Low smoke non-halogen flame retardant thermoplastic elastomer composite material and preparation method thereof

A thermoplastic elastomer and composite material technology, which is applied in the field of low-smoke halogen-free flame retardant thermoplastic elastomer composite material and its preparation, thermoplastic elastomer composite material and its preparation field, can solve problems such as low flame retardant efficiency, and achieve formulation cost Low, 100% recycling, high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A low-smoke halogen-free flame-retardant thermoplastic elastomer composite material, the raw material formula of which is as follows:

[0038] raw material weight percent

[0039] SEBS 26%

[0040] Paraffin oil 20%

[0041] Polypropylene 13%

[0042] Magnesium Hydroxide 30%

[0043] Expandable graphite 8.0%

[0044] Zinc borate 1.8%

[0045] Lubricant 1.0%

[0046] B215 0.2%

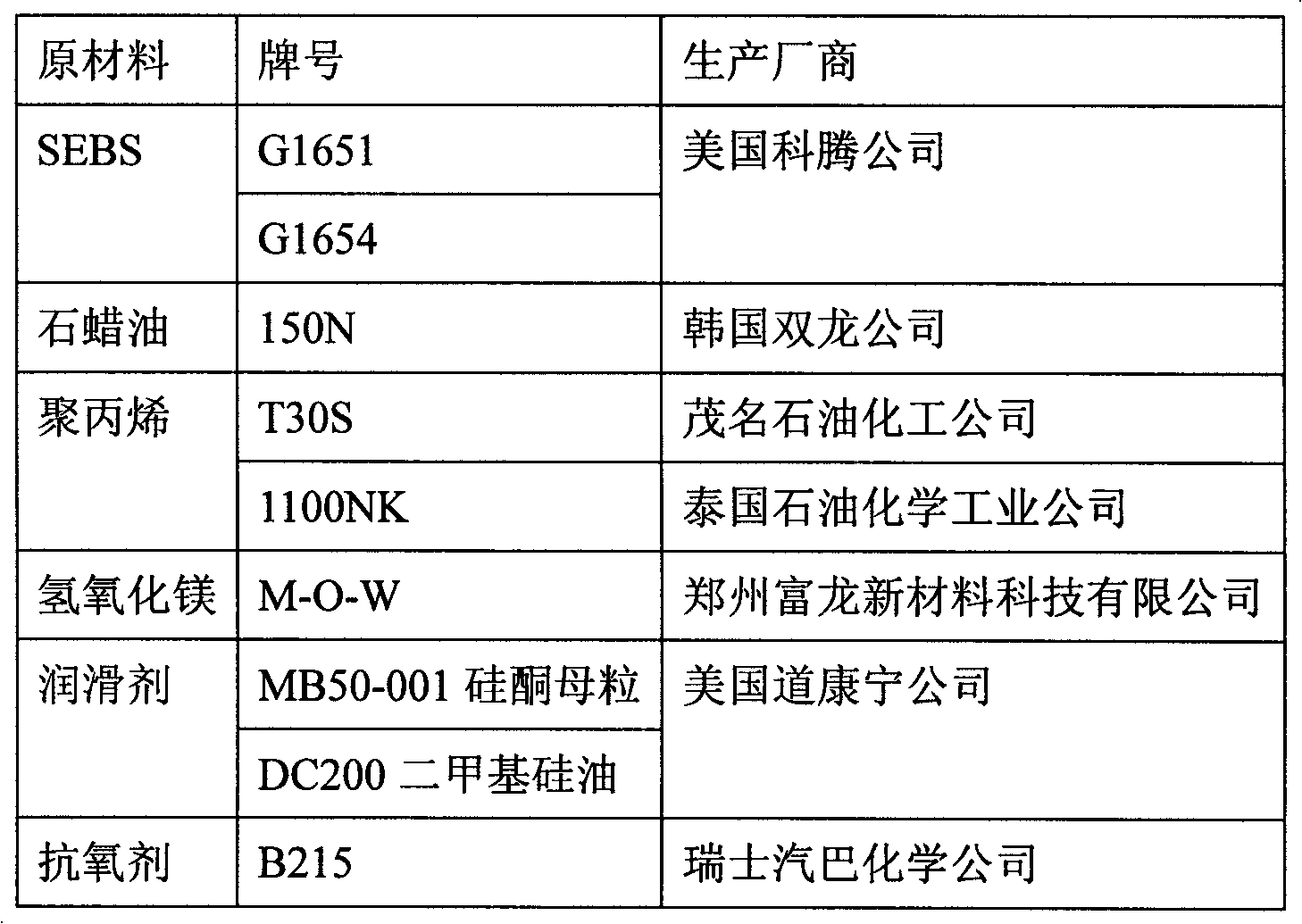

[0047] The grade of SEBS is G1651, the polypropylene is Maoming Petrochemical T30S, MFR=3.0g / 10min; the average particle size of magnesium hydroxide produced by Zhengzhou Fulong New Material Technology Co., Ltd. is less than 2 microns, which is surface-modified magnesium hydroxide The carbon content of expandable graphite is 99%, the expansion volume is 180mL / g, and the particle size is 0.25mm; zinc borate is commercially available 2ZnO.3B 2 o 3 .3.5H 2 O, zinc borate ZB-2335 from Shandong Zibo Wuwei Industrial Co., Ltd., the temperature of decrystallization water is 320°C; the lubricant...

Embodiment 2

[0053] A low-smoke halogen-free flame-retardant thermoplastic elastomer composite material, the raw material formula of which is as follows:

[0054] raw material weight percent

[0055] SEBS 30%

[0056] Paraffin oil 15%

[0057] Polypropylene 15%

[0058] Magnesium Hydroxide 30%

[0059] Expandable graphite 6.0%

[0060] Organic modified montmorillonite 2.5%

[0061] Lubricant 1.2%

[0062] B215 0.3%

[0063] The grade of SEBS is G1651, the polypropylene is Maoming Petrochemical T30S, MFR=3.0g / 10min; the average particle size of magnesium hydroxide produced by Zhengzhou Fulong New Material Technology Co., Ltd. is less than 2 microns, which is surface-modified magnesium hydroxide The carbon content of expandable graphite is 95%, the expansion volume is 220mL / g, and the particle size is 0.18mm; the interlayer distance of organically modified montmorillonite is 3.8nm; the lubricant is DC200 dimethyl silicone oil, and the viscosity is 12500CST.

[0064] The preparation m...

Embodiment 3

[0069] A low-smoke halogen-free flame-retardant thermoplastic elastomer composite material, the raw material formula of which is as follows:

[0070] raw material weight percent

[0071] SEBS 24%

[0072] Paraffin oil 12%

[0073] Polypropylene 12%

[0074] Magnesium Hydroxide 46%

[0075] Expandable graphite 3.0%

[0076] Fumed silica 1.0%

[0077] Lubricant 1.8%

[0078] B215 0.2%

[0079] The grade of SEBS is G1651, the polypropylene is Thai Petrochemical 1100NK, MFR=11.0g / 10min; the average particle size of magnesium hydroxide produced by Zhengzhou Fulong New Material Technology Co., Ltd. is less than 2 microns, which is surface-modified magnesium hydroxide The carbon content of expandable graphite is 99%, the expansion volume is 250mL / g, and the particle size is 0.15mm; the fumed silica is the fumed silica HL-200 of Guangzhou Jibisheng Technology Industrial Co., Ltd.; the lubricant is silicon Ketone masterbatch MB50-001.

[0080] The preparation method of above-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Expansion volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com