Workplace occupational exposure simulation analysis method based on computational fluid dynamics (CFD) technology

A workplace simulation analysis technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of single toxic gas leakage scene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] This CFD-based workplace occupational exposure simulation analysis technology is mainly used in occupational exposure assessment in occupational disease hazard assessment of construction projects, quantitative analysis and practical application of hazardous substance exposure assessment.

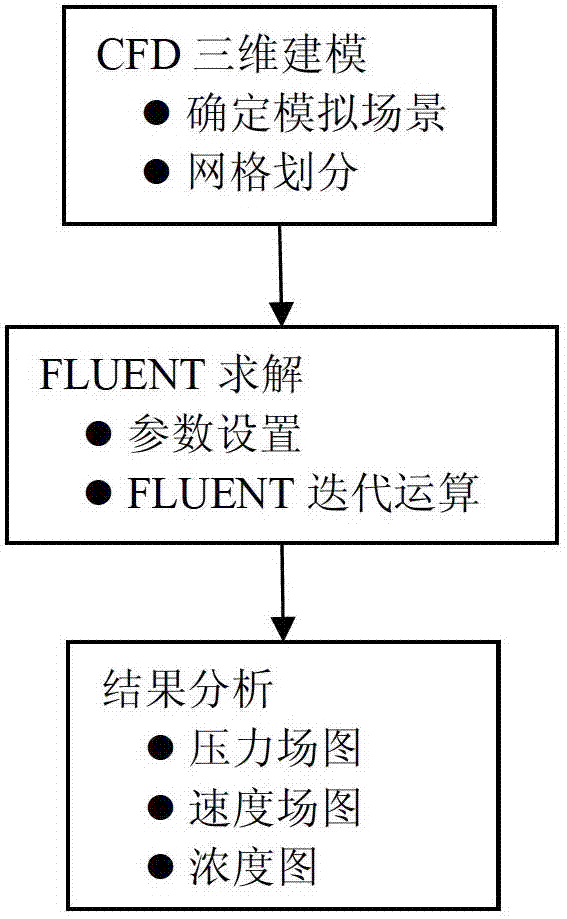

[0031] The technical content and method implementation steps of CFD-based simulation analysis of occupational exposure in the workplace are shown in the appendix figure 1 .

[0032] Case Analysis of Occupational Exposure Simulation in Workplace Based on CFD Technology

[0033] 1. CFD three-dimensional modeling

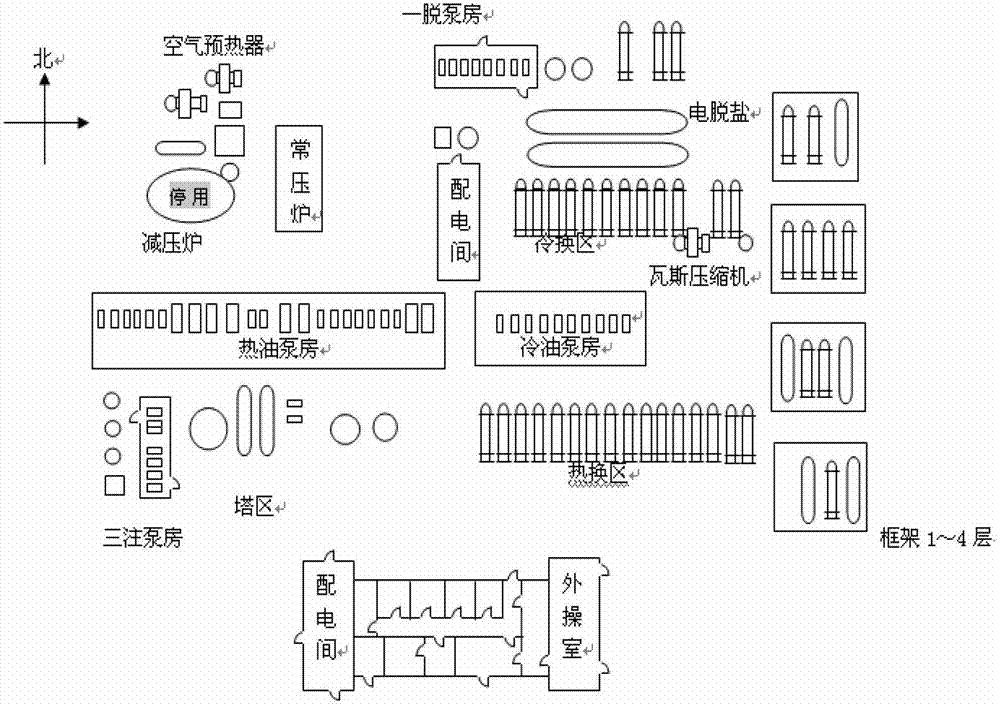

[0034] (1) Determine the simulation scene

[0035] The crude oil processing capacity of the atmospheric and vacuum distillation unit of a petrochemical enterprise is 1.3 million tons per year, and the annual processing hours are 8,400 hours. It mainly produces ethylene materials, reformed materials, jet fuel fractions, diesel fractions and atmospheric heavy oil. The atmosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com