Two stage rotary compressor

A two-stage compressor, rotary technology, applied in the direction of rotary piston machinery, rotary piston pump, rotary piston/oscillating piston pump components, etc., can solve the problem of reduced compression efficiency, reduced bearing reliability, deflection To prevent problems such as increased pressure, to prevent the reduction of operating efficiency, reduce the loss of overcompression, and suppress the effect of pressure pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

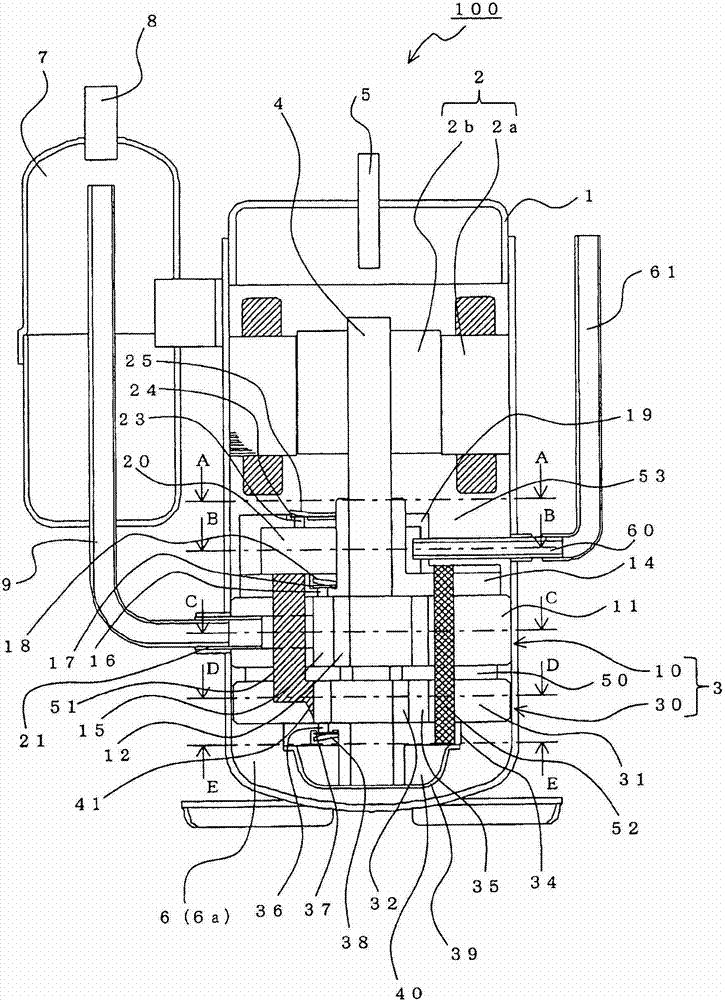

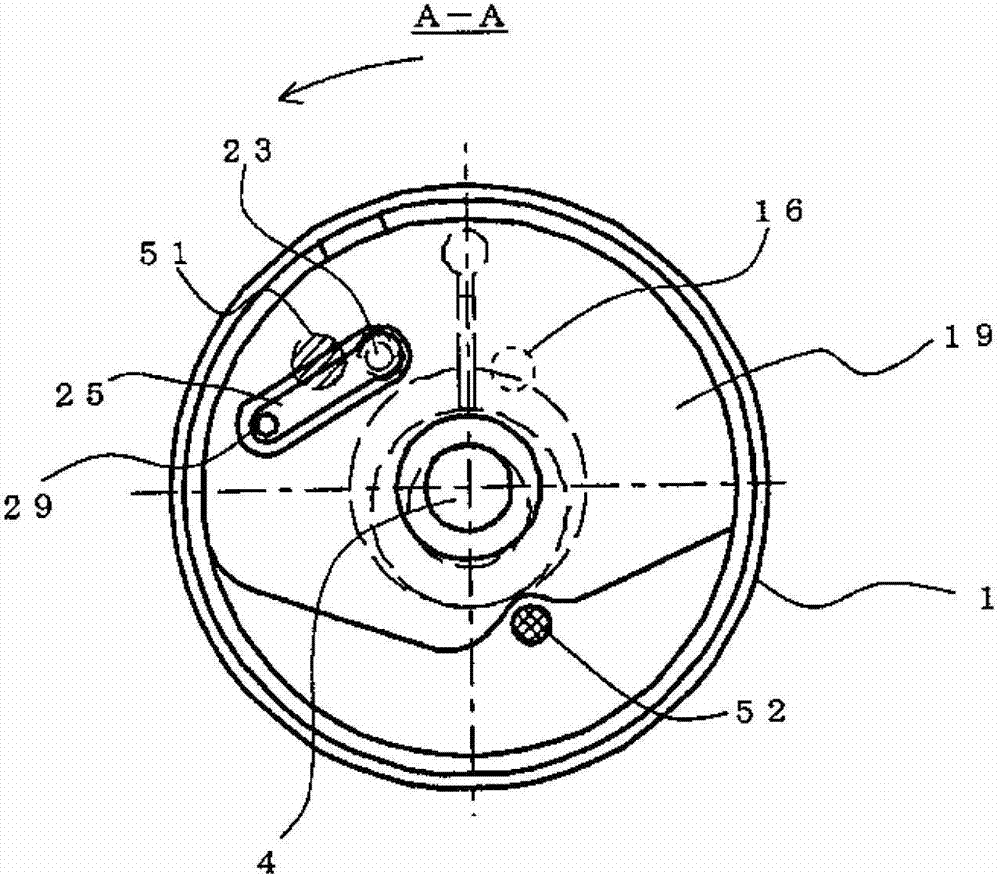

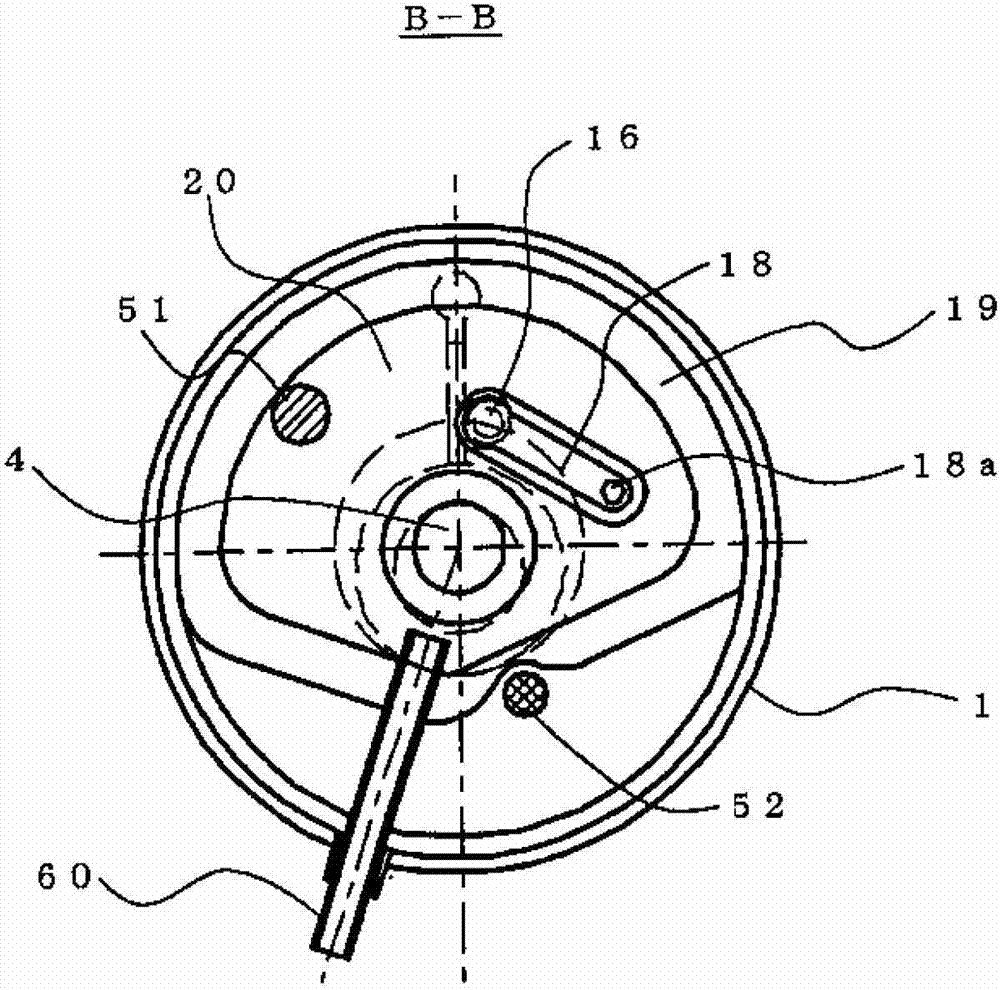

[0029] Hereinafter, the configuration of an example (two-stage compressor 100 ) of the rotary two-stage compressor of the present invention will be described.

[0030] figure 1 It is a vertical cross-sectional view showing a two-stage compressor according to an embodiment of the present invention. in addition, figure 2 express figure 1 A-A sectional view of, image 3 express figure 1 The B-B sectional view, Figure 4 express figure 1 C-C cutaway view, Figure 5 express figure 1 D-D cutaway view, Figure 6 express figure 1 E-E cutaway view. in addition, figure 1 It is a diagram combining longitudinal sections cut at a plurality of cut positions for easy understanding of the structure of the two-stage compressor 100 . Therefore, the correct position of each structure observed from the top view or bottom view is Figure 2 ~ Figure 6 location shown.

[0031] In the two-stage compressor 100 of the present embodiment, two compression units (the low-stage compression u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com