Contact measuring head for measuring thickness of surface mount technology (SMT) screen plate

A contact-type, thickness-measuring technology, applied in the field of measuring tools, can solve the problems of reduced measurement accuracy, high price, measurement accuracy and stability that cannot meet the requirements of SMT stencil thickness measurement accuracy of 1um, etc., to reduce the cost of the probe, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

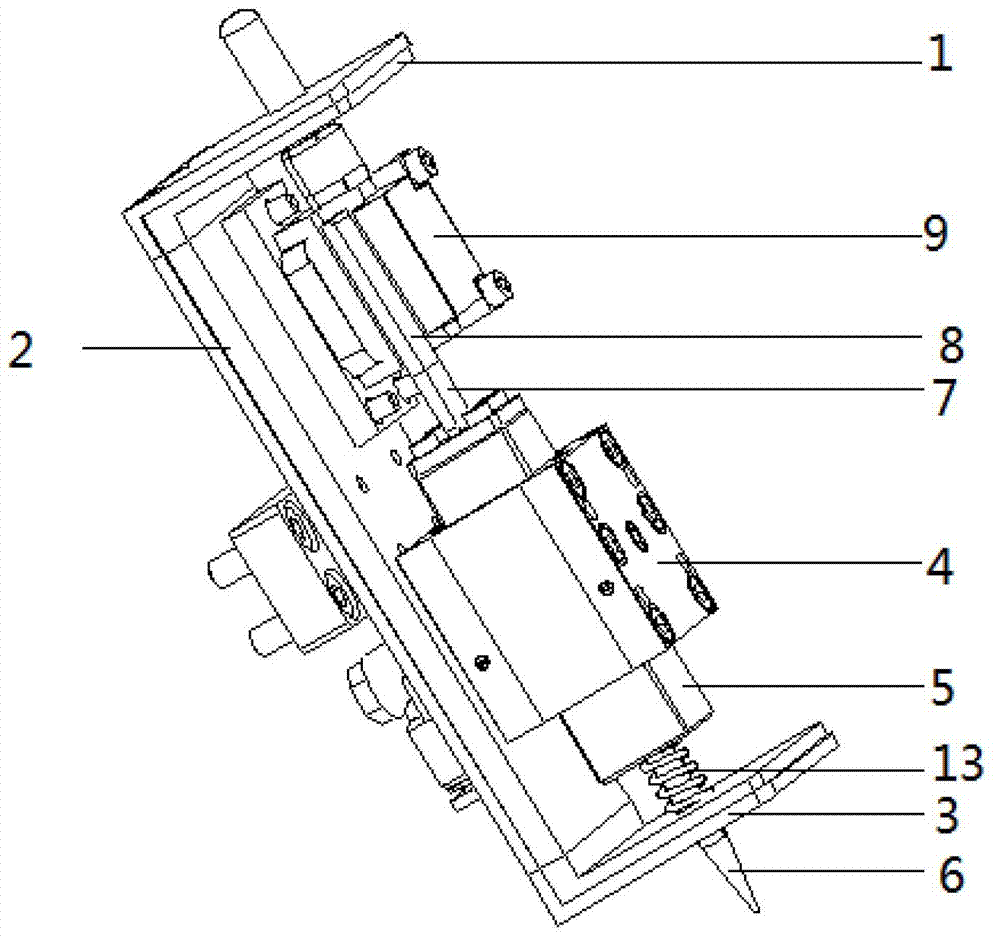

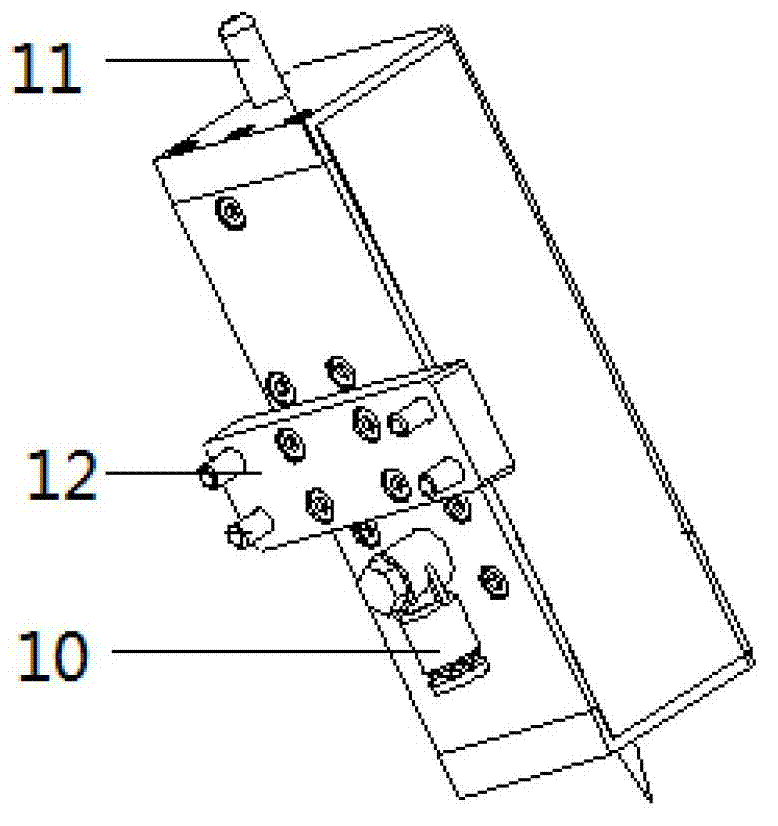

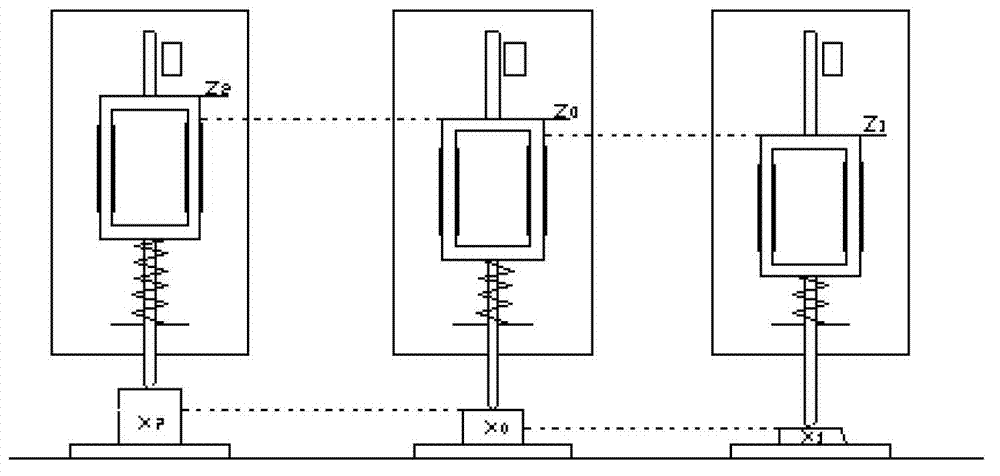

[0022] like Figure 1 to Figure 3 As shown, the technical solution of the present invention is: a contact measuring head for SMT stencil thickness measurement, including a housing, an air rail, a probe 6, a connector 7, a high-resolution laser ruler 8, and a displacement sensor 9 , a trachea joint 10 and a data cable 11;

[0023] Wherein, the housing is composed of a top cover 1, an installation cover 2 and a bottom cover 3, and the top and bottom ends of the installation cover 2 are vertically installed with the top cover 1 and the bottom cover 3 respectively, on the top cover 1 and the bottom cover 3 Both have through holes;

[0024] The air guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com