Pneumatic tire

A pneumatic tire, tire circumferential technology, applied to the reinforcement layer of pneumatic tires, tire parts, transportation and packaging, etc., can solve the problems of reduced elastic modulus, reduced handling stability, etc., to prevent lowering and ensure stable handling performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

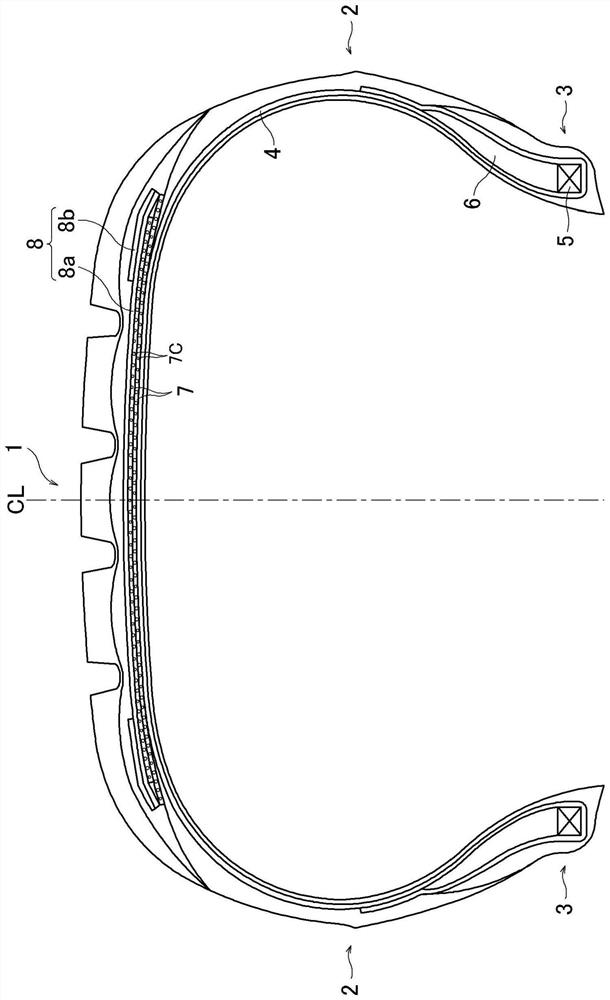

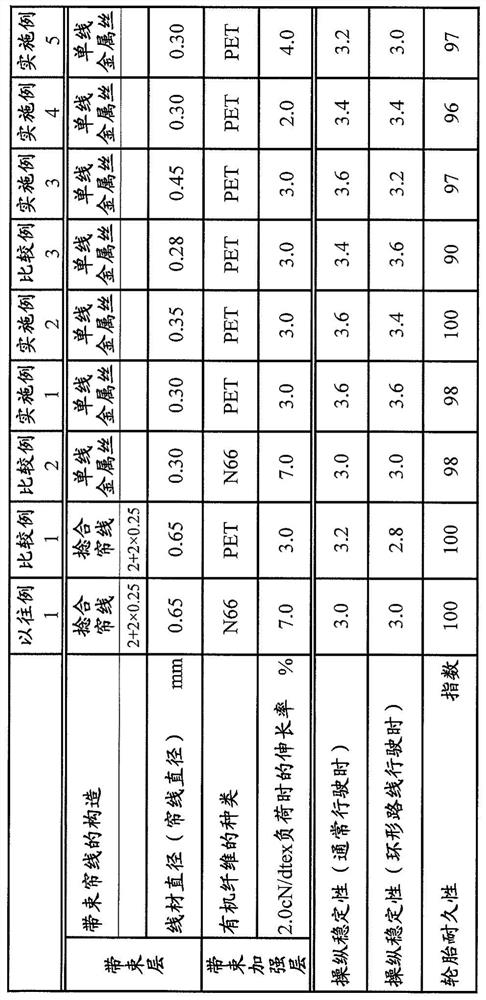

[0032] Made a tire size 235 / 40R18 with figure 1 The basic structure is illustrated and the structure of the steel cord constituting the belt layer, the wire diameter (cord diameter) and the type of organic fiber used for the organic fiber cord constituting the belt reinforcement layer, and 2.0 of the organic fiber cord Tires of Conventional Example 1, Comparative Examples 1 to 3, and Examples 1 to 5 having different elongation at cN / dtex load as shown in Table 1.

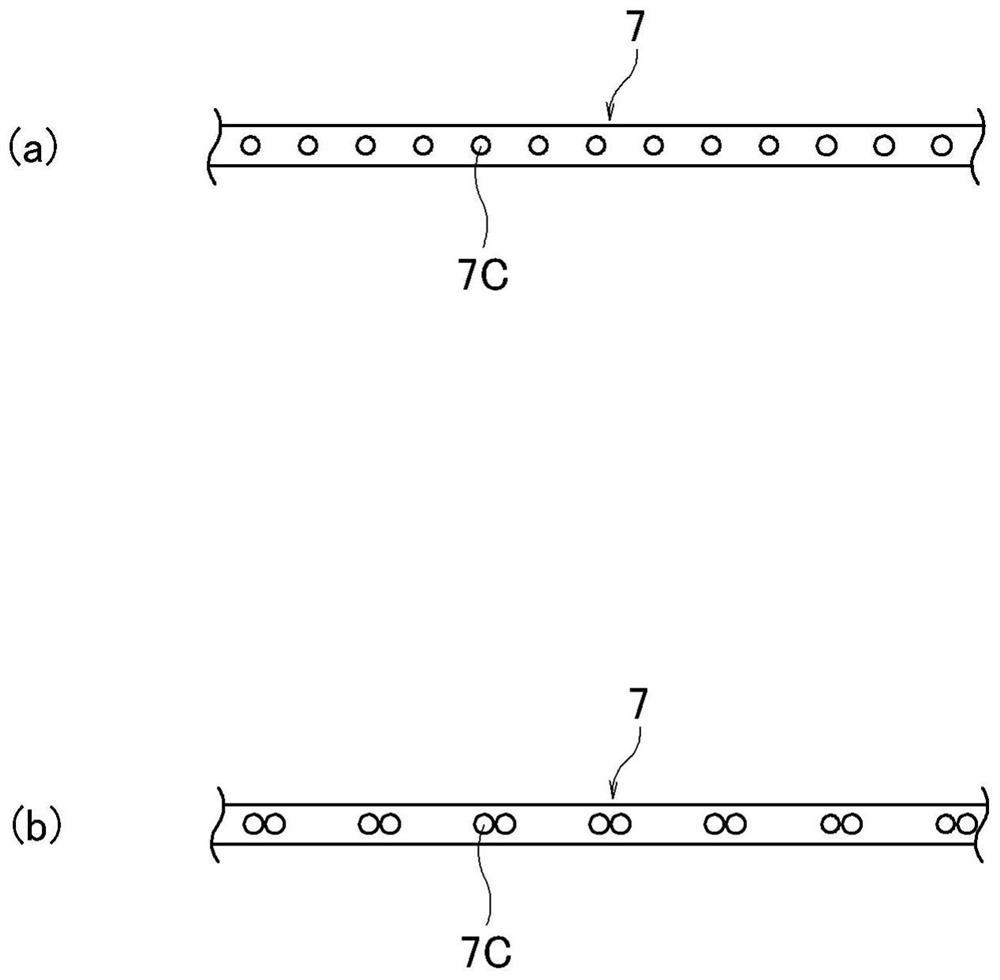

[0033] In either case, the belt reinforcement layer has a belt formed by aligning one organic fiber cord (nylon 66 fiber cord or PET fiber cord) and covering it with a covering rubber, and is wound spirally in the tire circumferential direction. Wrapped seamless construction. The cord implantation density in the tape was 50 cords / 50mm. In addition, the organic fiber cord (nylon 66 fiber cord or PET fiber cord) had a structure of 1400 dtex / 2 in Conventional Example 1 and Comparative Example 2, and had a structure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com