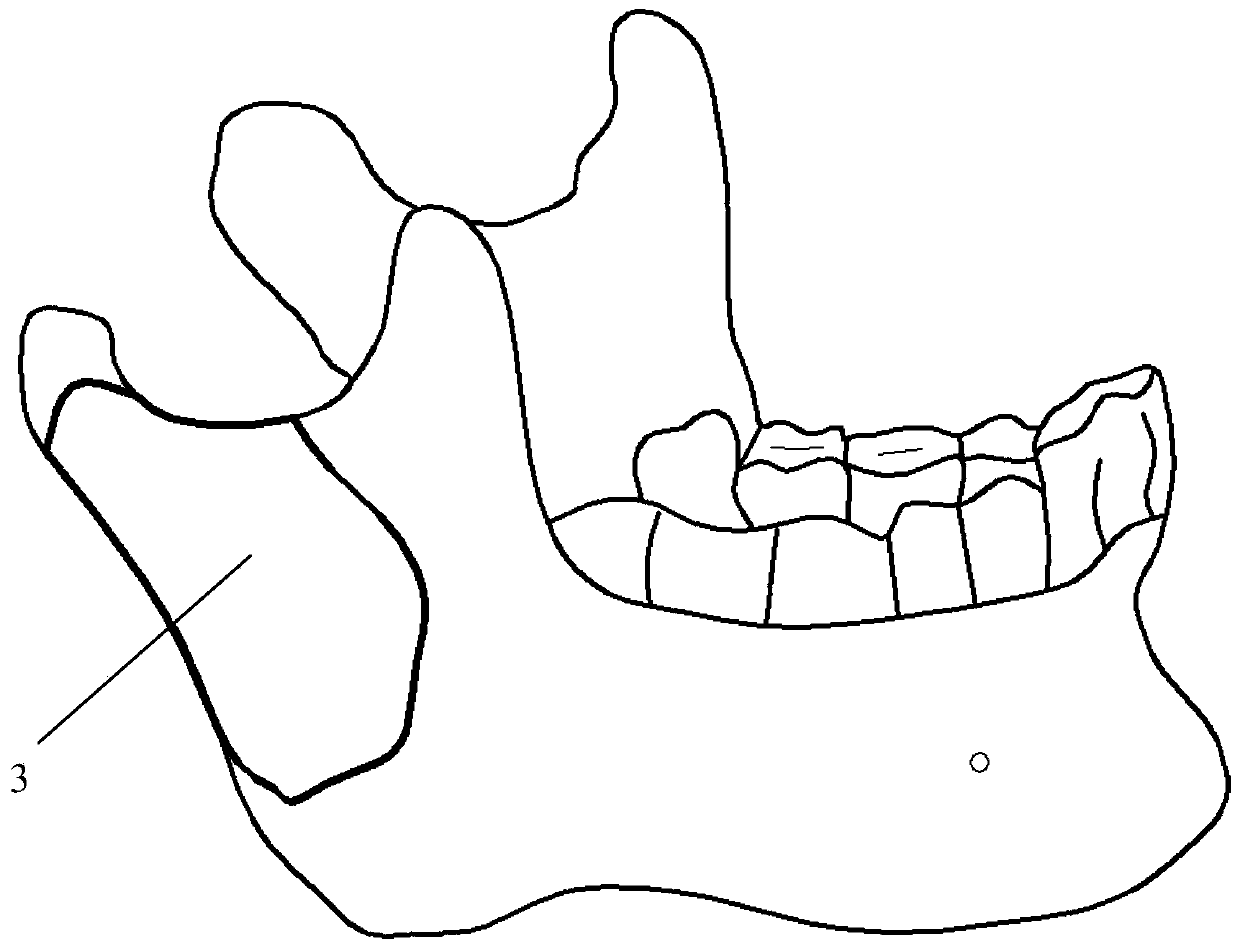

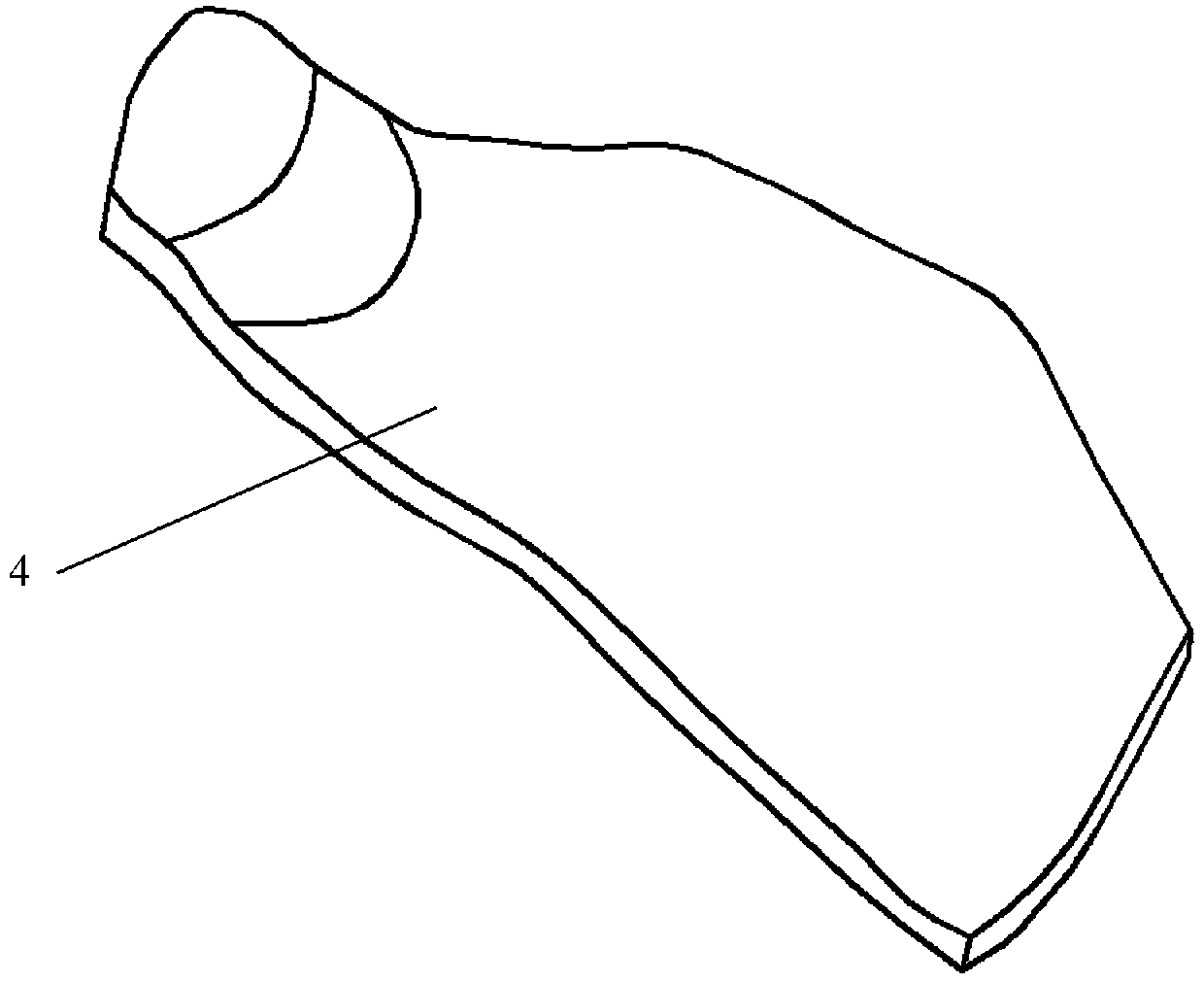

[0058] refer to Figure 1 to Figure 13 , a method for designing a personalized condylar prosthesis with a topology-optimized fixation unit and a porous condylar head unit, comprising the following steps:

[0059] 1.) Condylar prosthesis reconstruction and mandibular biomechanical model construction

[0060] 1.1) Carry out computed tomography scan to the temporomandibular joint patient, obtain its CT data, utilize medical image processing software such as Mimics, carry out medical image processing and model reconstruction, obtain the mandibular three-dimensional surface model (hollow stl format), condyle shape if Basically complete and direct reconstruction, or if one side is healthy, it can be generated by a mirror image, or if it is unhealthy, you can redesign an artificial condyle shape according to the shape of the glenoid fossa, the shape of the mandible, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com