Braid continuous mercerizing machine and processing method thereof

A mercerizing machine and fiber technology, which is applied in the mercerization of yarn/thread/filament, continuous processing of textile materials, textiles and papermaking, etc., can solve the problem that fibers cannot be effectively mercerized, achieve gloss and strength improvement, and save energy , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

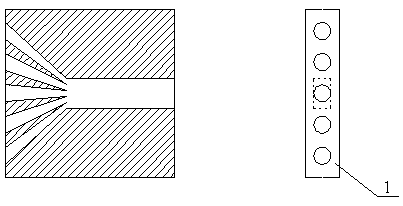

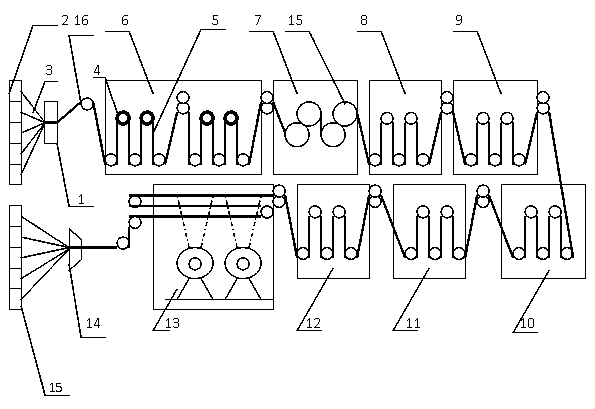

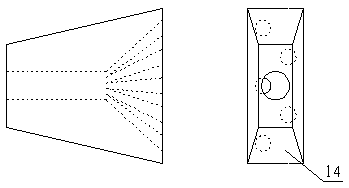

[0032] like figure 1 As shown, the structure of the fiber braid feeder is specifically a plate-like structure with holes at both ends. One end is provided with a single long hole, and the other end is provided with a multi-round hole. After the holes converge, it becomes a single fiber braid; such as image 3 As shown in the figure, the structure of the bell mouth separator is a cone-shaped truncated cone, with a single circular hole at one end and a multi-circular hole at the other end. It is divided into independent fiber braids through the bell mouth divider, which is convenient for the independent coiling of the subsequent channel. Preferably, both the fiber braid feeder and the flare splitter are made of stainless steel.

[0033] attached figure 1 In the middle, 5 fiber braids are respectively connected to the 5 circular holes at the left end, which are merged into a single fiber bundle after passing through the middle channel, and enter the alkali soaking reaction zon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com