Composite isopipe

A fusion and groove wall technology, applied in the direction of manufacturing tools, glass molding, glass manufacturing equipment, etc., can solve the problem of expensive integral forming body, achieve the effect of reducing average cost, reducing material consumption, and reducing weight load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

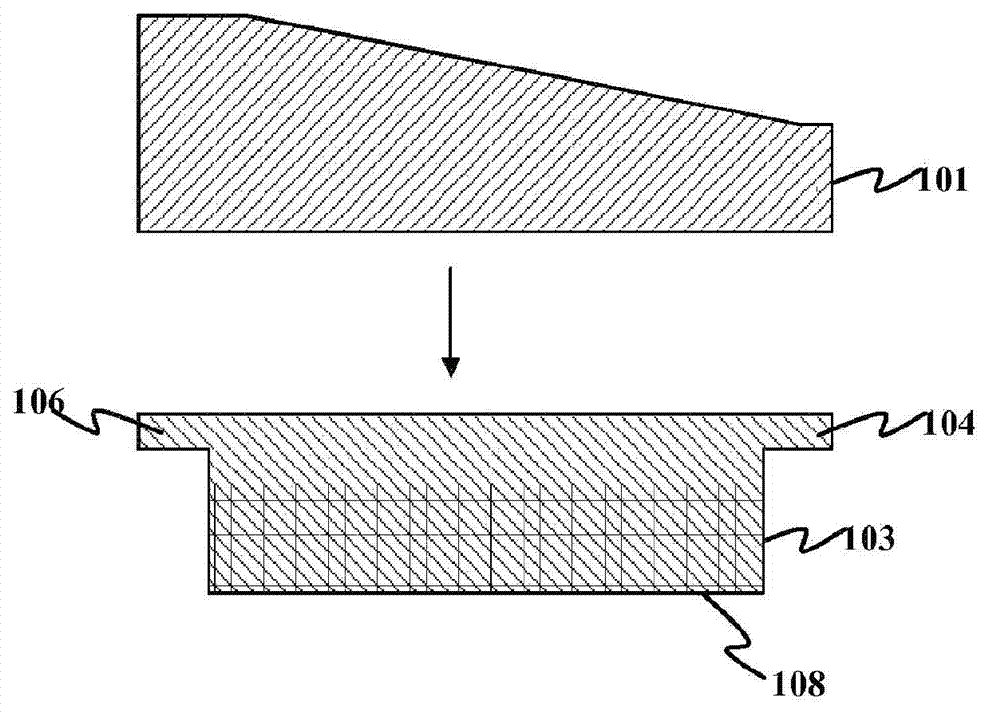

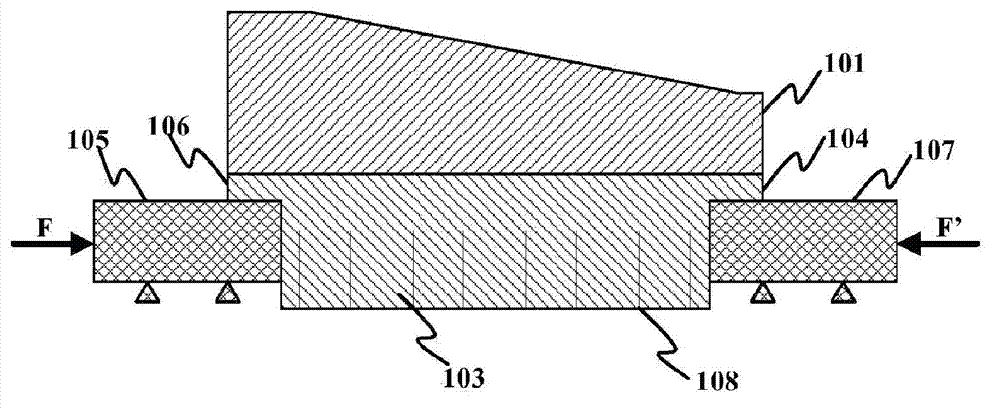

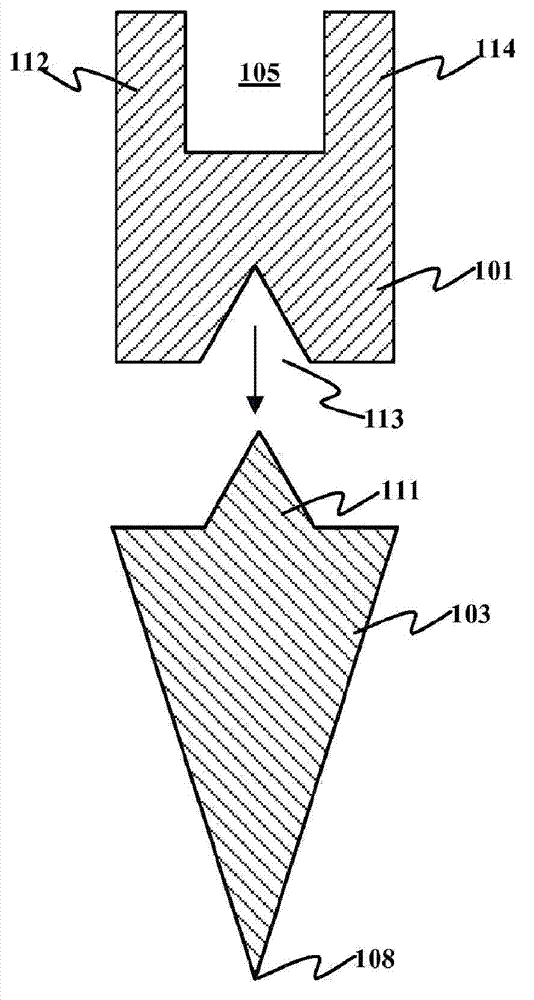

[0075] A composite isopipe containing an upper surface made of α-SiC operated at a root temperature of 1164°C, a weir temperature of 1221°C and a pressure F of 6000 psi Part 101 and lower part 103, 79 inches (2000 mm) long, fabricated from zircon. Figure 7 The estimated shape change at the interface between the upper and lower parts is shown. The data on the horizontal axis is the distance from the pressure end of the forming body (that is, the end of the forming body that is directly subjected to the pressure F relative to the glass melt inlet position), and the data on the vertical axis is the deviation rate, and the unit is micron / year . Curve 703 shows the shape of the lower surface of the upper part 101 , and curve 705 shows the shape of the upper surface of the lower part 103 . Distance 701 shows the maximum gap between the lower surface of upper part 101 and the upper surface of lower part 103 . As expected, there is essentially no shape change in the top piece as i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com