Rotary type electric field induction generator

An electric field induction, rotary technology, applied in electrical components, electromechanical devices, etc., can solve the problems of small power/weight ratio, low conversion efficiency, large heat generation, etc., achieve high power/weight ratio, less use, and heat generation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

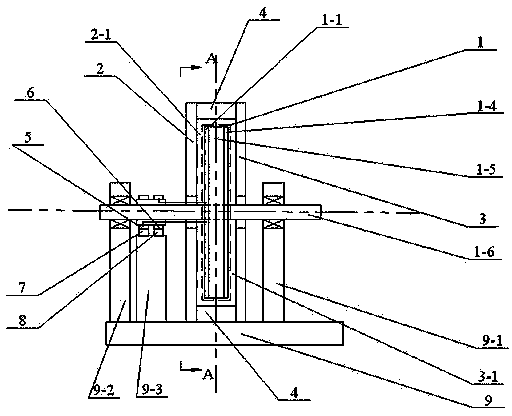

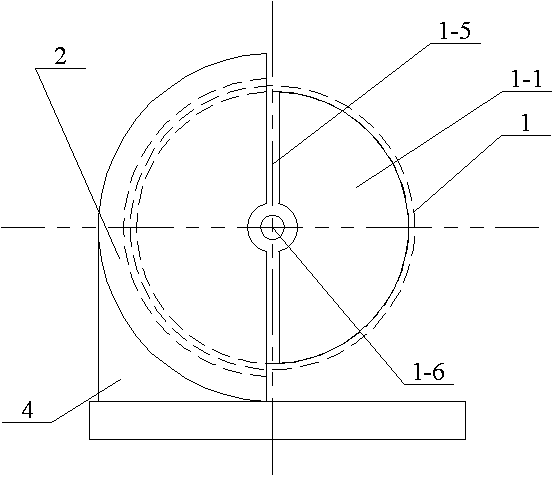

[0009] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 Describe this embodiment, this embodiment consists of disc rotor 1, first semicircular conductive sheet metal stator 2, second semicircular conductive sheet metal stator 3, stator insulating support 4, first annular copper ring 5, second Annular copper ring 6, first electric brush 7, second electric brush 8, base 9;

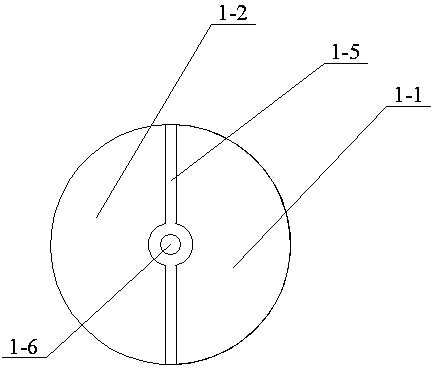

[0010] The disc rotor 1 is composed of a first semicircular conductive metal sheet 1-1, a second semicircular conductive metal sheet 1-2, a third semicircular conductive metal sheet 1-3, a fourth semicircular conductive metal sheet 1- 4. Disc-shaped insulating substrate 1-5 and rotating shaft 1-6; a plane of the first semicircular conductive metal sheet 1-1 and a plane of the second semicircular conductive metal sheet 1-2 are connected to the disc-shaped On a plane of the insulating substrate 1-5, a plane of the third semicircular conductive metal sheet 1-3 and a plan...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination Figure 5 To illustrate this embodiment, a magnetic coupling 10 and a sealed casing 11 are added on the basis of the specific embodiment 1; all the components described in the specific embodiment 1 are arranged in the sealed casing 11 and vacuumized, and the disc-shaped rotor One end of the rotating shaft 1-6 of 1 is magnetically connected with the rotating shaft of the external prime mover through a magnetic coupling 10 . Other compositions and connections are the same as those in the first embodiment.

[0013] The higher the vacuum degree, the higher the breakdown voltage, which can effectively increase the power generation per unit volume, and at the same time reduce the rotating gas resistance, thereby improving efficiency.

[0014] Working principle: Rotate the disk rotor 1, when the first semicircular conductive metal sheet 1-1 and the fourth semicircular conductive metal sheet 1-4 or the second semicircular conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com