Overpressure preventing water outlet mechanism of warm water boiler

A water outlet mechanism and water boiler technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of not having an exhaust port, rupture of the inner tank, loss, etc., to prevent the pressure of the inner tank from being too large, and to achieve safe technical performance. , the effect of smooth water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

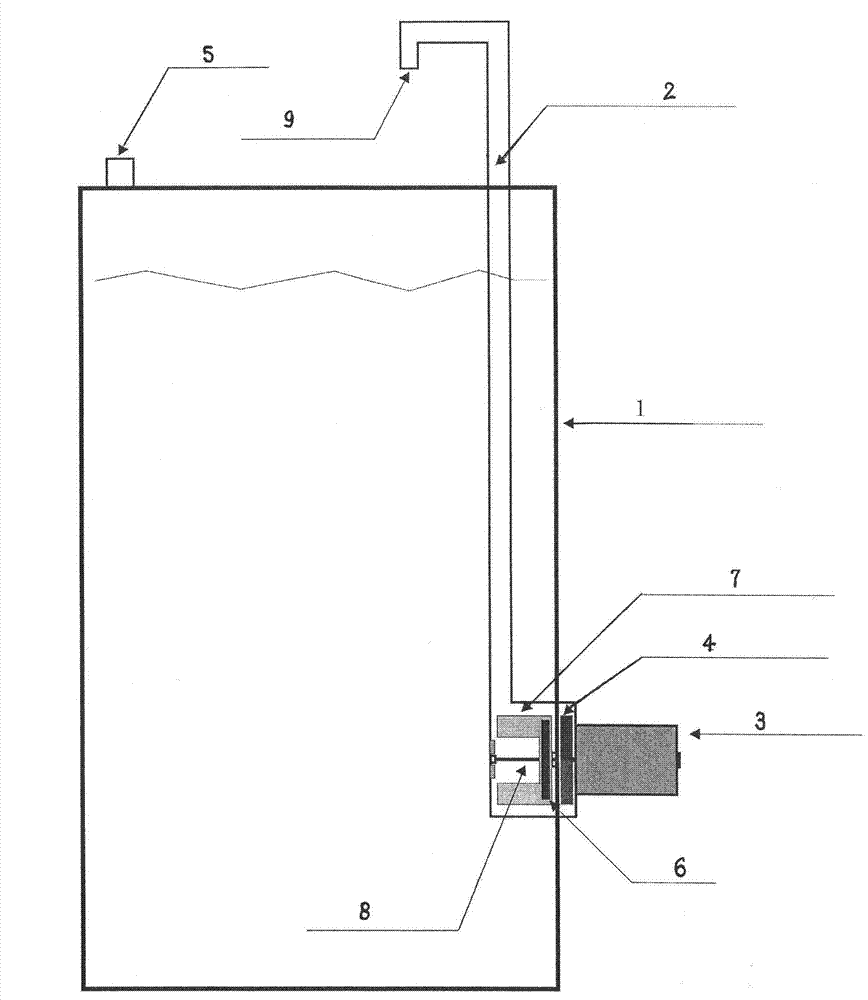

[0007] refer to figure 1 It can be seen that the anti-overpressure water outlet mechanism of the warm water boiler of the present invention includes an inner tank 1 and a water outlet pipe 2, and a water outlet motor 3 (connected without a shaft) is installed outside the side of the inner tank 1. An active magnetic material 4 is installed on the motor shaft; a passive metal material 6 is installed in the water outlet pipe 2 and opposite to the active magnetic material 4 (through the support rod 8), and a water outlet is installed on the passive metal material 6. The impeller 7 (that is, the passive metal material is equivalent to the base of the water outlet impeller 7). The upper part of the liner 1 is provided with an exhaust port 5 .

[0008] The active magnetic material 4 is NdFeB, and the passive metal material 6 is soft iron. NdFeB magnetic material, as the latest result of the development of rare earth permanent magnet materials, is called "magnet king" because of its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com