Method for optimally selecting thighbone prostheses based on material performance multi-objective optimization

A multi-objective optimization, femoral prosthesis technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as no solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

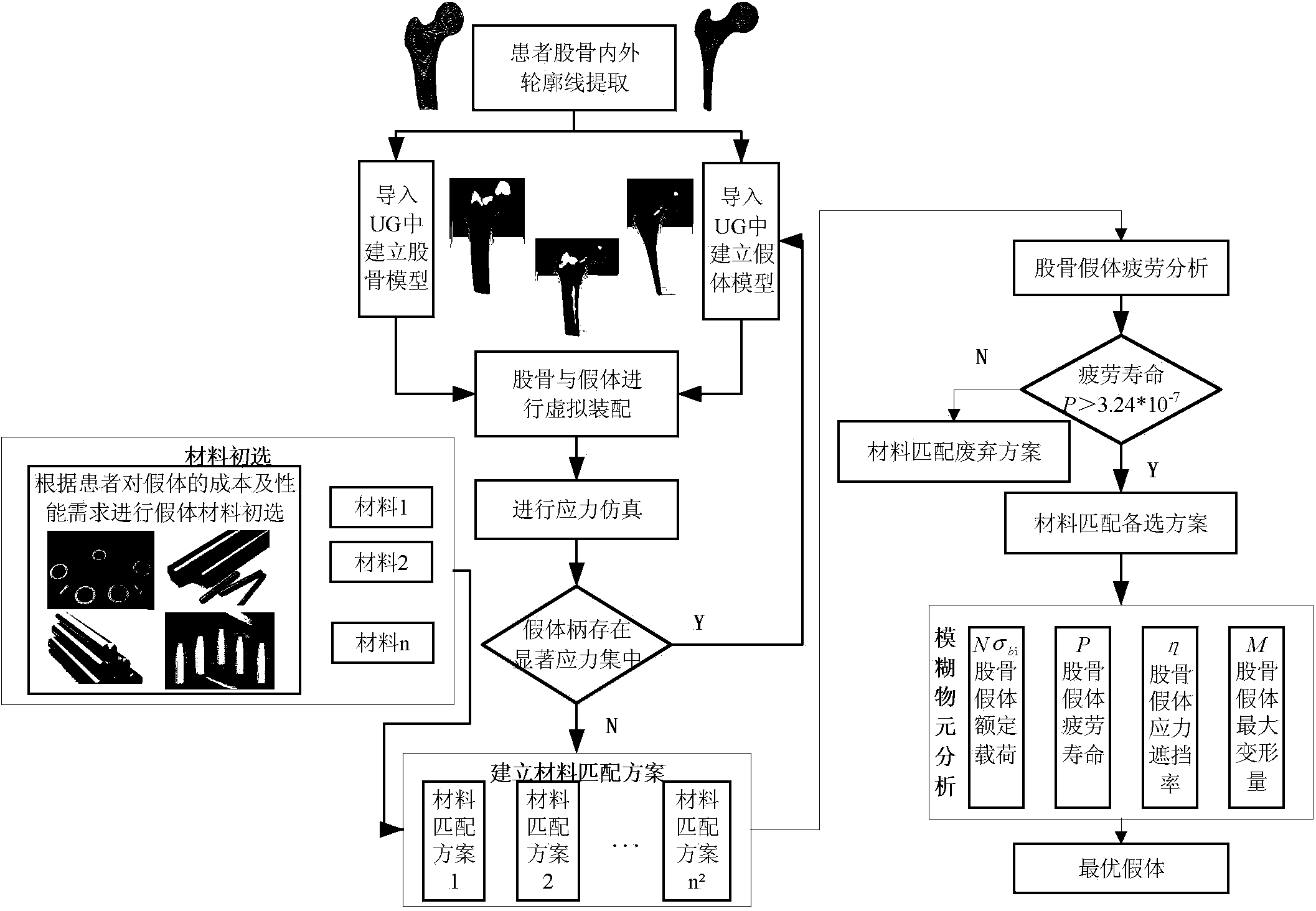

Method used

Image

Examples

Embodiment

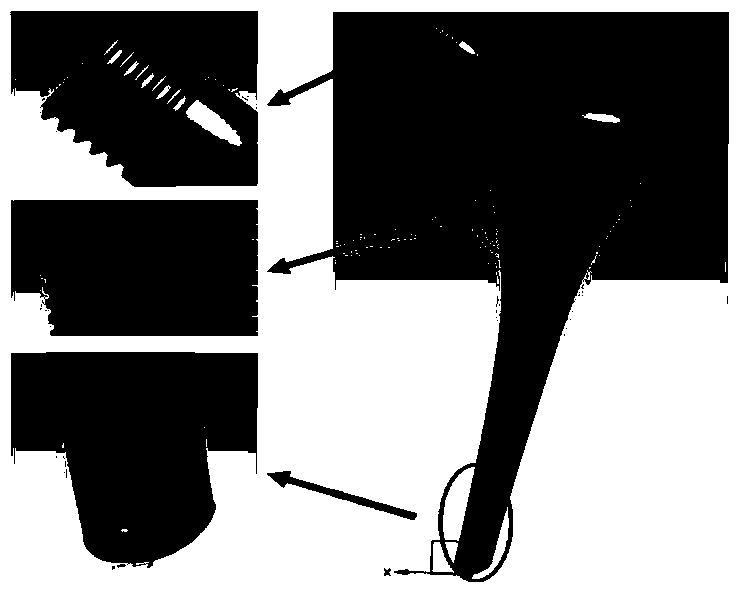

[0106] 1. Optimizing the mechanical simulation of the ball head structure

[0107] Using zirconium-niobium alloy as the femoral prosthesis material, the mechanical simulation of the spherical head, ellipsoidal head, and cockle wire spherical head was carried out respectively. Figure 5 is the deformation distribution when the acetabular model is matched with three different shapes of femoral heads. When the spherical femoral head acts on the acetabular model, the maximum deformation of the acetabulum occurs at the center, and the deformation decreases with the increase of the radius, and the maximum deformation is 0.037435mm; the ellipsoidal femoral head acts on the acetabular model , the maximum deformation also occurs at the center of the sphere, and the maximum deformation is 0.024877mm; the cockle-line spherical femoral head is different, and the maximum deformation of the acetabular model occurs at the position away from the center of the sphere, indicating that the cockl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com