Fully automatic intelligent tiling machine

A brick tiling machine, fully automatic technology, applied in the direction of construction, building construction, etc., can solve the problems of high rework rate of single brick, uneven gap, slow paving speed, etc., to achieve fully automatic mechanized operation and reduce labor Strength, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

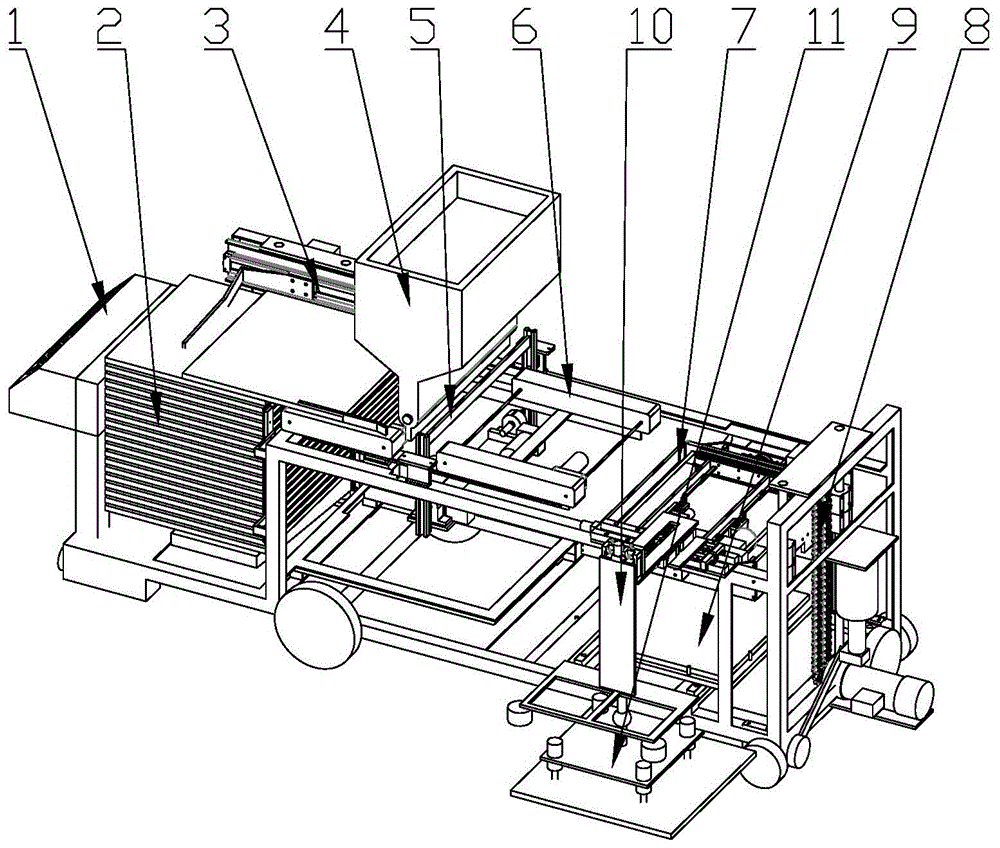

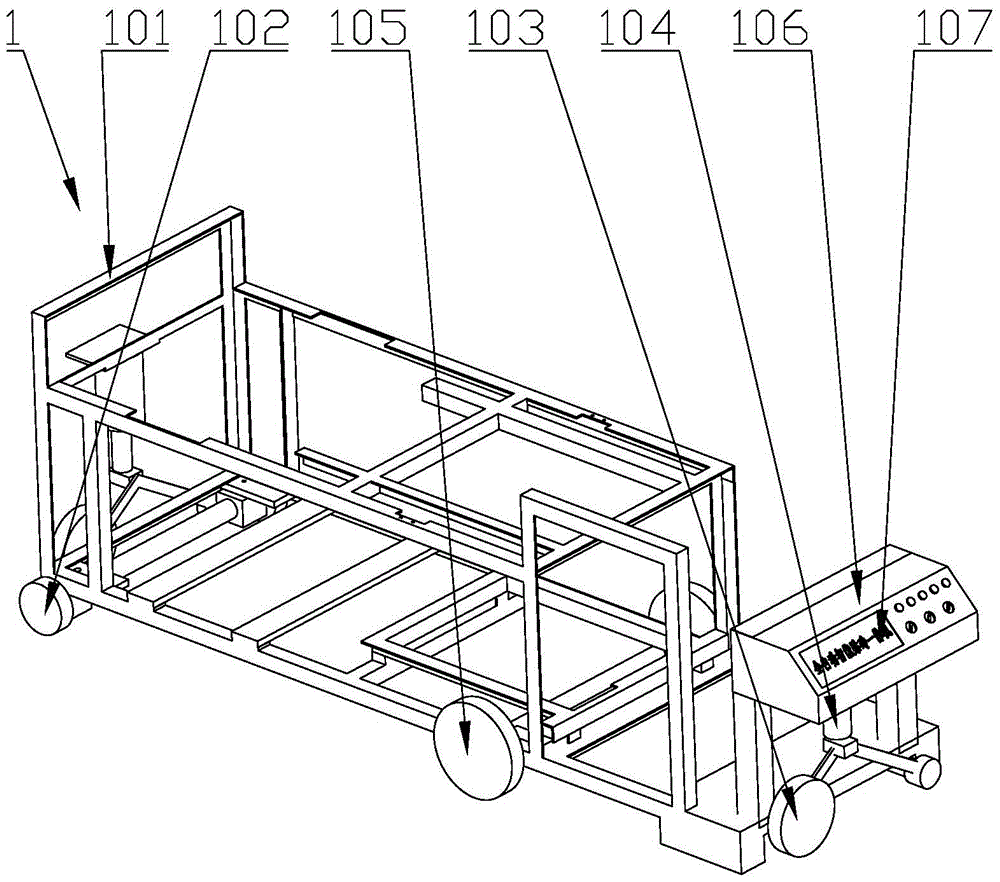

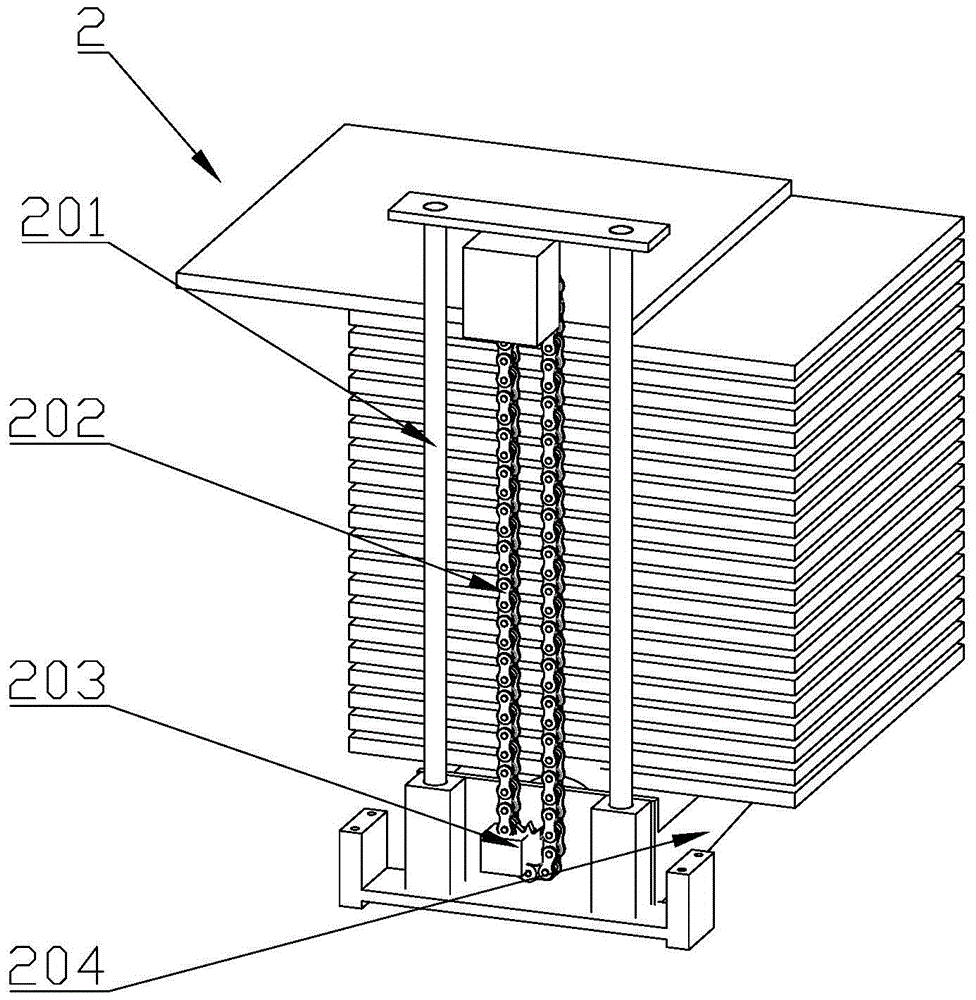

[0048] Such as figure 1 The fully automatic intelligent tile laying machine shown includes frame 1, feeding lifting system 2, automatic pulling system 3, automatic plastering hopper 4, automatic dust scraping mechanism 5, feeding mechanism 6, feeding automatic turning mechanism 7, Feeding automatic lifting table 8, secondary positioning system 9, floor tile four-axis positioning system 10 and measuring and vibrating laying mechanism 11, feeding lifting system 2, material conveying mechanism 6, automatic dust scraping mechanism 5, feeding automatic turning mechanism 7 and the feeding automatic lifting platform 8 are sequentially fixed on the frame 1 along the longitudinal direction of the frame 1. The automatic plastering hopper 4 is located above the front and upper part of the automatic dust scraping mechanism 5, and the secondary positioning system 9 is located below the automatic feeding turning mechanism 7, and the floor tiles are pasted. The four-axis positioning system 1...

Embodiment 2

[0061] Such as Figure 12 As shown, on the basis of embodiment 1, a five-axis positioning system 12 for wall tiles is added, and the end of the five-axis positioning system 12 for wall tiles is connected with a measuring and vibrating paving mechanism 11. The connection mode of the five-axis positioning system 12 for wall tiles is the same as that of the four-axis positioning system 10 for laying floor tiles, and will not be repeated here.

[0062] Such as Figure 13 As shown, the wall tile five-axis positioning system 12 includes a support column 1201, a Z-direction rotation mechanism 1202, an X-axis linear motion mechanism 1001, a Y-axis linear motion mechanism 1002, a Z-axis linear motion mechanism 1003, a Y rotation axis 1203 and a universal The movable coupling 1005, the support column 1201 is movably connected with the Z-direction rotating mechanism 1202, the X-axis linear motion mechanism 1001 is fixed on the Z-direction rotating mechanism 1202, the Z-axis linear motio...

Embodiment 3

[0064] Such as Figure 14 As shown, on the basis of Embodiment 1, a second discharge port 405 is provided on the ash hopper 401, a first discharge pipe 13 is provided on the second discharge port 405, and an ash discharge pipe 13 is provided at the end of the first discharge pipe 13 The material injection port 15 is sprayed to the measuring and vibrating paving mechanism 11 connected with the floor tile four-axis positioning system 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com