pneumatic tire

A technology of pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, tire parts, tire edges, etc., which can solve the problems of easy increase of tire displacement and peeling, and achieve the effect of improving high-speed durability and suppressing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

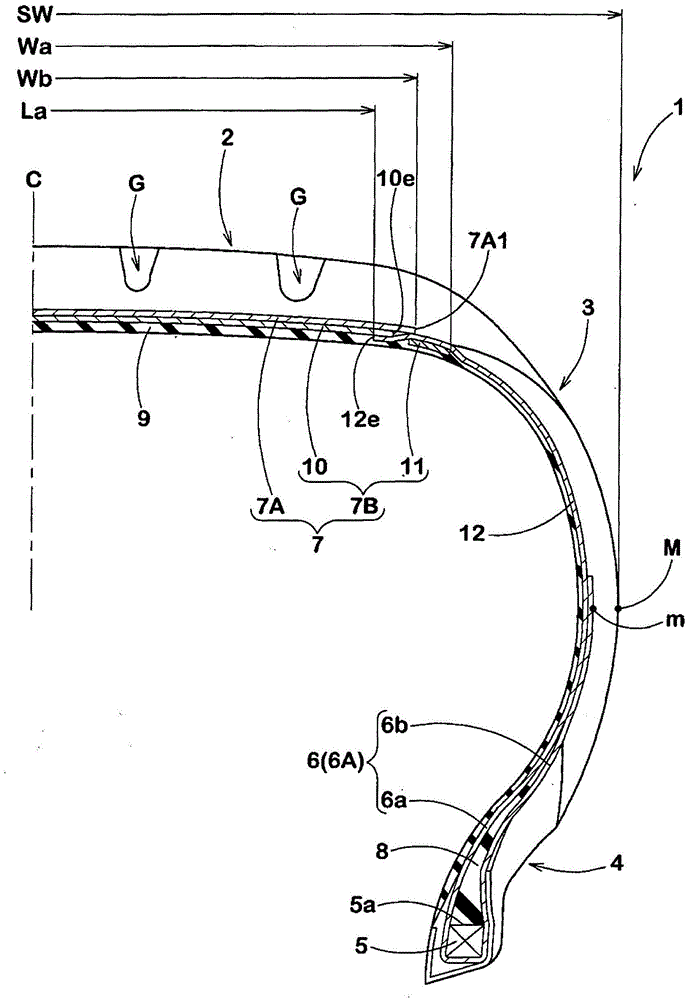

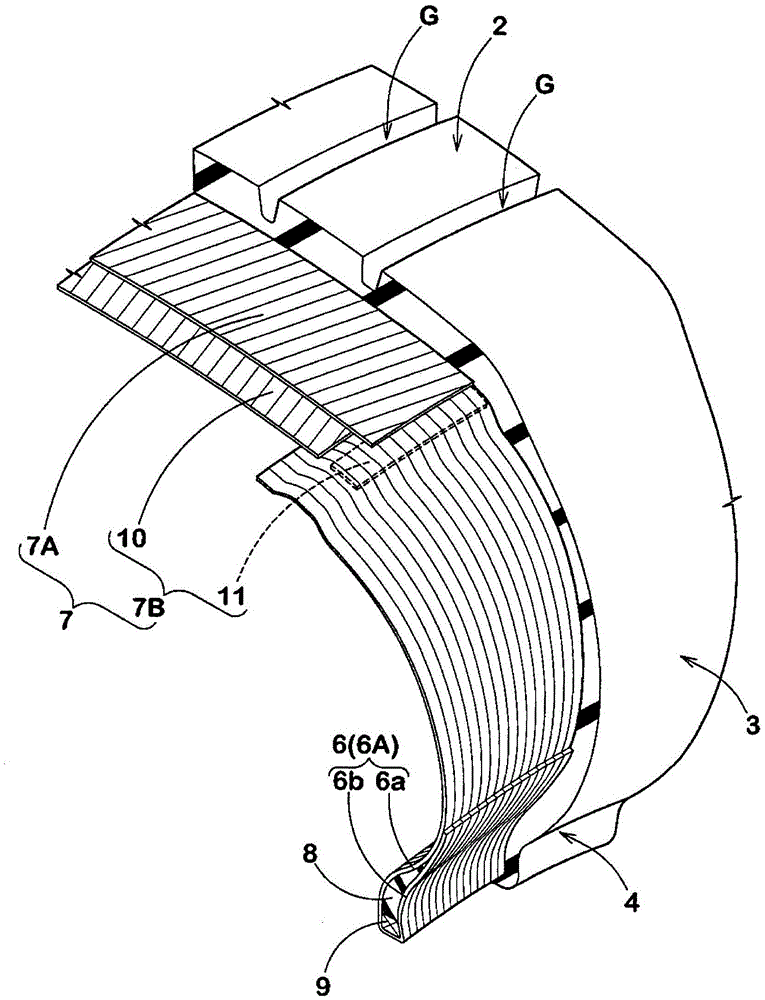

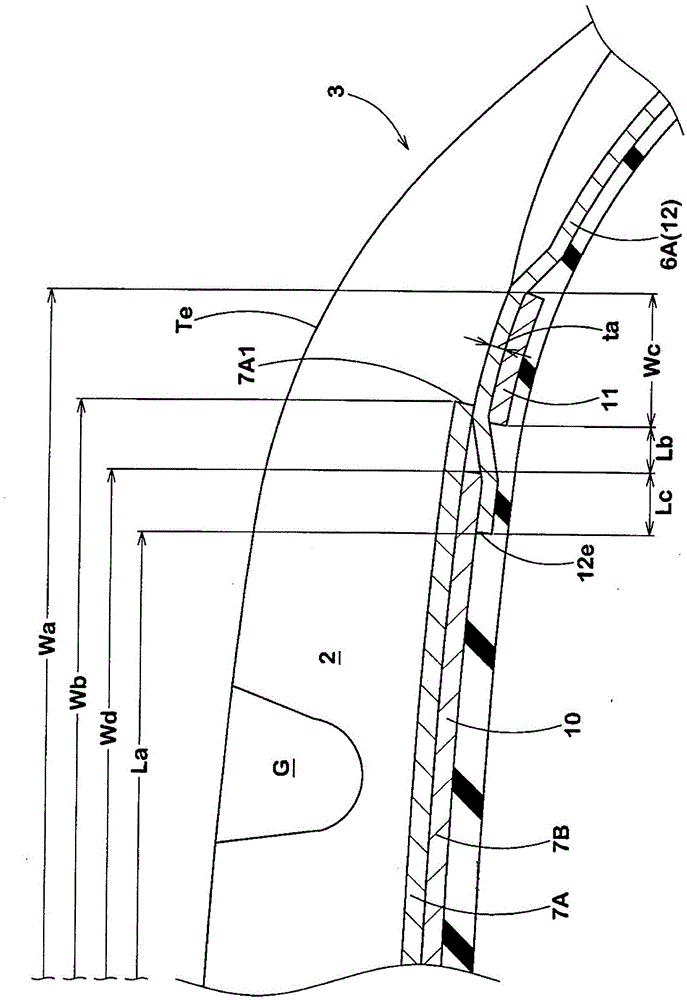

[0039] In order to confirm the effect of the present invention, based on the specifications of Table 1, a product formed as figure 1 The basic structure shown, and the tire size is 195 / 65R15 passenger car tires, and various tests were carried out on it. In addition, the main specifications other than Table 1 are the same.

[0040] The test method is as follows.

[0041]

[0042] The mass of each tire was measured and expressed using an index with the reciprocal of Comparative Example 1 being 100. The higher the value, the better.

[0043]

[0044] Using a drum testing machine, assemble the rim of the test tire on a rim of 17×7JJ, and make 20 test tires with a diameter of 1.7m under the conditions of filling an internal pressure of 220kPa, a load of 4.5kN, and a speed of 60km / h. The tires were driven on the drum and the time to damage was measured for each tire. The results are represented by an index with the average value of the damage time in Comparative Example 1 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com