Dustproof feed inlet of hammer crusher

A technology of hammer crusher and material inlet, which is applied in the direction of grain processing, etc., and can solve the problem of not being able to block the escape of broken materials and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further elaborate the present invention in combination with specific diagrams and specific examples, but it is not intended to limit the protection scope of the present invention.

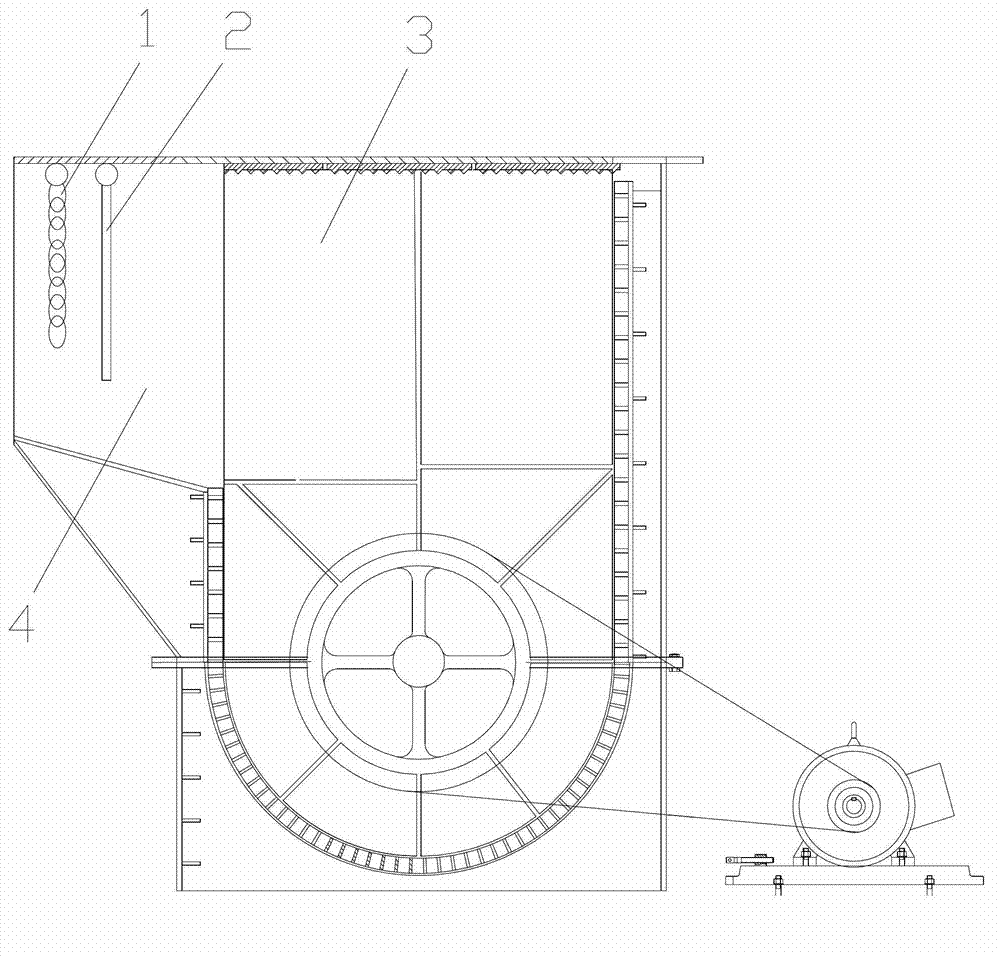

[0012] Please refer to figure 1 , a dust-proof feed inlet of a hammer crusher, including a crushing cavity 3 with a feed inlet 4 arranged on one side, a chain curtain 1 and a belt curtain 2 are arranged inside the feed inlet 4, and the belt curtain 2 is arranged on the chain curtain 1, the upper ends of the chain curtain 1 and the belt curtain 2 are all fixed on the inner wall of the upper plate of the material inlet 4.

[0013] The basic principles, main features and advantages of the present invention have been shown and described above. It is only a specific embodiment of the present invention, but the protection scope of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com