Conveying device of full-automatic safe deposit box display table

A technology of conveying device and safe deposit box, which is applied in the direction of storage device, transportation and packaging, etc., can solve the problem that it cannot be rotated to change the placement direction of the storage box, cannot be applied to places with small space outside the protective warehouse, and the site adaptability and layout are reasonable. It can improve the adaptability of the site, improve the operation efficiency, and reduce the floor area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

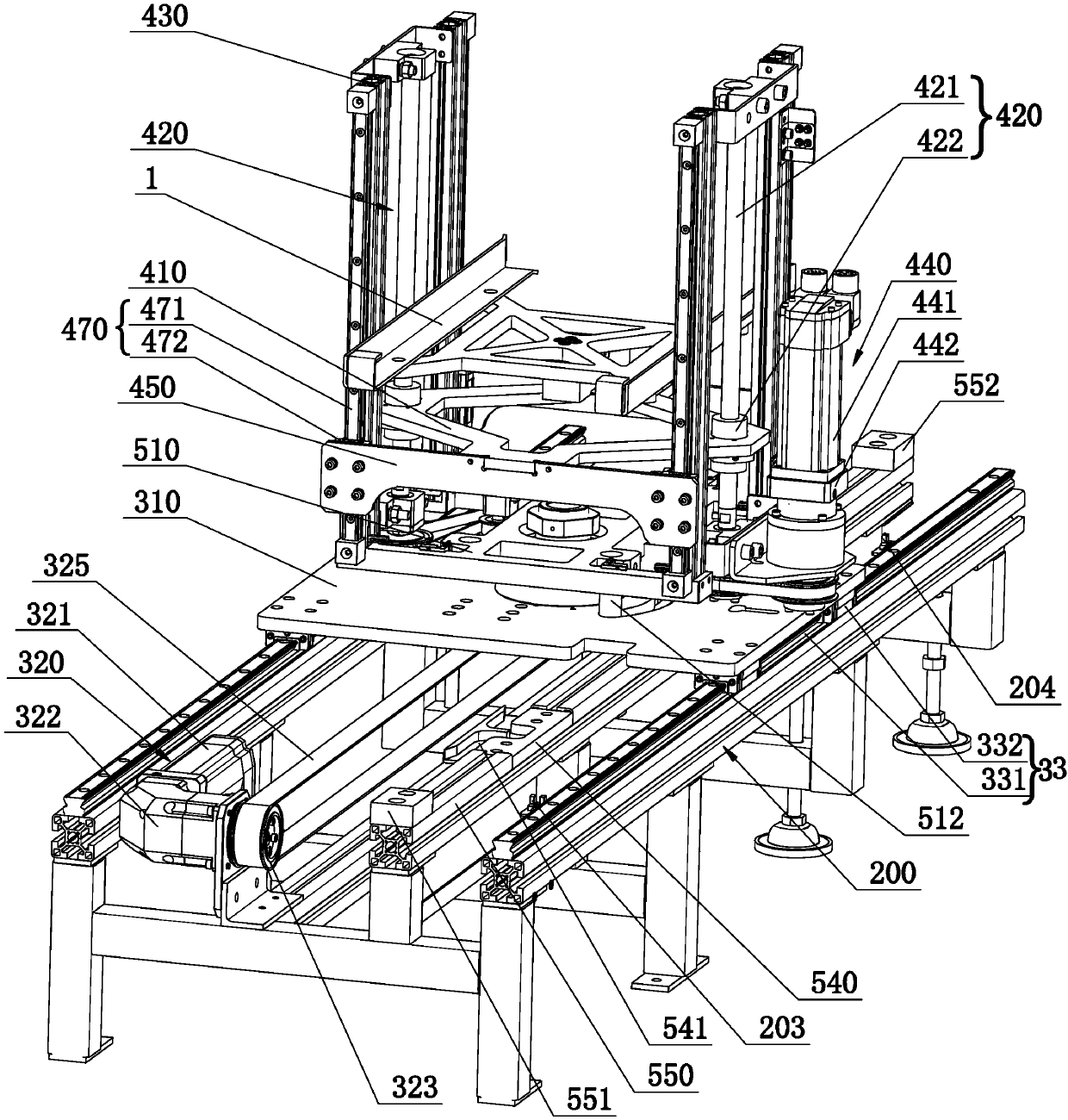

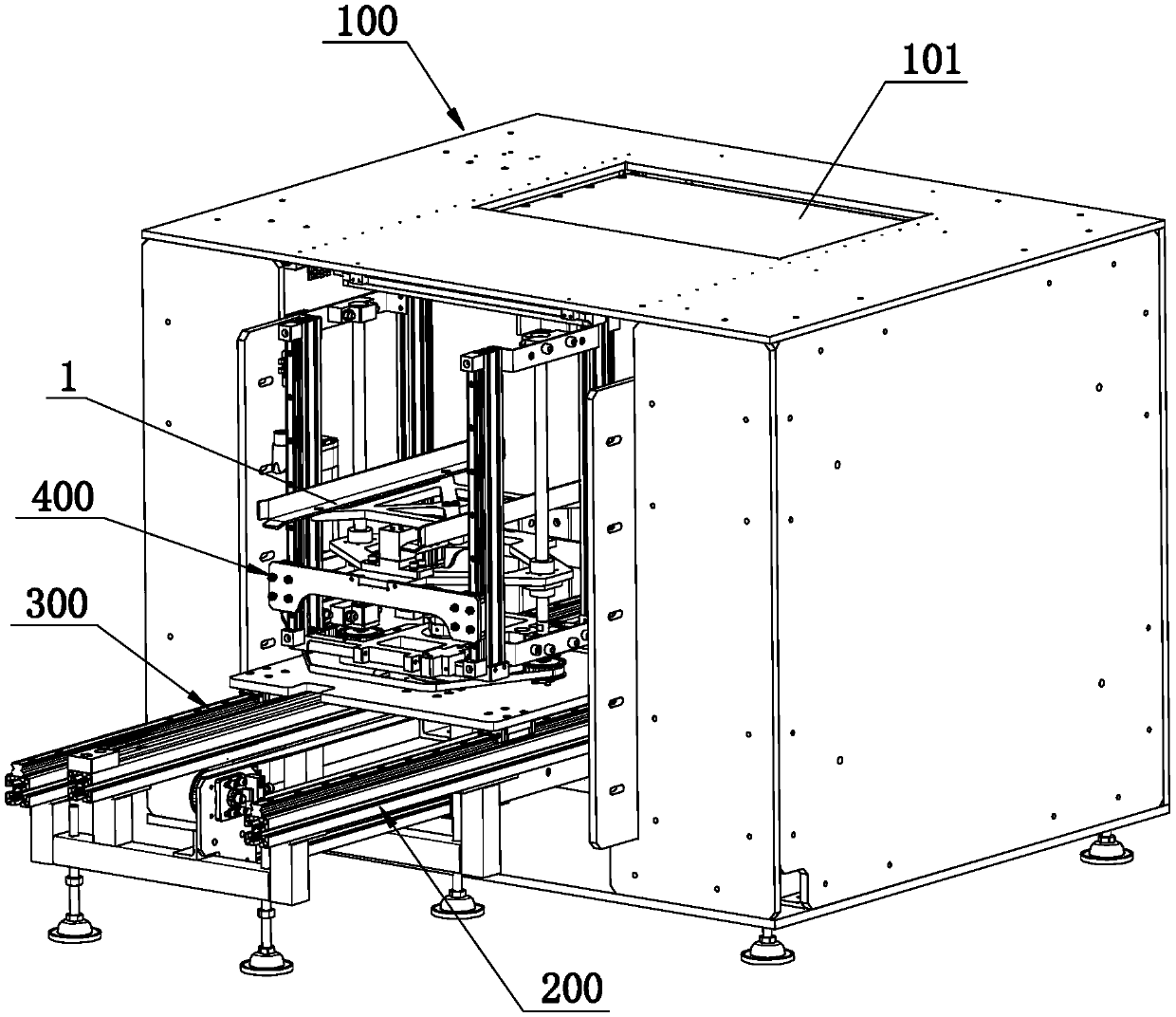

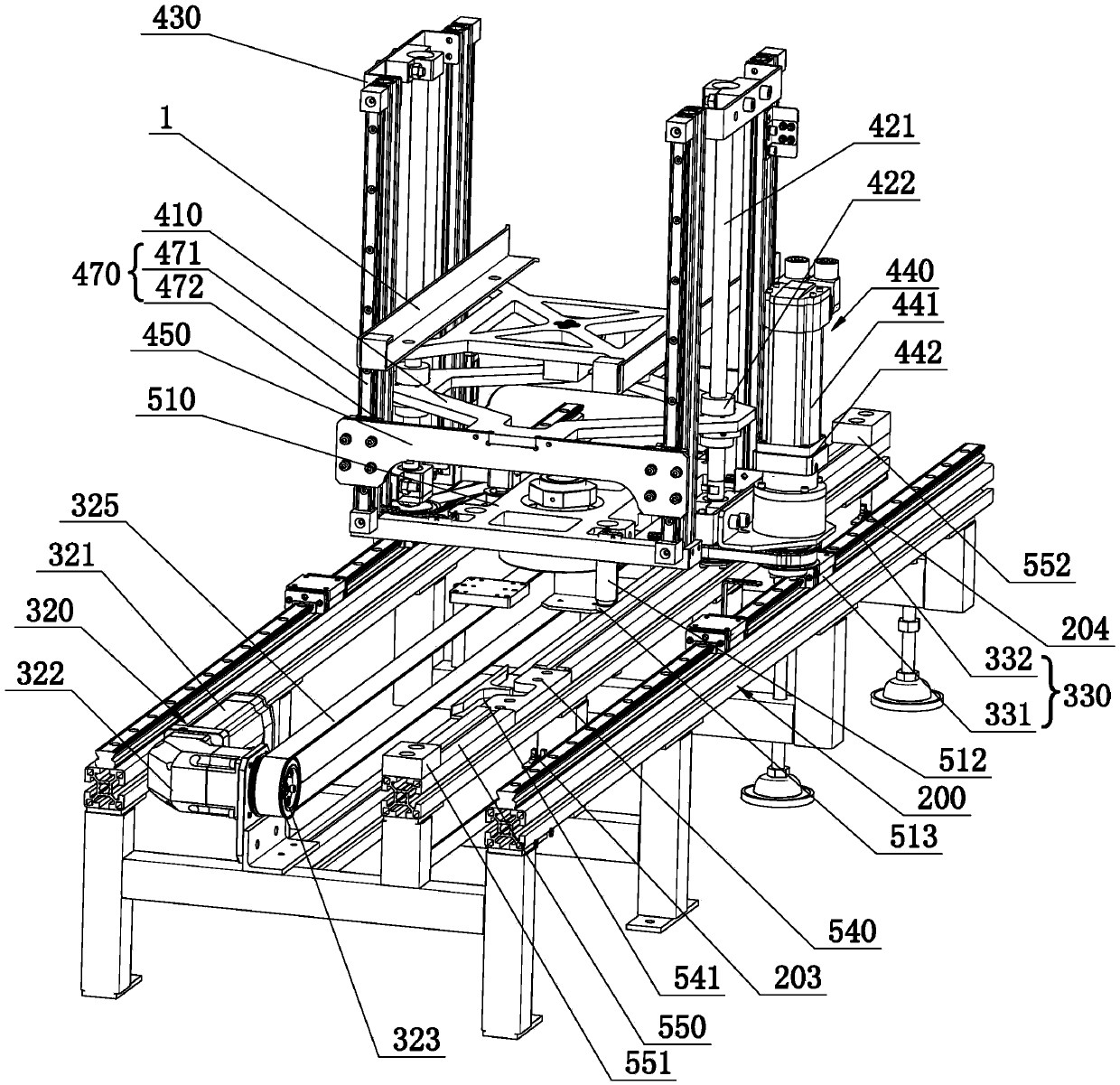

[0040] Embodiment one: if Figure 1-Figure 3 Shown, a kind of conveying device of fully automatic safe deposit box viewing table, comprises

[0041] The conveying chassis 200, the conveying chassis 200 is installed through the safe deposit box and the protective shell 100 outside the warehouse;

[0042] Horizontal translation mechanism 300, the horizontal translation mechanism 300 is arranged on the conveying chassis 200, and the transverse translation mechanism 300 is used for horizontally transporting the storage box along the conveying chassis 200 to the protective shell 100 outside the warehouse or retracting it into the safe deposit box warehouse;

[0043] Vertical elevating mechanism 400, vertical elevating mechanism 400 is arranged on the lateral translation mechanism 300, and vertical elevating mechanism 400 is provided with the installation frame 1 that is used to place storage box, and vertical elevating mechanism 400 is used for storage box is sent to The access op...

Embodiment 2

[0045] Embodiment two, other structures are identical with embodiment one, and its difference is: as Figure 2 to Figure 5 As shown, the lateral translation mechanism 300 includes a horizontal sliding bottom plate 310, a horizontal driving assembly 320, and two sets of first sliding assemblies 330 composed of first guide rails 331 and first sliders 332. One end of the horizontal sliding bottom plate 310 passes through a set of first sliding assemblies. The sliding assembly 330 is connected with the conveying chassis 200, the other end of the horizontal sliding bottom plate 310 is connected with the conveying chassis 200 through another set of first sliding assemblies 330, the horizontal sliding bottom plate 310 is connected with the horizontal driving assembly 320, and the horizontal driving assembly 320 drives the horizontal The sliding bottom plate 310 reciprocates laterally and horizontally along the conveying chassis 200 through the first sliding assembly 330;

[0046] The...

Embodiment 3

[0053] Embodiment 3, other structures are the same as Embodiment 2, the difference is that: the conveying chassis 200 is provided with a first limit protection mechanism, and the first limit protection mechanism includes a limit sensor sensing piece 202, a first limit sensor 203 and the second limit sensor 204, the limit sensor sensing piece 202 is vertically arranged on the lower bottom surface of the horizontal sliding base plate 310, and the front end of the conveying chassis 200 is provided with the first limit sensor 203, through which the limit sensor sensing piece 202 judges whether the lateral translation mechanism 300 has moved to the end of the conveying chassis 200, the rear end of the conveying chassis 200 is provided with a second limit sensor 204, and judges whether the transverse translation mechanism 300 is reset to the conveying chassis by sensing the limit sensor sensing piece 202 In the initial position of 200 , the limit sensor sensing piece 202 is located b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com