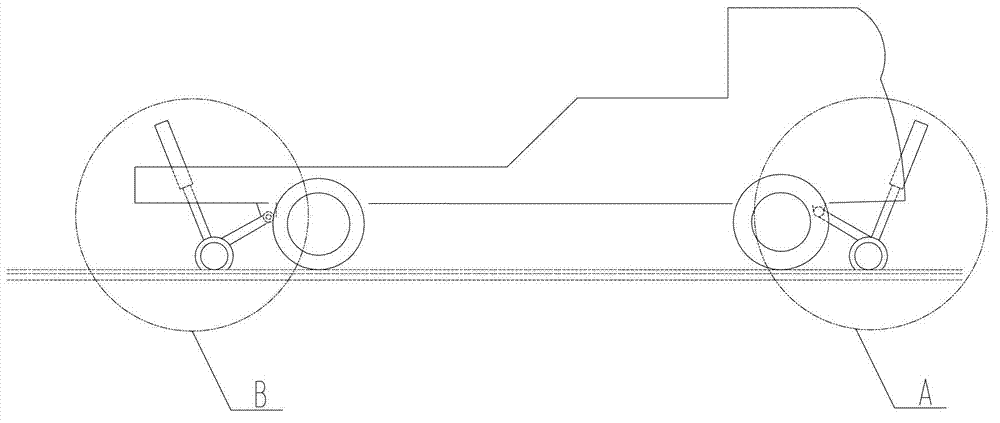

Railway tractor, as well as method, device and system for controlling same

A railway traction and controller technology, applied to track and road dual-purpose vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of insufficient pressure on the guide wheel, failure to raise the rail, and the whole vehicle detached from the rail, so as to improve safety Effects on sex and traction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

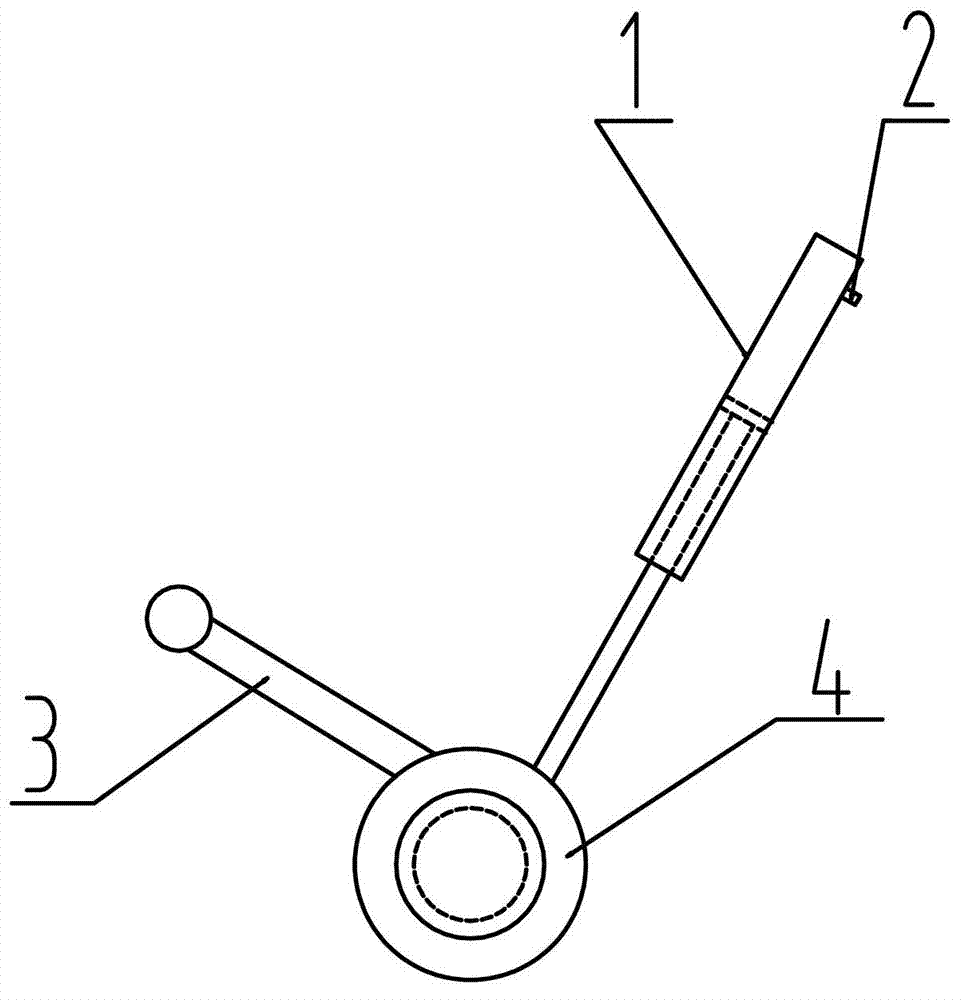

[0030] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0031] Considering that when the railway tractor is running on the rail, the pressure between the guide wheel and the rail is too large or too small, which will cause the road-rail vehicle to fail to run normally, the embodiment of the present invention provides a railway tractor and its control method , devices and systems. The following is described by way of examples.

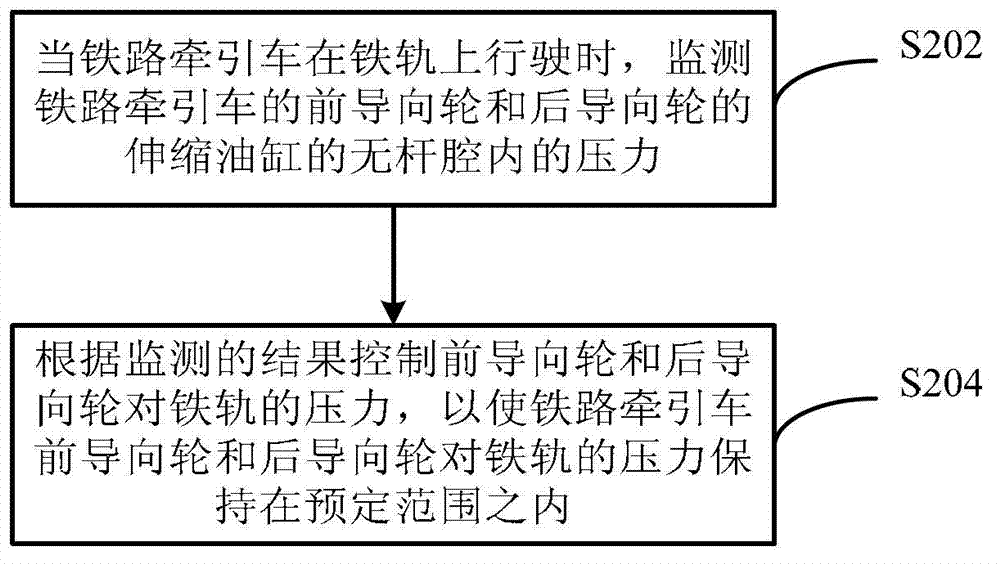

[0032] see figure 2 The control method flowchart of the shown railway tractor, this method can be applied in the controller of railway tractor, this method comprises the following steps:

[0033] Step S202, when the railway tractor is running on the rails, monitor the pressure of the front guide wheel and the rear guide wheel of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com