Welding jig for filter membrane of air-permeable bottle cap

A welding fixture and filter membrane technology, which is applied in the field of ventilated bottle cap filter membrane welding fixtures, can solve the problems of filter membrane falling out and inability to ensure the cleanliness of cell culture bottles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

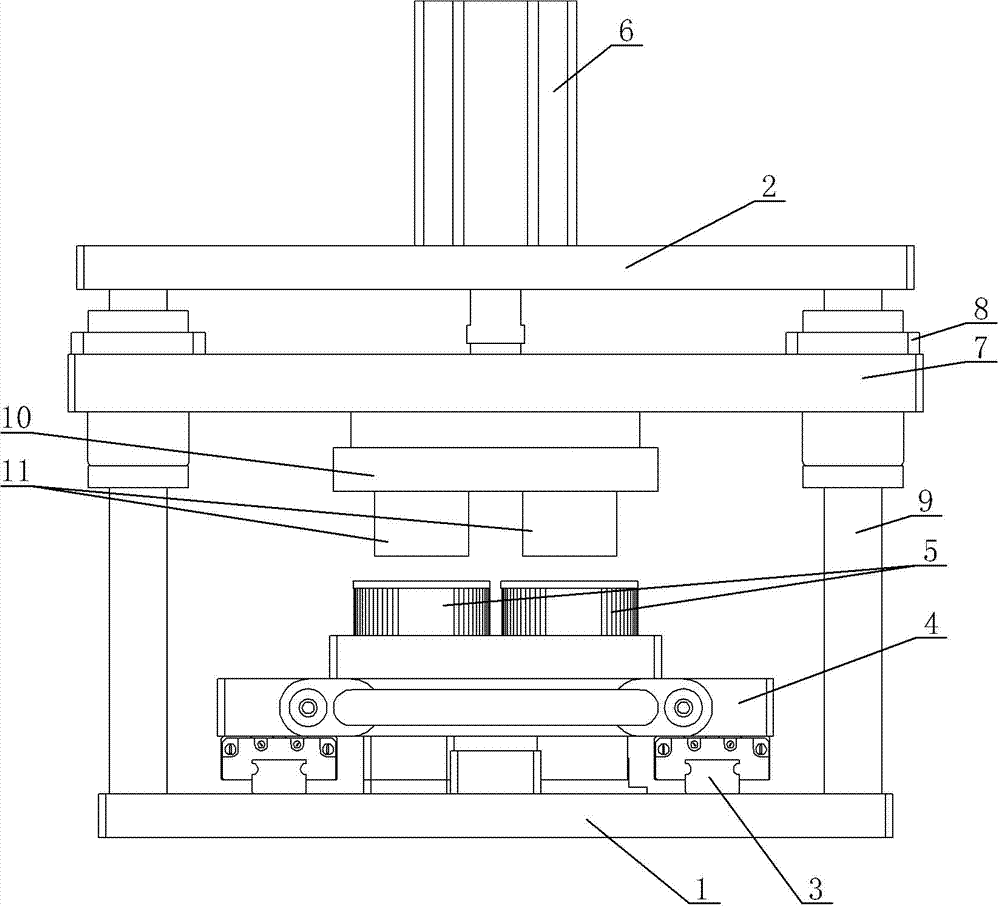

[0007] See figure 1 , which includes a base plate 1, a bracket 2 supported on the base plate 1, a guide rail 3 is provided on the base plate 1, a lower mold base 4 is supported on the guide rail 3, a cover installation groove 5 is arranged on the upper part of the lower mold base 4, and the upper end surface of the bracket 2 is tight. Inherent cylinder 6, the cylinder arm of the cylinder 6 is connected with the upper mold base 7, the four corners of the upper mold base 7 are set on the four columns 9 of the bracket 2 through the bearing 8, and the lower part of the upper mold base 7 is equipped with a heating plate 10, the heating plate A hot riveting head 11 protrudes from the bottom of 10, and the hot riveting head 11 is located directly above the cover installation groove 5 during thermal welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com