Control method, equipment and system for slewing jib of tower crane

A technology of slewing arms and jibs, which is applied in the control field of tower crane slewing jibs, can solve problems such as no effective solutions have been proposed, and achieve the effect of enhancing safety and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0033] The embodiment of the present invention considers that the rotating jib between the arm tip and the arm root may be bent during the operation of the tower crane's rotating jib. In order to reduce the torsional force between the arm tip and the arm root as much as possible, the embodiment of the present invention provides A control method, device and system for a slew jib of a tower crane are provided. The following will be described through specific examples.

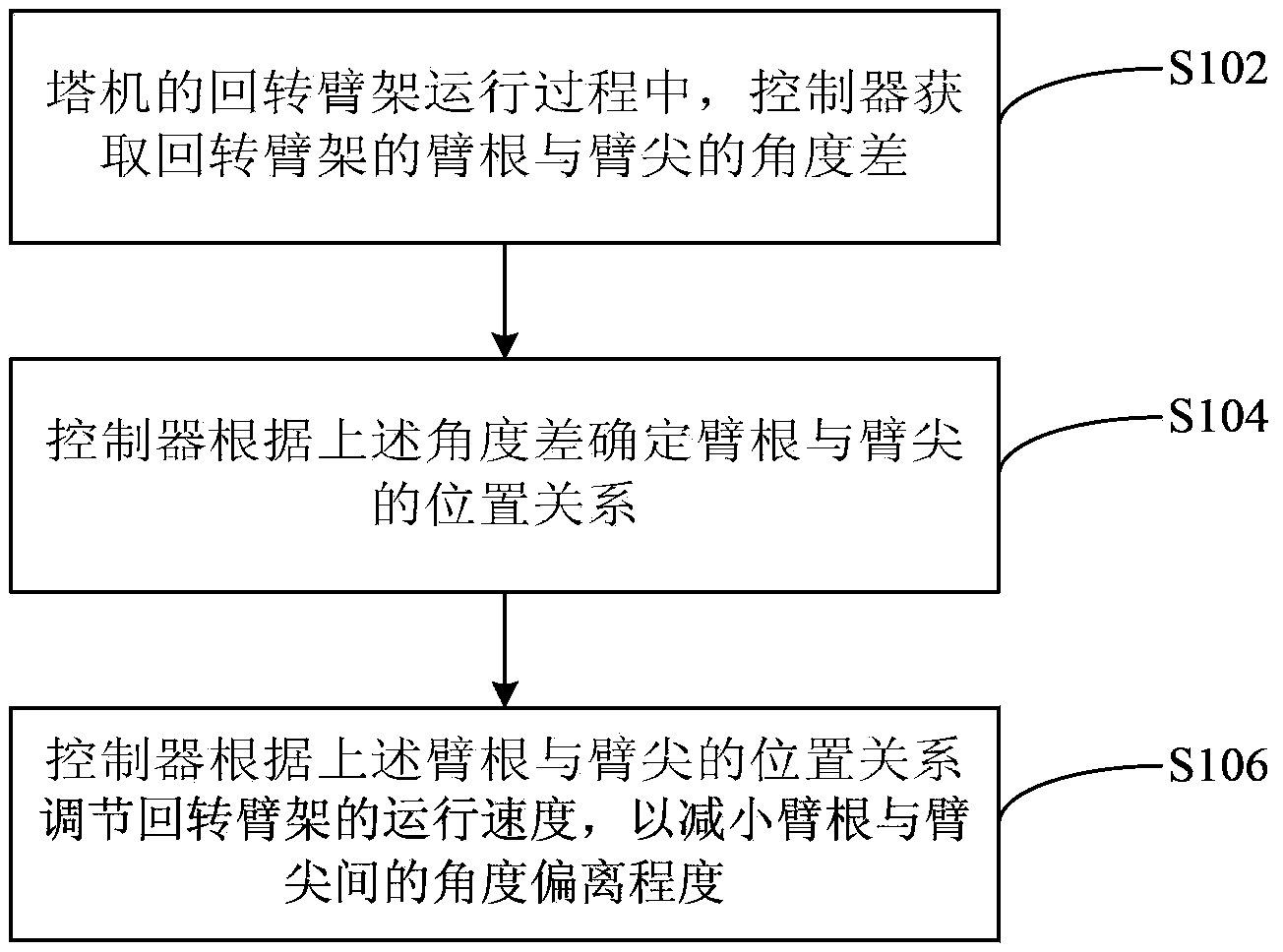

[0034] see figure 1 The flow chart of the control method for the slewing jib of the tower crane is shown. The method is described by taking the application in the controller of the tower crane as an example, and specifically includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com