Radiation-emitting semiconductor body, method for producing a radiation-emitting semiconductor body, and radiation-emitting semiconductor component

A technology that emits radiation and semiconductors. It is applied in the direction of semiconductor devices, electrical solid devices, and printed circuits assembled with electrical components. It can solve problems such as time-consuming and achieve the effect of rapid manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Elements that are the same, of the same type or have the same effect are provided with the same reference symbols in the figures. The drawings and the dimensional ratios of the elements described in the drawings to each other cannot be regarded as being to scale. Conversely, individual elements, in particular layer thicknesses, can be shown exaggerated for better visibility and / or for better understanding.

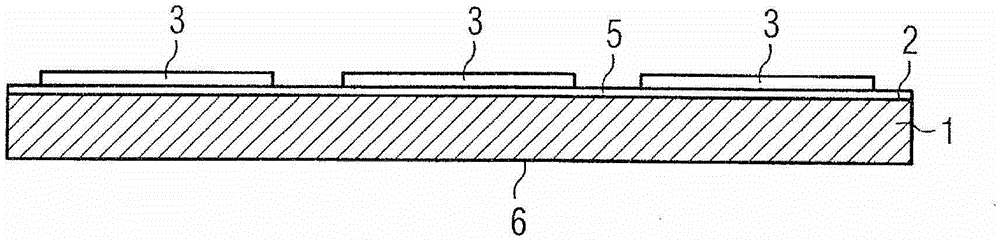

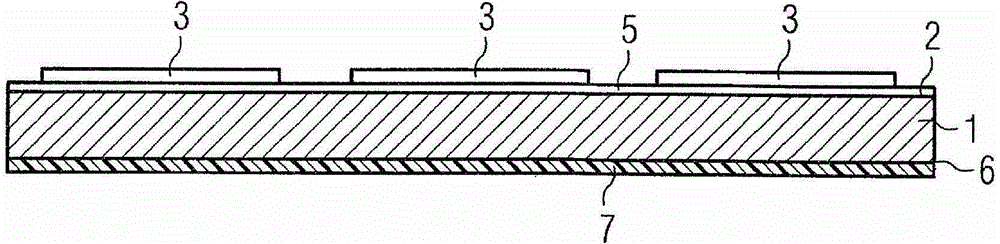

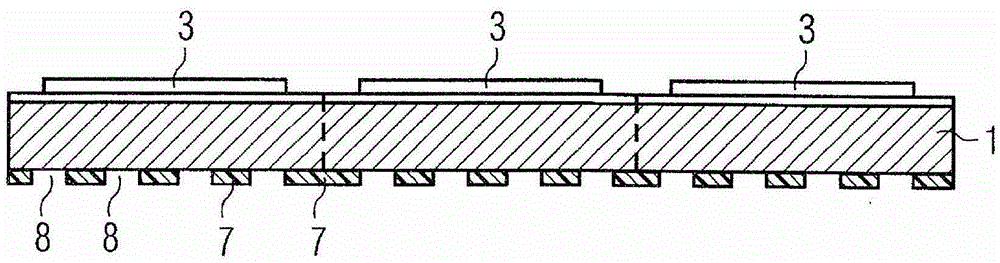

[0054] Figure 1A A carrier layer 1 is shown, on whose first main side 2 an epitaxial semiconductor layer sequence 3 is arranged. The carrier layer 1 mechanically stabilizes the semiconductor layer sequence 3 . The epitaxial semiconductor layer sequence 3 has now been structured in chip regions, each chip region then being part of the finished semiconductor body. The epitaxial semiconductor layer sequence 3 has an active region 4 suitable for generating electromagnetic radiation (in Figures 1A to 1G not shown).

[0055] Particularly preferably, the further laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com