Electric vehicle motor end cap pressure bearing feeding and glue applying integrated machine

A technology of electric vehicles and integrated machines, applied in the manufacture of motor generators, electric vehicles, motors, etc., can solve the problems of difficulty in meeting the needs of large-scale production of electric vehicle motors, high labor costs, and low work efficiency, and meet the needs of large The effect of mass production, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

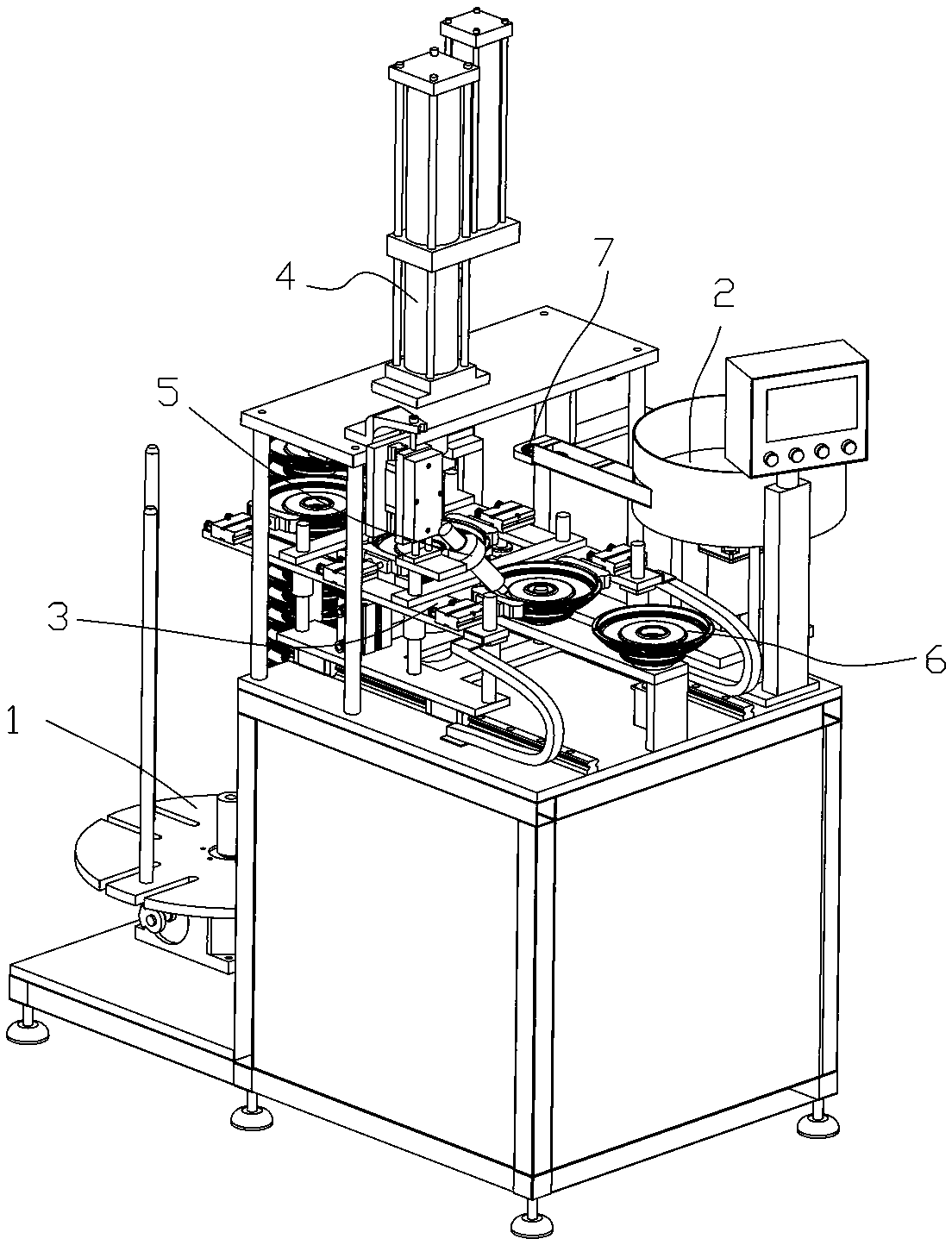

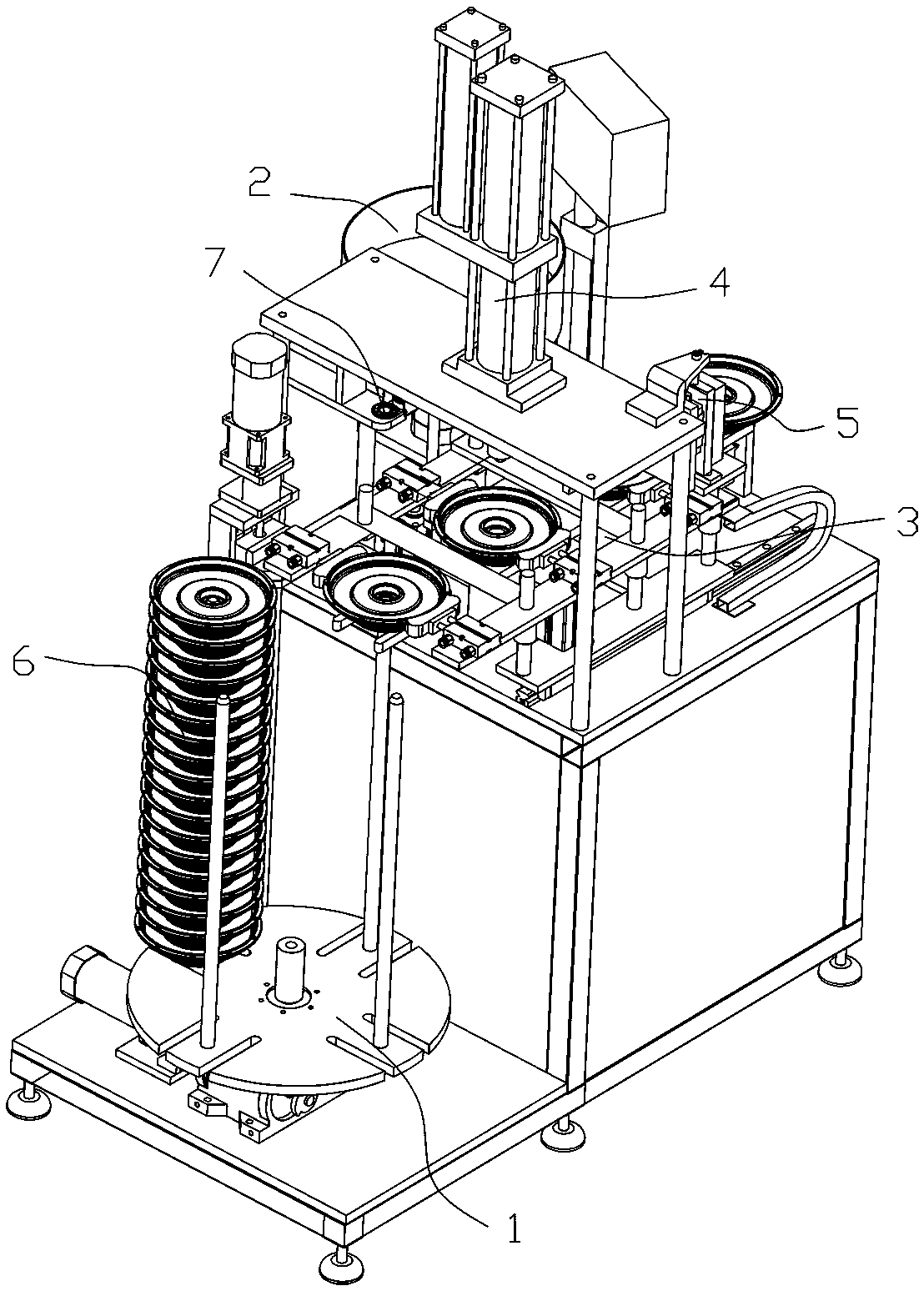

[0024] Such as Figure 1-3 As shown in the figure, an electric vehicle motor end cap press bearing and gluing comprehensive machine mainly includes an end cap feeding mechanism 1, a bearing feeding mechanism 2, a linkage three-clamp mechanism 3, a bearing pressing mechanism 4 and a glue spraying mechanism 5 .

[0025] The end cover feeding mechanism 1 sends the motor end covers 6 one by one to the head of the linkage three chuck mechanism 3 to connect with it, and the bearing feeding mechanism 2 sends the bearing 7 to the top of the linkage three chuck mechanism 3 to connect with the bearing The press-in mechanism 4 is engaged.

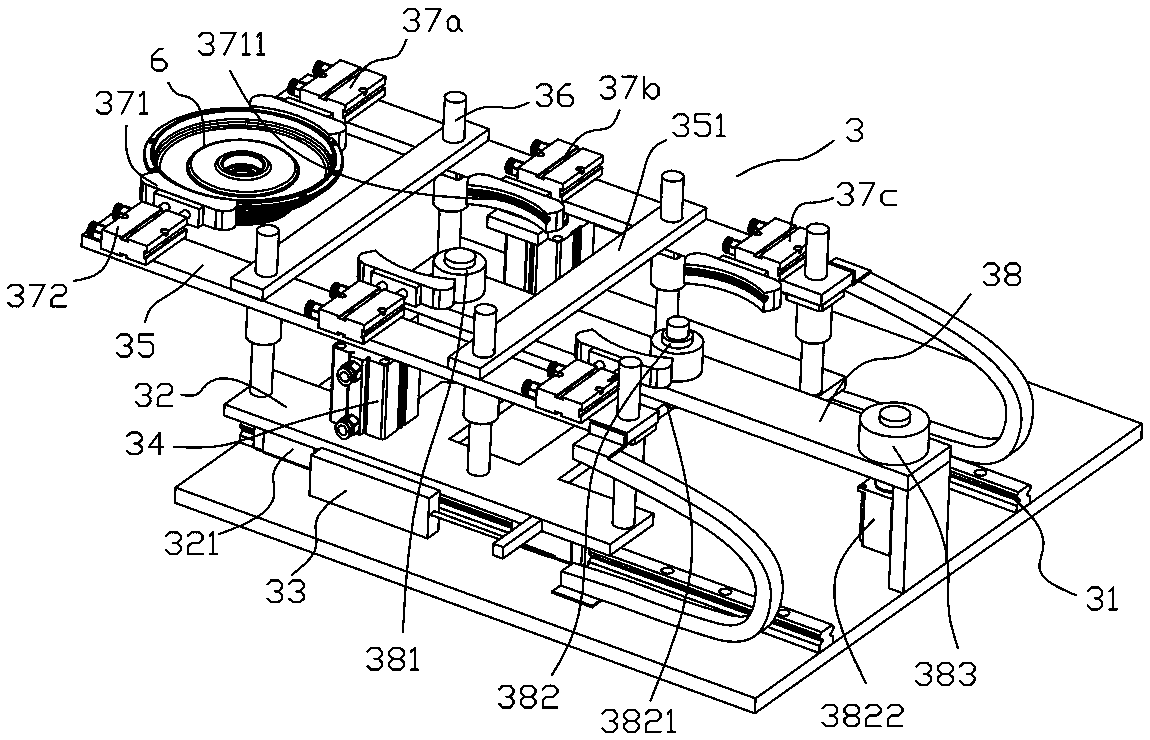

[0026] Described interlocking three chuck mechanism 3 mainly comprises two working slide rails 31 that are arranged on the working platform at intervals in parallel, and two working slide rails 31 are jointly connected to a slide plate 32 through a plurality of slide blocks 321 respectively, and the slide plate 32 is driven by a driving cylinder 33. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com