Quick-changing type jaw vice

A quick-change, vise technology, applied in vices, manufacturing tools, etc., can solve the problems of inconvenient use, insufficient clamping or releasing of workpieces, and relatively large screw application, so as to achieve firm clamping of workpieces, Quick and easy action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

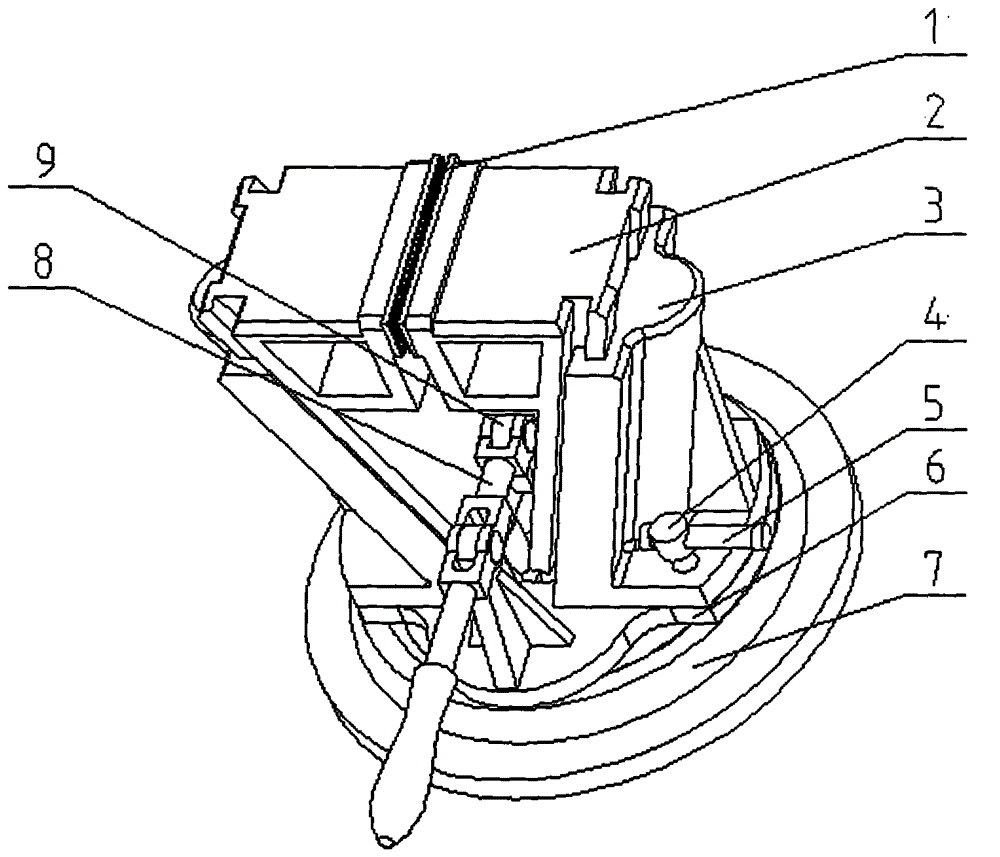

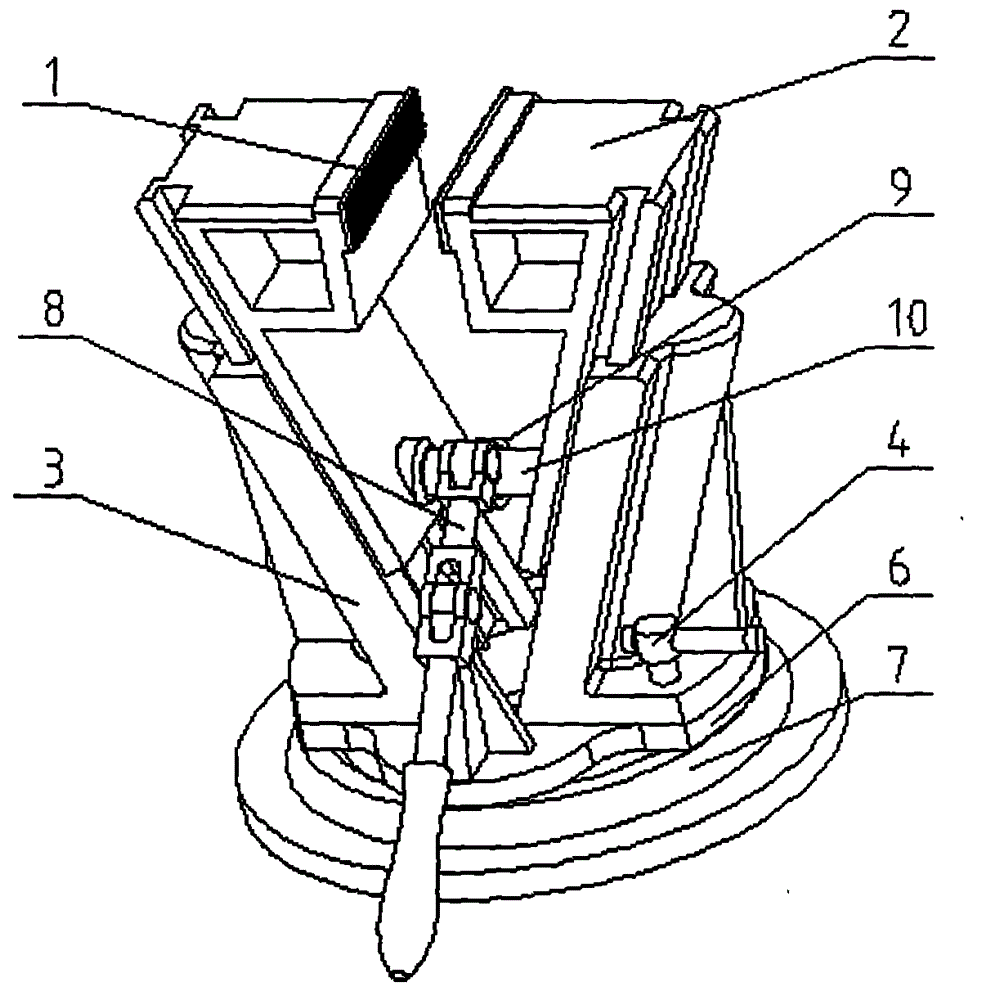

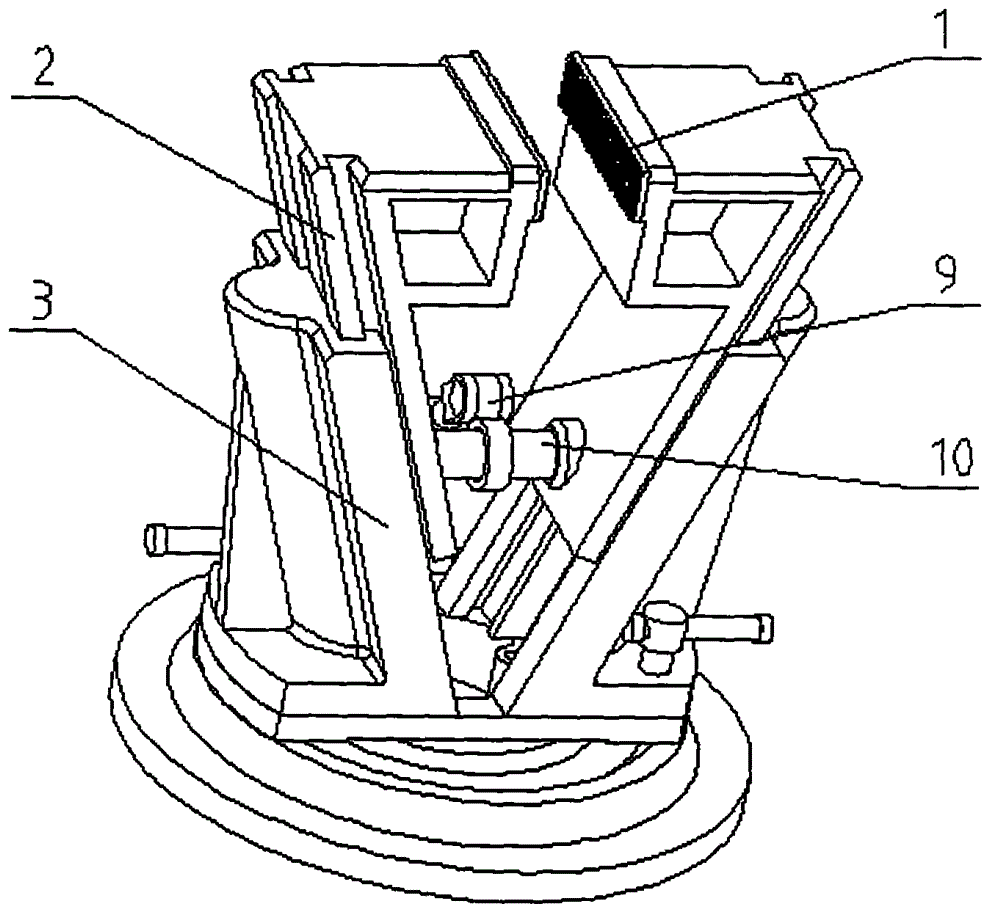

[0021] figure 1 It is a closed state axonometric view of the embodiment of the present invention; figure 2 It is an axonometric view of an expanded state of an embodiment of the present invention; image 3 It is an axonometric view of the rear side of the unfolded state of the embodiment of the present invention; image 3 It is a bottom sectional view of an embodiment of the present invention; Figure 5 It is a sectional view of the chute seat of the embodiment of the present invention.

[0022] Such as Figure 1-Figure 3 As shown, the quick-change vise includes a chute seat 3, a support plate 6 and a base 7, the support plate 6 is arranged on the base 7, and the support plate bottom is provided with a positioning plate 11 (such as Figure 4 shown), the left and right two chute seats 3 are arranged on the support plate 7, and movable jaws 2 are respectively arranged on it, and a spring 12 is arranged in the space formed by the movable jaws 2 and the chute seat 3 (such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com