Novel tube-type oil cooler core clean device

A technology for cleaning devices and oil coolers, which is applied to cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., and can solve problems such as inability to thoroughly clean equipment, incomplete cleaning of equipment, and poor heat exchange effect of equipment. , to achieve the effect of being conducive to environmental protection, preventing personnel burns, and high water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

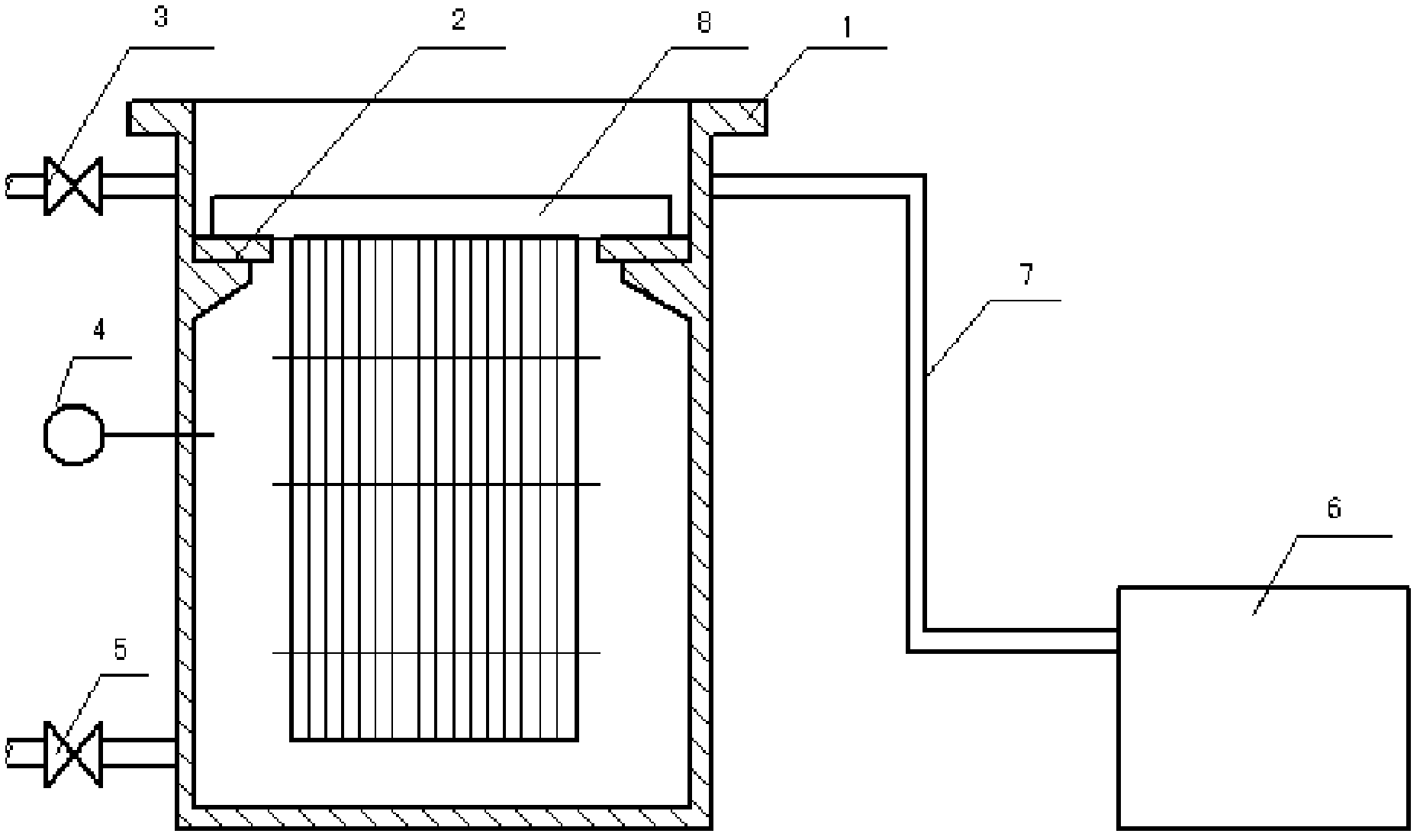

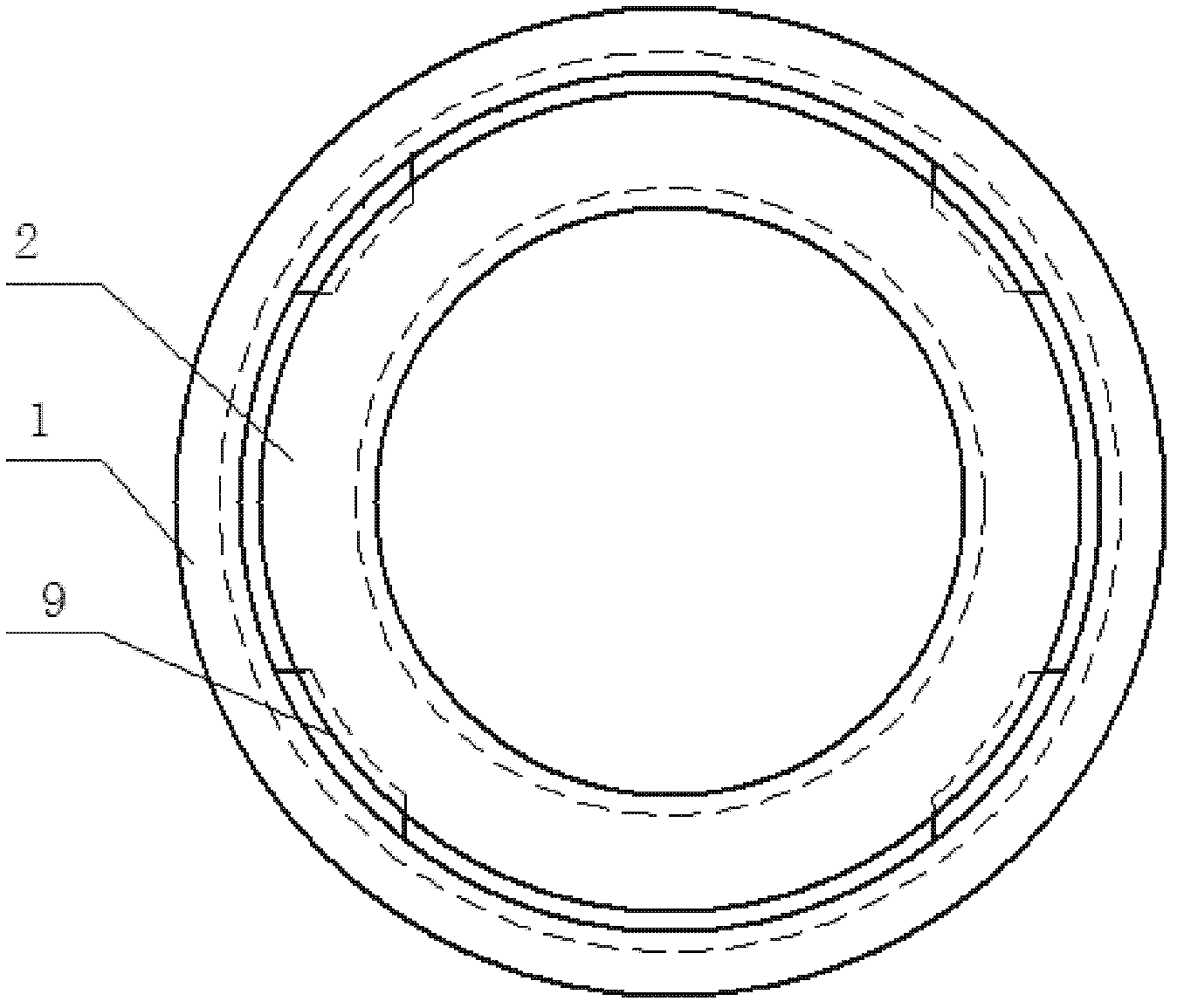

[0020] Such as figure 1 As shown, a new tubular oil cooler core cleaning device, the device includes a cooking cylinder 1, an oil cooler core support ring 2, a water injection valve 3, a thermometer 4, a steam inlet valve 5, and a waste liquid collection box 6. The overflow pipe 7, the water injection valve 3 is connected to the upper part of the boiling cylinder 1 through a pipeline, and injects water into the boiling cylinder, and the steam inlet valve 5 is connected to the lower part of the boiling cylinder 1 through a pipeline, and is used to connect the steam source to the Boiling cylinder, the thermometer 4 is inserted into the boiling cylinder 1 to monitor the temperature change during hot cooking, and the core support ring 2 of the oil cooler is arranged on the inner wall of the special cooking cylinder 1 to play a role in the oil cooler. The core body 8 supports the role of the oil cooler core body 8 when boiling, and the waste liquid collection box 6 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com