Storage and delivery management method of plate rolling steel

A management method and steel technology, applied in data processing applications, logistics, calculations, etc., can solve the problems of irregular steel placement, inability to judge scars, and difficulty in determining responsibility, and achieve convenient transactions, shortened warehousing time, and safety. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

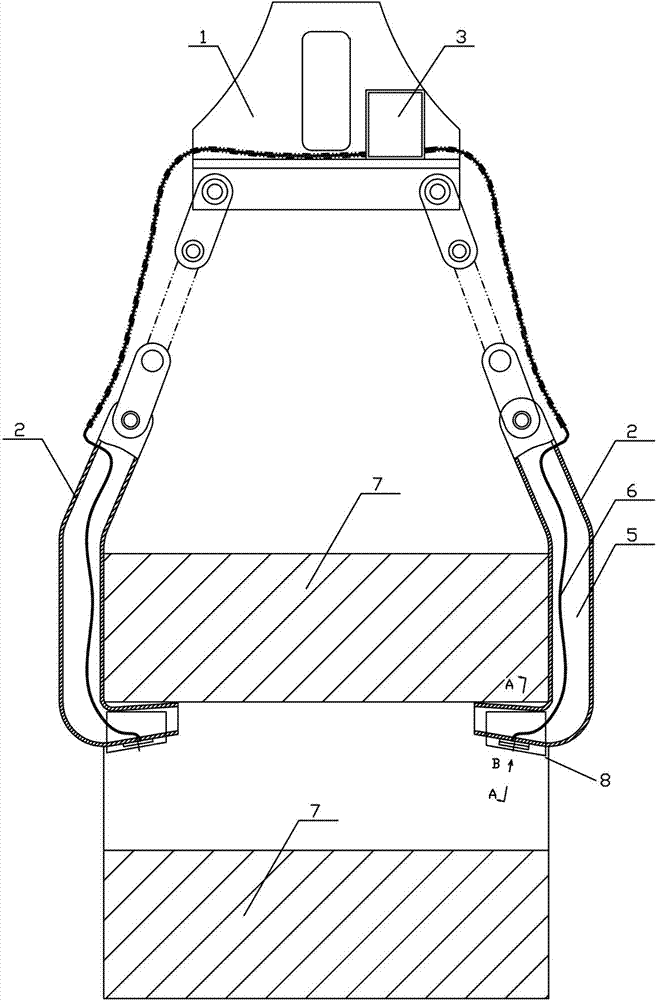

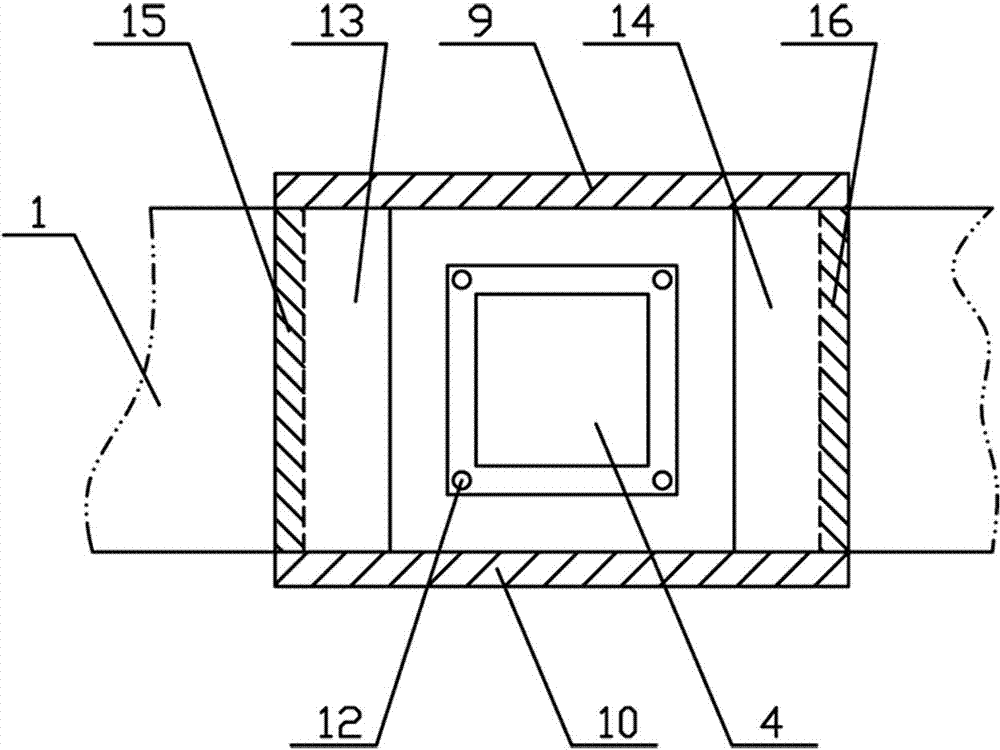

[0016] Embodiment 1, combining Figure 1 to Figure 3 , a warehouse-in and warehouse-out management method for steel coils, A. Before entering the warehouse, the information of each coil of steel is entered, so that the information of each coil of steel enters the electronic management system, and then the electronic management system generates information for each coil of steel. A serial number; B. Set the serial number of each coil of steel correspondingly on each coil of steel for identification; C. The electronic management system establishes a connection with the crane in the warehouse. The crane moves along the horizontal direction of the warehouse as a coordinate axis. The horizontal movement direction of the hook along the driving is another coordinate axis, and the direction of the hook’s rising or falling height relative to the driving is the third coordinate axis. The moving information of the driving is automatically entered into the electronic management system; D. ...

Embodiment 2

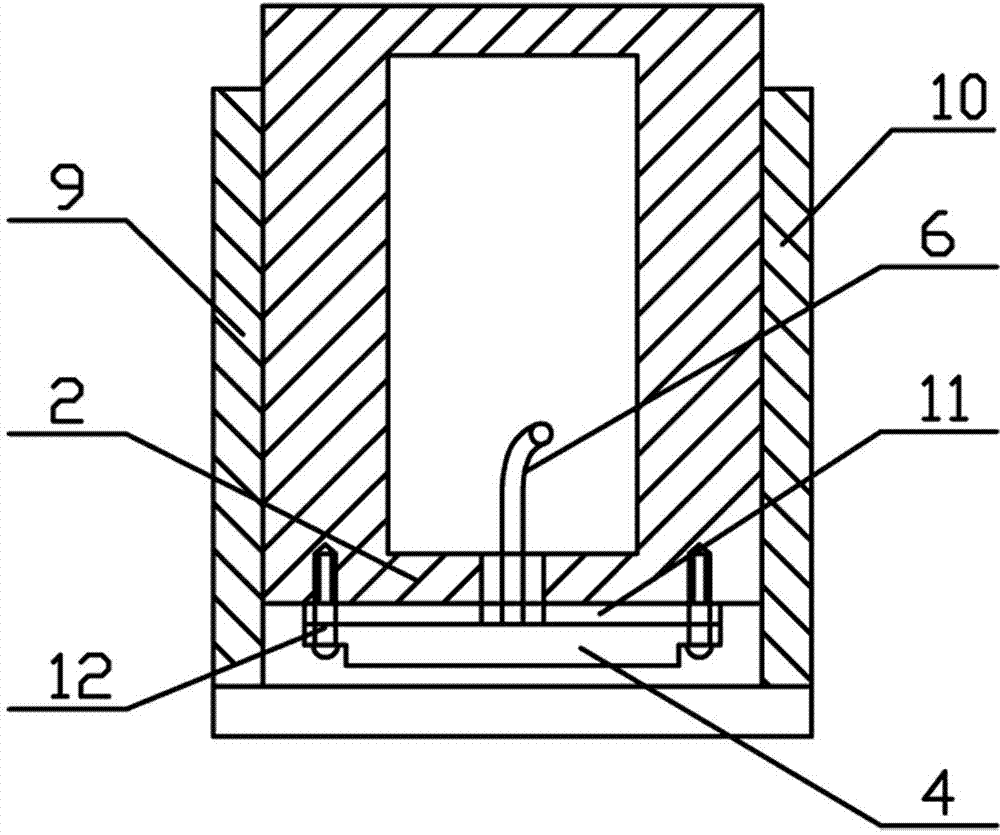

[0019] Example 2, combined with Figure 4 , the difference between embodiment 2 and example 1 is the hook. The hook of this embodiment includes a main body 1, two hook bodies 6, and two iron chains 5. The central position of the main body 1 is provided with a lifting hole 2, and the main body 1 is in the The horizontal direction is also provided with a plurality of adjustment holes 3, the upper end of the hook body 6 is connected with the iron chain 5, and the upper end of the iron chain 5 is connected with the main body 1, when the interval between the two hook bodies 6 is to be adjusted, the iron chain 5 The upper end can be hung in different adjustment holes. Symmetrically arranged between two hook bodies 6 。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com