Large-span flat top plate installation structure of railway vehicle

A rail vehicle and installation structure technology, applied in the direction of railway roofs, etc., can solve the problems of simple installation, unsightly, inconvenient maintenance and replacement of flat roofs, etc., and achieve the effect of simple assembly, easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

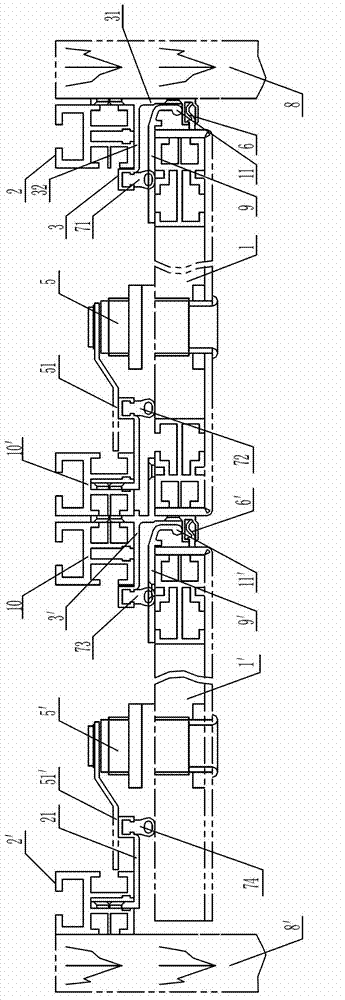

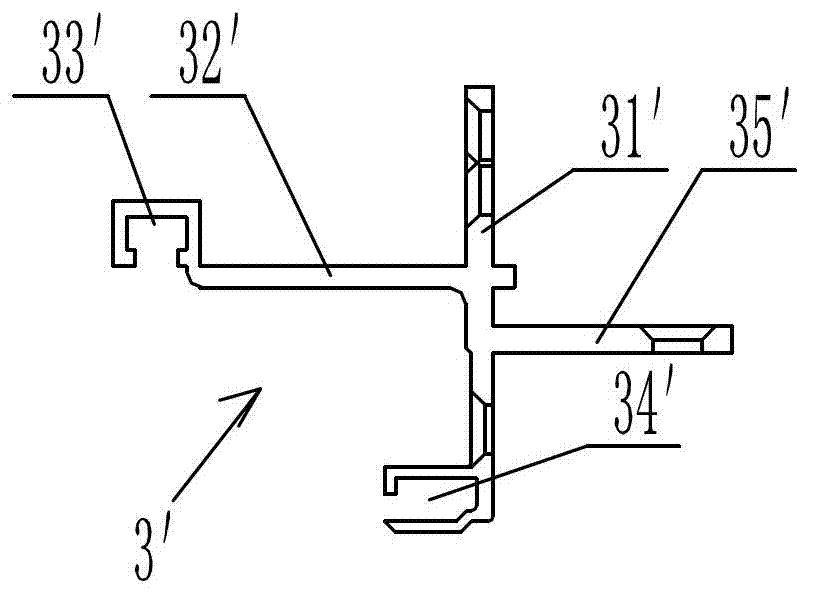

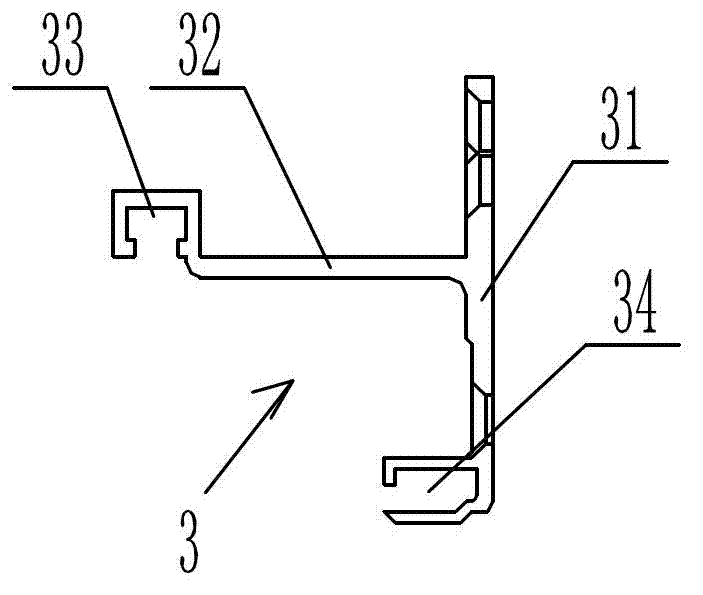

[0019] Such as figure 1 As shown, the rail vehicle large-span flat roof installation structure of this embodiment consists of: a beam (not shown in the figure), four flat roof skeletons installed below the beam and arranged in parallel, and the first flat roof hoisted below the flat roof skeleton 1. The second flat roof 1', the first and second flat roof frames 2, 2' are located on the outside and fixed to the first and second partition walls 8, 8' of the vehicle respectively, the third and fourth flat roof frames 10 ’, 10 are located in the central position, the third and fourth flat roof frames 10’, 10 are fixed together by the first connecting piece 3’, the first connecting piece 3’ has a first vertical plate and a A first plate 32' and a second plate 35' extending vertically to both sides of a vertical plate. The outer end of the first flat roof 1 is fixed to the first flat roof skeleton 2 through the second connecting piece 3. The second connecting piece 3 has a second v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com