Ground-rising automatic buckle anti-sports car barrier

A technology for preventing sports cars and car barriers, which is applied in the direction of mandatory railway car stops, railway car body parts, transportation and packaging, etc., can solve the problems of weakened strength, potential safety hazards, and the inability of wire rope to be pulled, and achieves interception, guaranteed strength, Effect of Cantilever Structure Elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

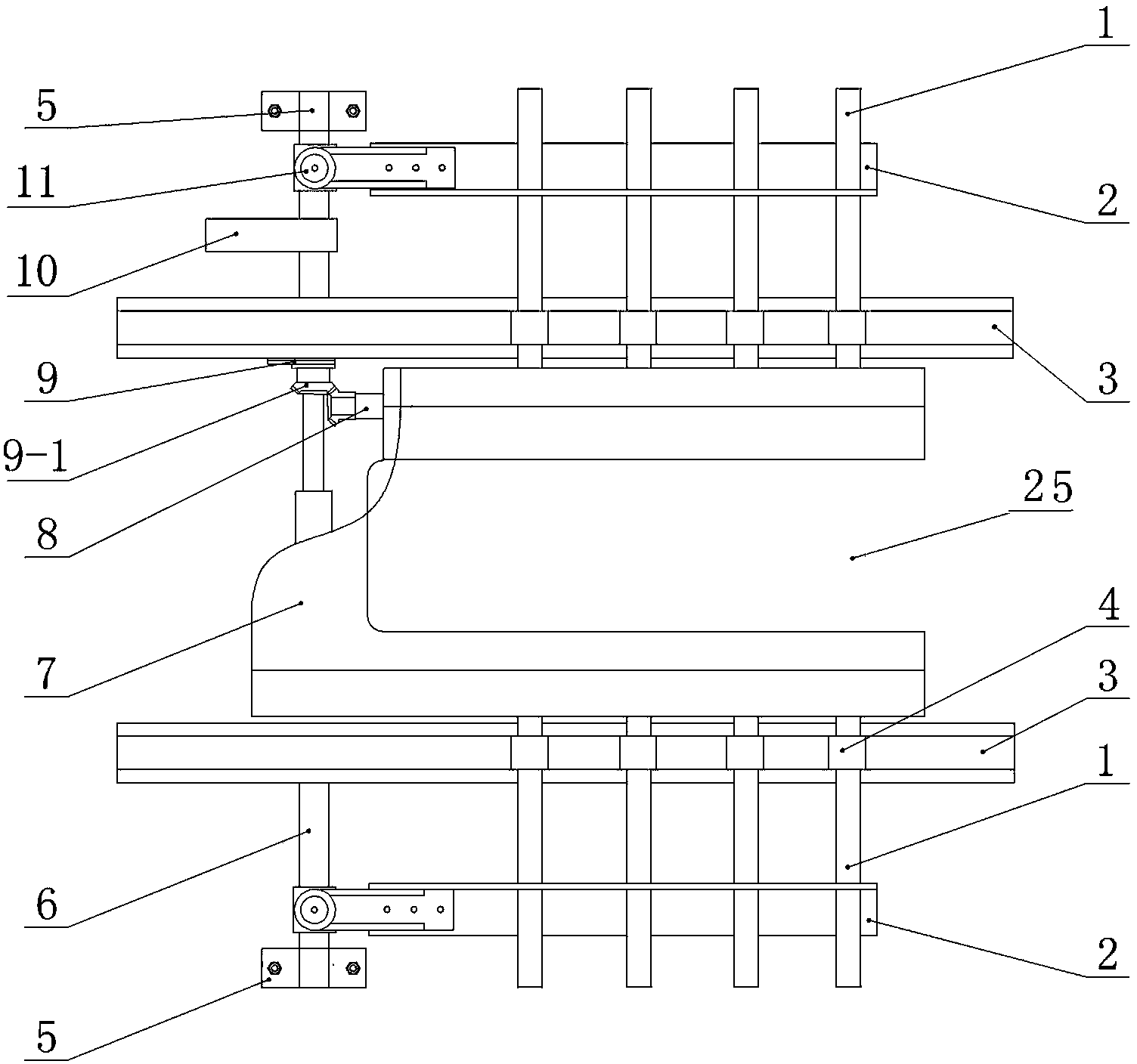

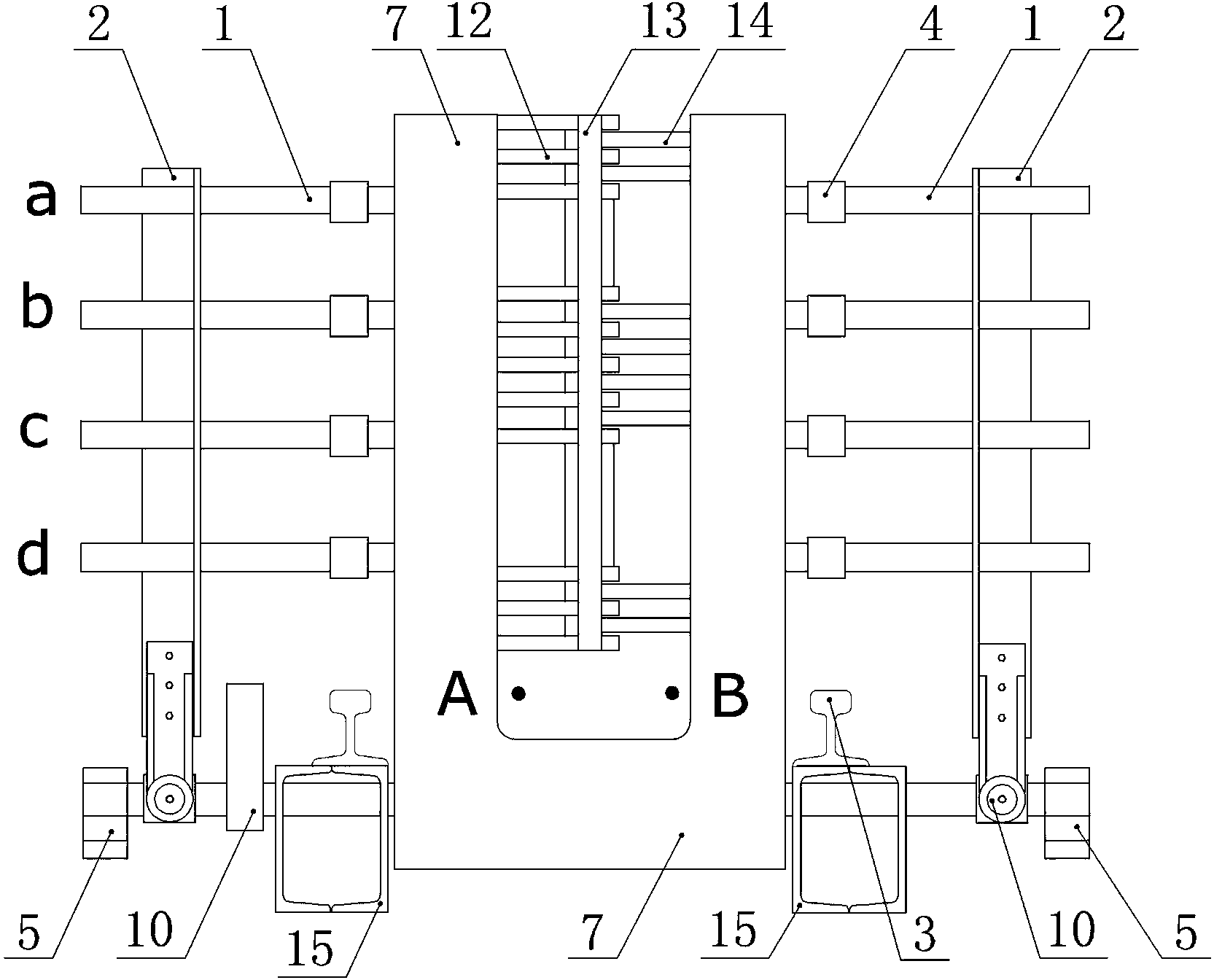

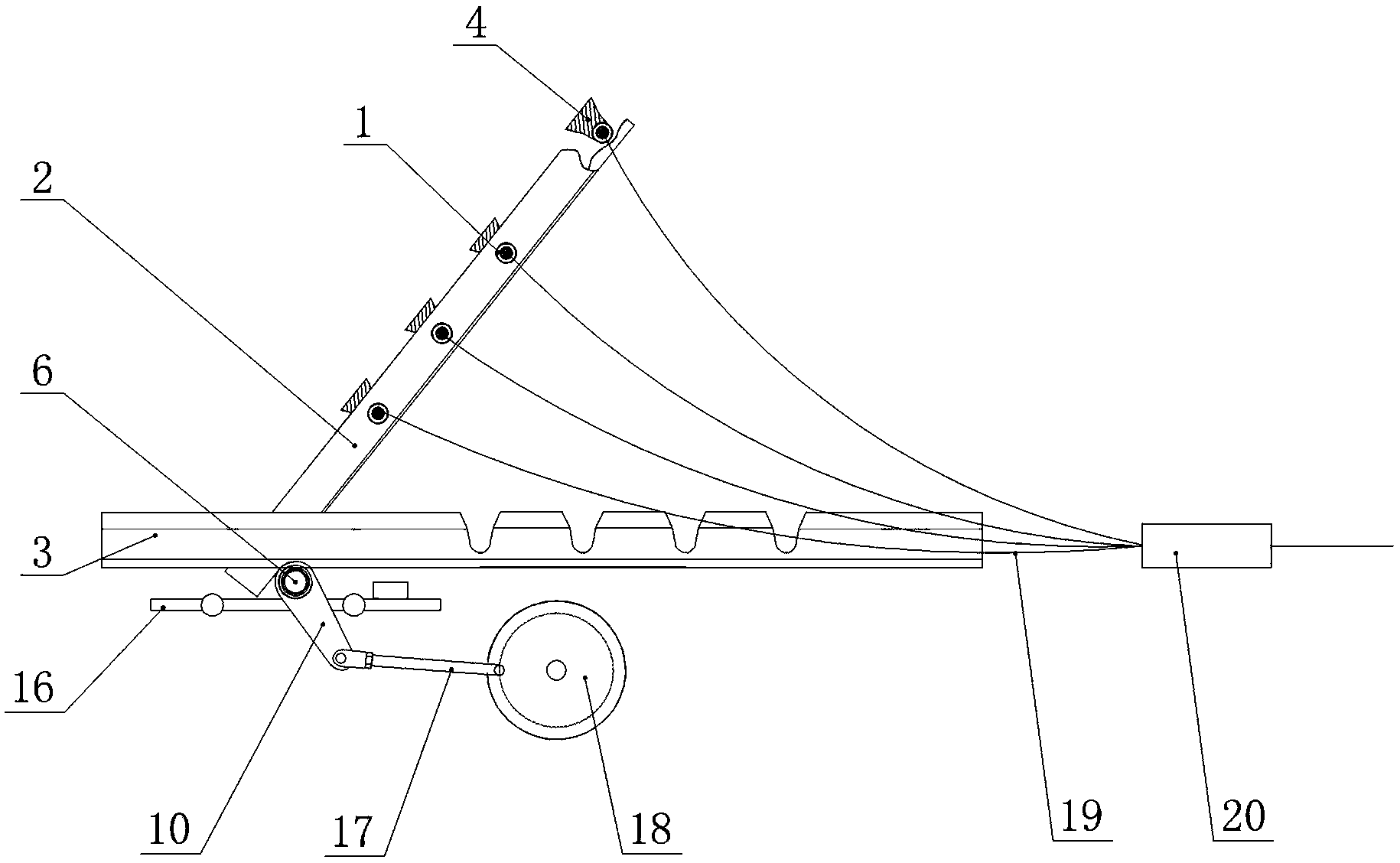

[0027] Such as figure 1 and figure 2 As shown, the structure diagrams of the car barrier of the present invention in the lowered and raised states are respectively provided, which include the slotted track 3, the swing shaft 6, the bearing seat 5, the swing arm 2, the plug assembly 11, and the supporting steel pipe 1 , Car retaining frame 7, left hasp 12, right hasp 14, central shaft 13, hasp drive shaft 8, large gear angle adjustment assembly 9, base 15. The two slotted rails 3 are arranged in parallel, and are used to cooperate with the mine car rails in the roadway; the swing shaft 6 is placed at the bottom of the slotted rail 3, and the two ends are respectively fixed on the two bearing seats 5, in order to facilitate the movement of the swing shaft 6 Assembling and disassembling, the swing shaft 6 can be designed as two half-shaft structures, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com