Sleeve confined buckling-restrained brace

An anti-buckling energy-dissipating and sleeve technology, applied in earthquake-proofing, building components, etc., can solve the problems of loss of restraint and anti-buckling effect, and reduced energy-dissipation capacity, and achieve strong energy-dissipation capacity, improved energy-dissipation capacity, and good earthquake resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

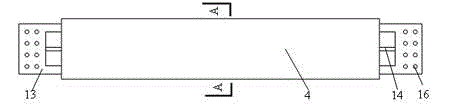

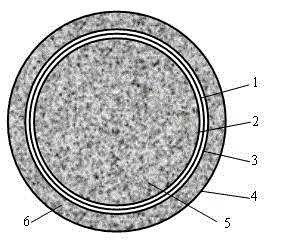

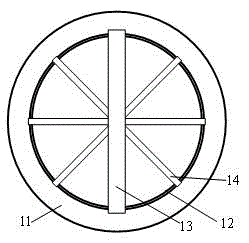

[0023] like Figure 1~Figure 3 As shown, the sleeve-constrained buckling-resistant energy-dissipating support includes energy-dissipating round steel pipe 1, inner isolated thin-walled round steel pipe 2, outer isolated thin-walled round steel pipe 3, outer bound round steel pipe 4, inner bound concrete 5, outer bound concrete 6, and end plate 11 , reinforced round steel pipe 12, mounting plate 13, reinforcing rib 14 and screw hole 16.

[0024] The inner isolated thin-walled round steel pipe 2, the energy-consuming round steel pipe 1, the outer isolated thin-walled round steel pipe 3 and the outer constrained round steel pipe 4 are arranged sequentially from the inside to the outside with the same center; Confinement concrete 6; Inner beam concrete 5 is poured inside the inner isolated thin-walled circular steel pipe 2. Reinforced round steel pipes 12 are arranged at both ends of the energy-dissipating round steel pipe 1; Screw holes 16 are arranged on the mounting plate 13,...

Embodiment 2

[0026] like Figure 4-6 As shown, the buckling-resistant energy-dissipating brace constrained by the sleeve includes energy-dissipating square steel pipe 7, inner isolated thin-walled square steel pipe 8, outer isolated thin-walled square steel pipe 9, outer restrained square steel pipe 10, inner restrained concrete 5, outer restrained concrete 6, and end plate 11 , mounting plate 13, reinforcing rib 14, strengthening square steel pipe 15 and screw hole 16. The inner isolated thin-walled square steel pipe 8 , the energy-consuming square steel pipe 7 , the outer isolated thin-walled square steel pipe 9 and the outer constrained square steel pipe 10 are arranged sequentially from inside to outside with the same center. Externally bound concrete 6 is poured between the outer isolated thin-walled square steel pipe 9 and the outer bounded square steel pipe 10; inner bounded concrete 5 is poured inside the inner isolated thin-walled square steel pipe 8. Reinforced square steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com