Radial tire with dual-cavity sidewall structure

A technology for radial tires and sidewalls, which is applied in the field of radial tires, can solve problems such as the increase in tire market claims rate, the impact on enterprise development, and the decline in high-speed performance, so as to improve the anti-puncture function, improve driving comfort, and improve high-speed durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

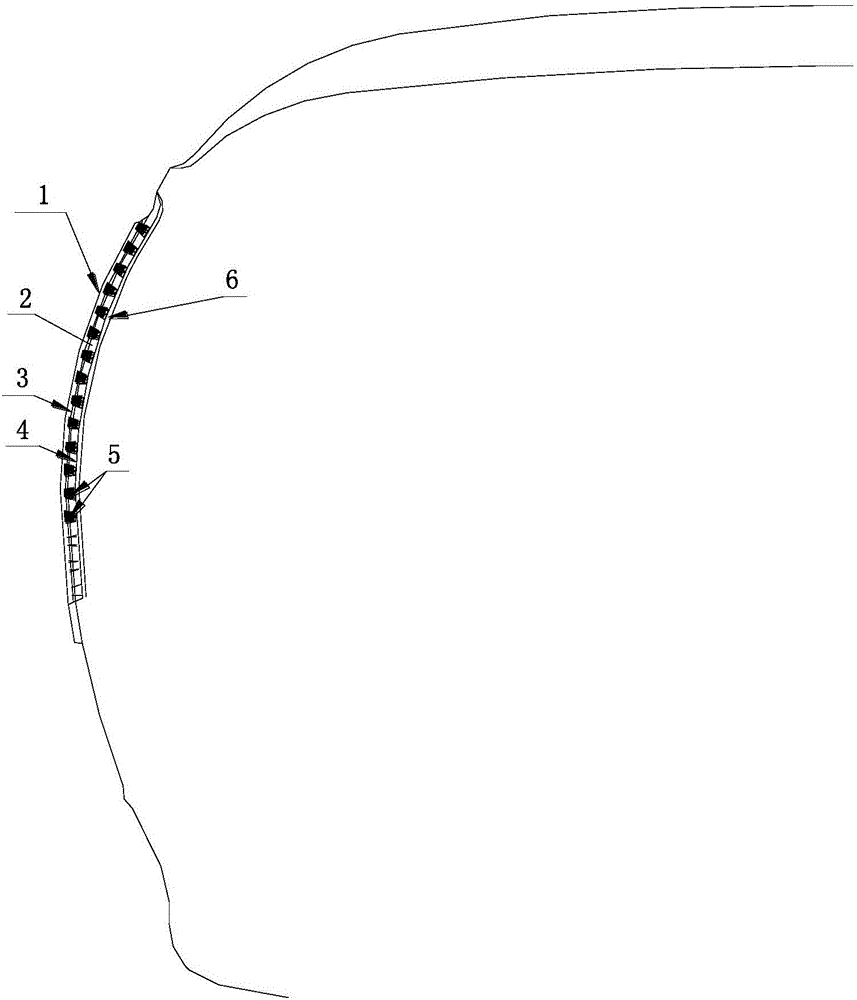

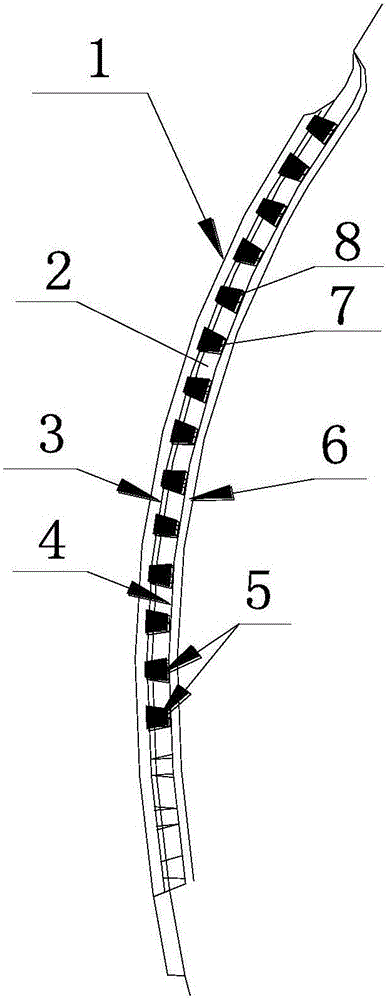

[0016] Such as figure 1 and figure 2 As shown, the sidewall portion of the radial tire with a dual-chamber sidewall structure according to the present invention includes an outer sidewall 1 and an inner sidewall 6, the inner sidewall 6 is located on the inner side of the outer sidewall 1, the outer sidewall 1 and the inner sidewall There is a closed hollow cavity 2 between the sidewalls 6, that is, the present invention adds a cavity 2 to the original sidewall part, so that the tire has an outer sidewall 1 and an inner sidewall 6. After the cavity 2 is added, there are two sidewalls on the sidewall of the tire, namely the outer sidewall 3 and the inner sidewall 4. When the tire is hit or punctured during driving, only the outer sidewall 3 is damaged, ensuring Ensure that the inner sidewall 4 is not damaged or slightly damaged, which ensures the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com