Self-control air lifter

A pneumatic lifting and lifting platform technology, applied in the field of lifting platforms, can solve the problems of not being able to meet the requirements, occupying space with electricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

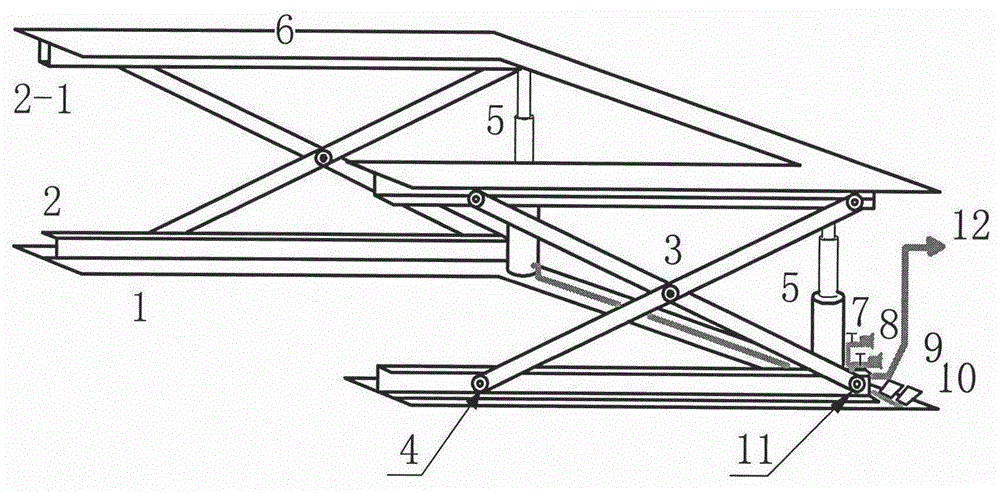

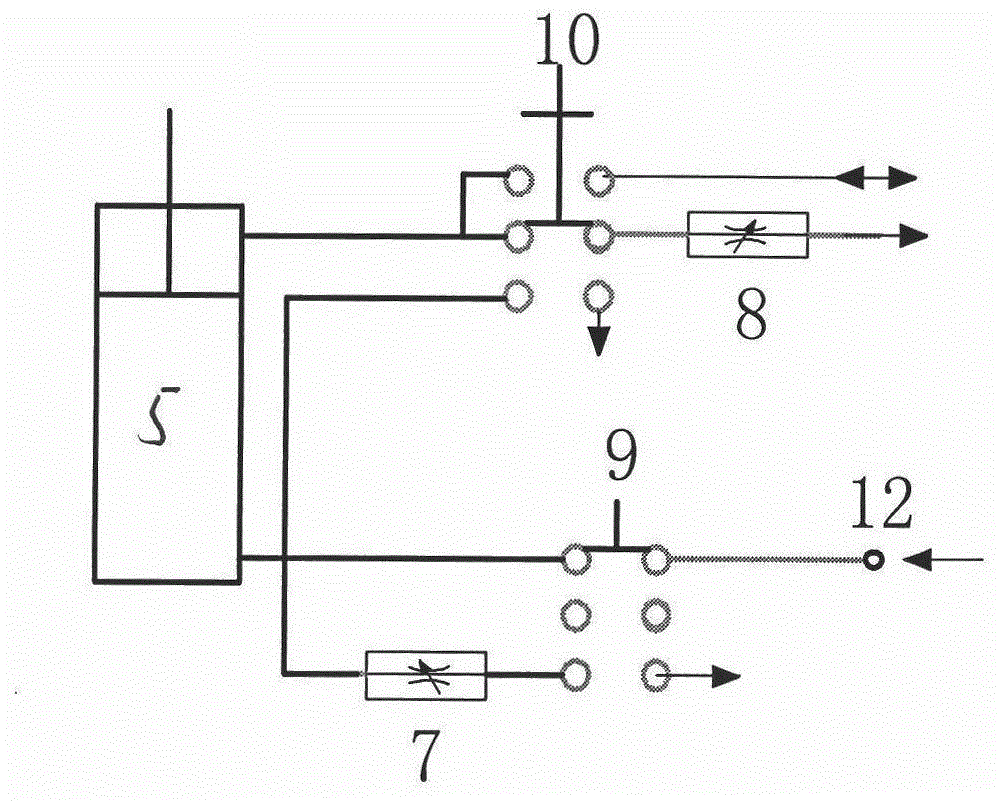

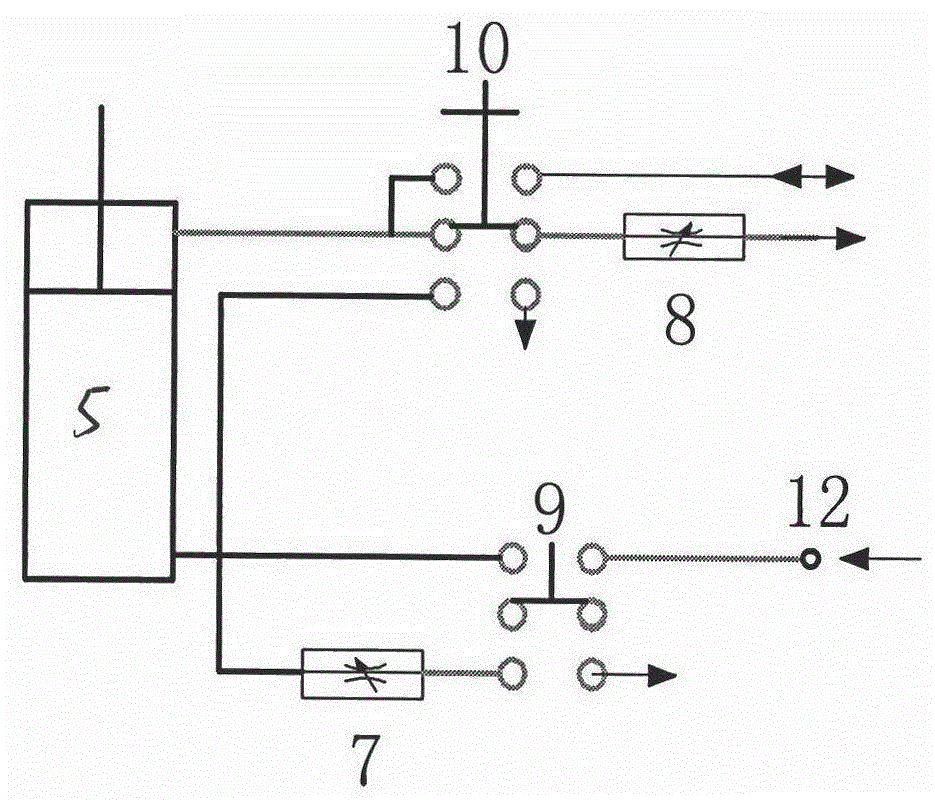

[0009] According to the present invention, the automatic control pneumatic lifting platform figure 1 as shown, figure 2 As shown, the upper and lower fixing mechanism of the self-control pneumatic lifting platform of the present invention is based on the base 1, and the upper chute 2 is installed on the base, and the upper chute 2-1 is installed under the table top 6; The balance fork 3 is installed in the middle of -1, and the balance fork positioning shaft 11 is positioned on one end of the upper chute 2-1 of the glide groove 2. The cylinder 5 lifts and slides, and the balance fork 3 keeps the table 6 stable when it rises and falls; the pneumatic lifting mechanism is composed of the cylinder 5 and is installed between the base and the table 6 to support the height of the table 6; the pneumatic control mechanism is used by the descending throttle valve 7 for the cylinder 5. The air flow adjustment when descending under the action of gravity is installed on the lower part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com