Intelligent and high-efficiency brick paving machine

A high-efficiency brick laying machine and intelligent technology, applied in the direction of construction and building construction, can solve the problems of low laying efficiency, low degree of automation, and inability to realize cement filling, etc., and achieve good brick laying quality, strong site adaptability, Rich effects of tile types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

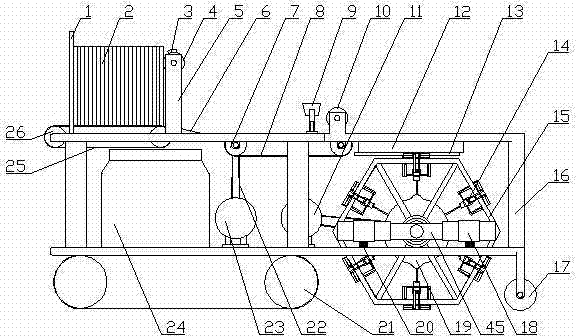

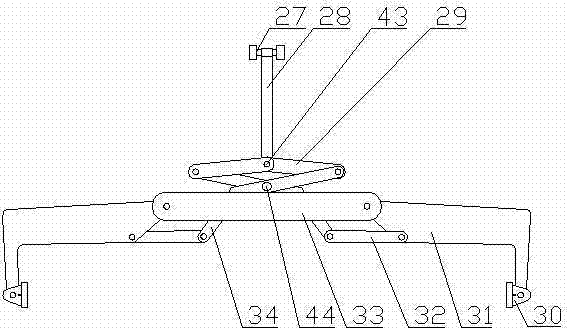

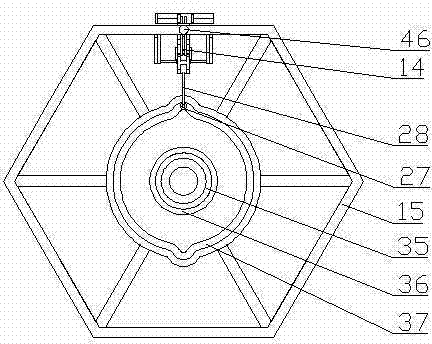

[0022] see Figure 1-5 , the present invention includes a transmission mechanism, a three-dimensional brick transportation mechanism, a roller grouting mechanism, a cam locking mechanism, a hexagonal brick placing mechanism, a brick compacting mechanism, a control module, etc. The coordinated operation of the mechanism provides the corresponding power. The three-dimensional operation mechanism separates and transmits the bricks. The roller brushing mechanism brushes the back of the bricks. The cam locking mechanism completes the clamping and releasing of the bricks. The brick mechanism completes the continuous laying of bricks, the compacting mechanism completes the flattening and compacting of bricks, and the control module completes the control of the movement of the brick laying machine and the coordinated operation of various mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com