Compressor

A compressor and compression mechanism technology, applied in the field of compressors, can solve problems such as temperature rise, and achieve the effects of preventing ozone layer destruction, suppressing temperature rise, and preventing global warming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

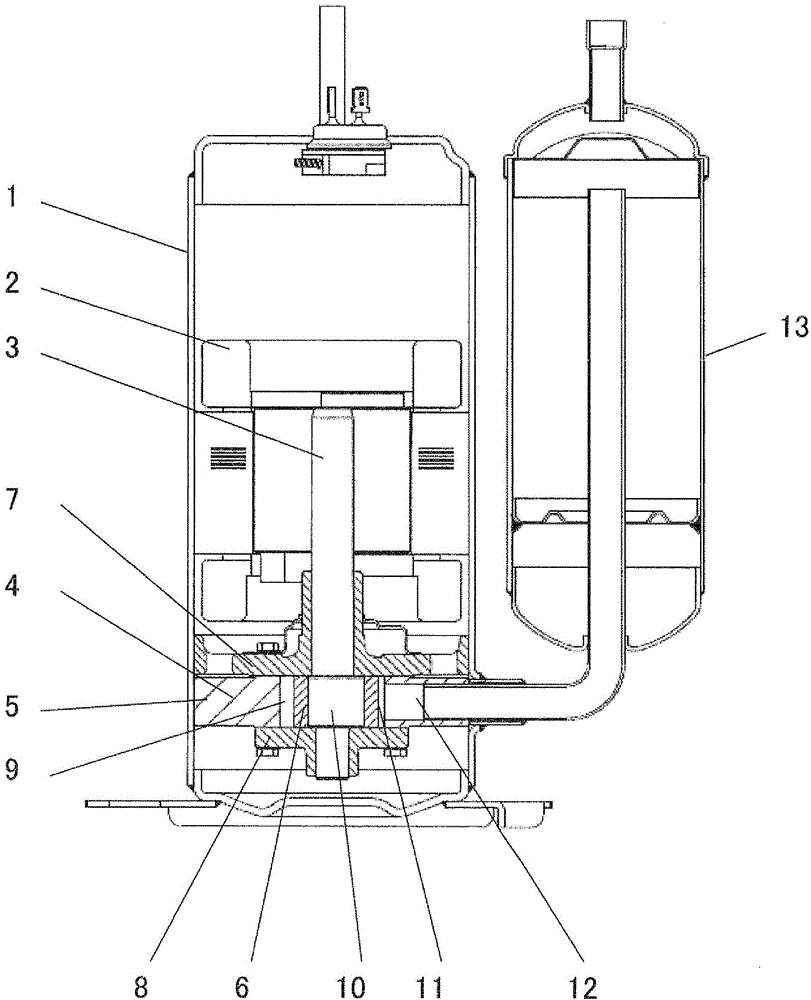

[0036] figure 1 It is a longitudinal sectional view of the overfeed (boost) type compressor in Embodiment 1 of the present invention.

[0037] exist figure 1 In the airtight container 1, an electric component 2 is accommodated. The compression mechanism unit 4 is driven by the drive shaft 3 in the vertical direction of the electric component 2 . The compression mechanism unit 4 is configured such that an upper bearing 7 and a lower bearing 8 sandwich a cylinder 5 , a rotary piston 6 , and vanes to form a compression chamber 9 and perform a compression operation. A crankshaft eccentric portion 10 integrally formed with the drive shaft 3 is accommodated in the cylinder 5 , and the rotary piston 6 is rotatably attached to the crankshaft eccentric portion 10 . In the cylinder 5 , vanes (not shown) are provided in contact with the rotary piston 6 , and are divided into a compression chamber 9 and a suction chamber 11 . A suction port 12 communicating with the suction chamber ...

Embodiment approach 2

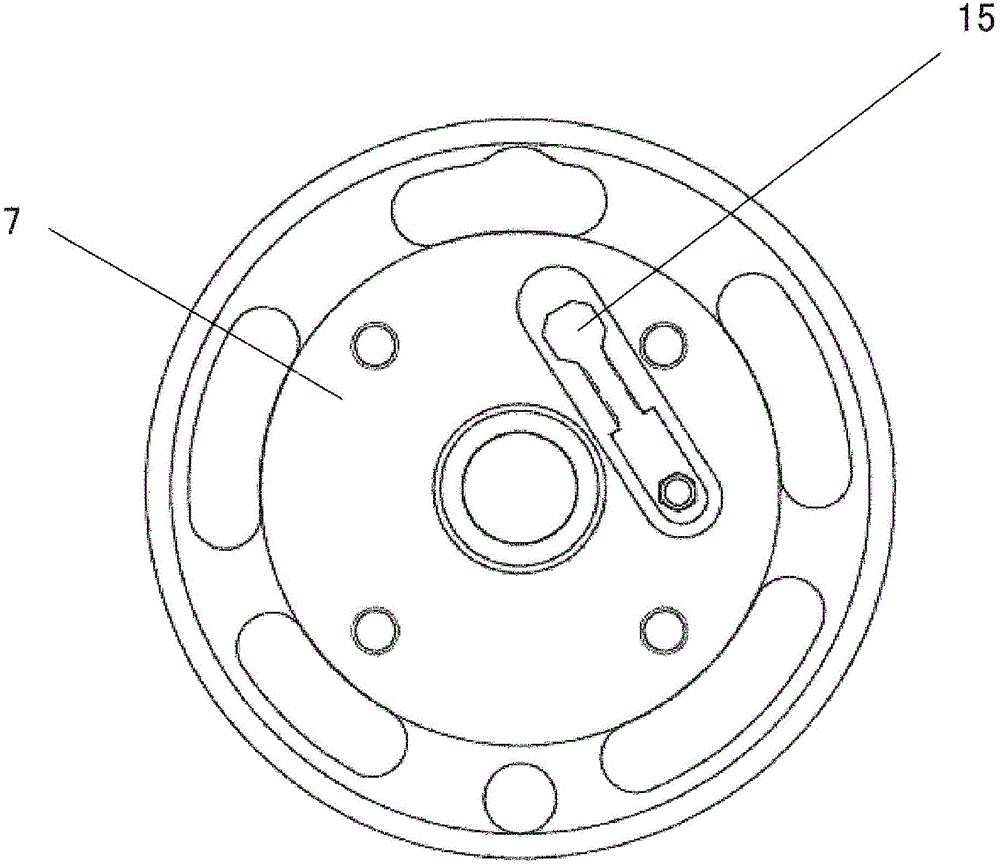

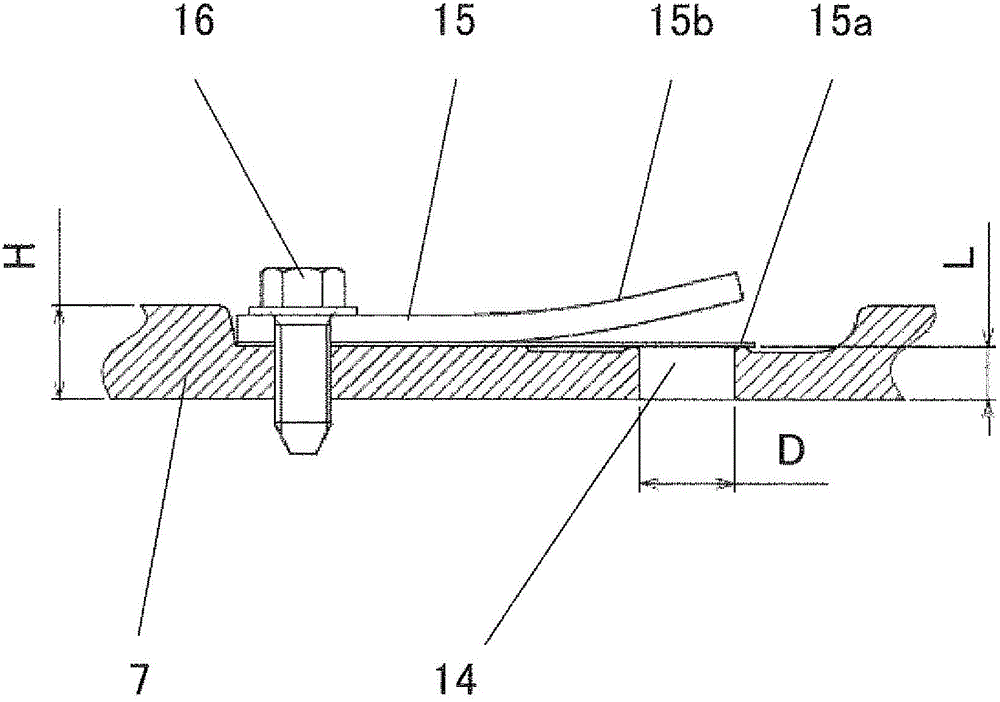

[0069] Figure 7 is a front view of the lower bearing 8 provided with the discharge check valve 15, Figure 8 It is a cross-sectional view of the lower bearing 8 taken along the longitudinal direction of the discharge check valve 15 . The discharge check valve 15 includes: a tongue valve 15 a for opening and closing the discharge port 14 ; and a tongue valve 15 b for restricting lift when the valve valve 15 a is opened.

[0070] In Embodiment 2, compared to Embodiment 1, the discharge check valve 15 is configured to move to the lower bearing 8 , and the same effects as those in Embodiment 1 can be obtained.

[0071] In addition, the lower bearing 8 is immersed in the lubricating oil accumulated in the lower part of the airtight container 1, so the noise generated by the discharge check valve 15 is attenuated by the lubricating oil, and it is difficult to transmit to the outside of the compressor, so a low-noise compressor can be provided. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com