Calendaring glass thickness measurement feeler gauge

A glass thickness and feeler gauge technology, applied in mechanical thickness measurement and other directions, can solve the problems of inability to improve product quality in time, reduce production efficiency, waste of resources, etc., and achieve the effect of convenient and effective calendering regulation, improving production efficiency and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

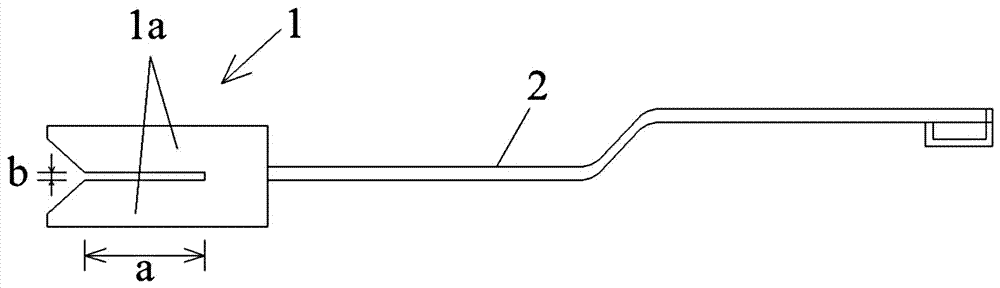

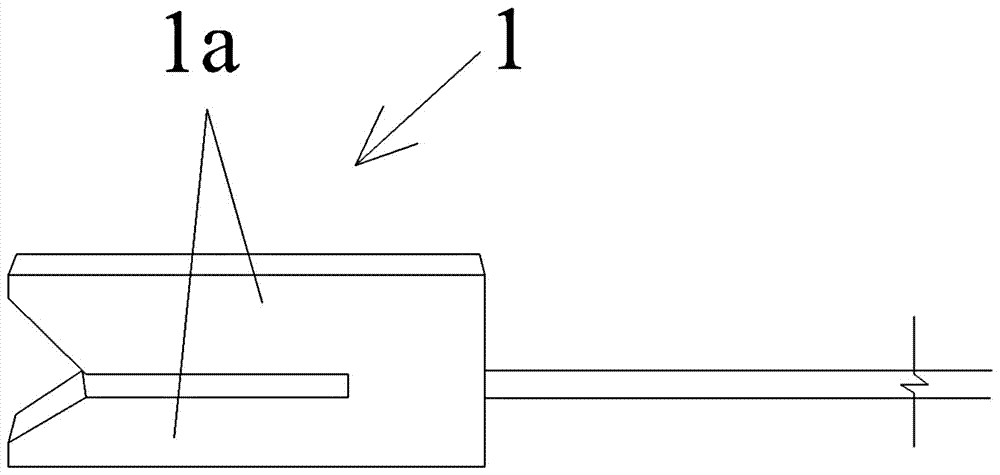

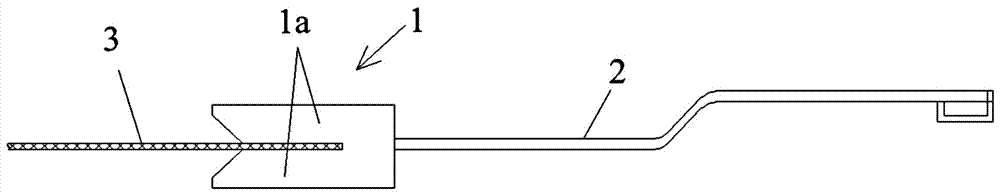

[0015] Such as figure 1 As shown, the present invention provides a feeler gauge for measuring the thickness of rolled glass, which includes a connected ruler head and a handle 2. The ruler head 1 is composed of two connected fork teeth 1a to form a "concave" fork shape. The closed end of the ruler head 1 is connected to the The handles 2 are connected, the opening end of the ruler head 1 is the measuring end, and the opening depth a of the ruler head 1 is 50-60mm; the gap b between the two fork teeth 1a is 0.05-0.1mm greater than the rolling thickness of the rolled glass; preferably, the two The measuring end of each fork tine 1a is inclined towards the gap; the withstand temperature of the feeler gauge is ≥1200°C; in order to adapt to the different thicknesses of the glass rolled out by the calender, different specifications of the ruler can be made to connect with the handle to meet different measurements According to the requirement, according to the most frequently used si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com