Even-gear input shaft deep hole grinding system and grinding method thereof

A technology of input shaft and even-number gears, which is applied in deep-hole grinding system of even-number gear input shafts and in the field of grinding, which can solve the problems of difficult guarantee of grinding accuracy, poor cooling effect, high precision requirements, etc., so as to avoid burns on the grinding surface , wide clamping range, and the effect of ensuring positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

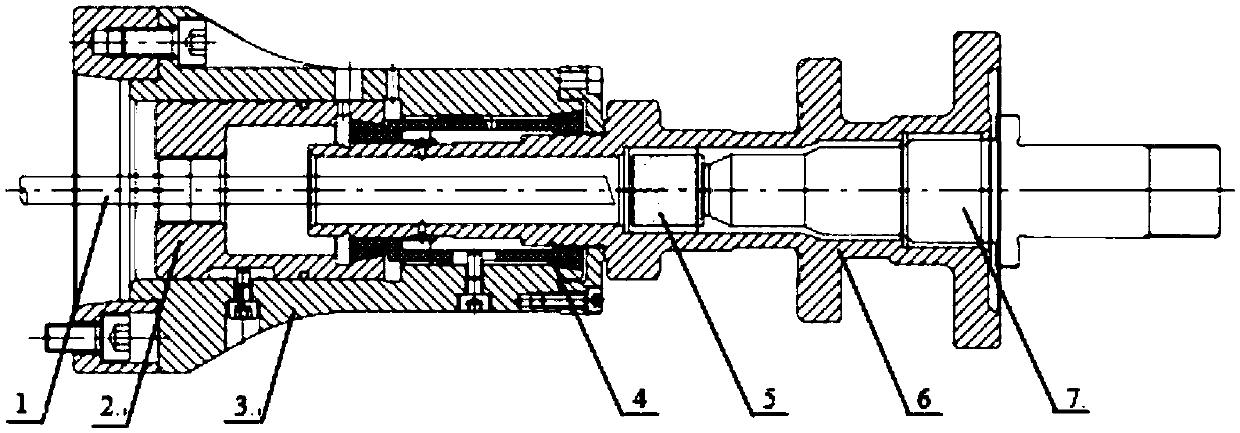

[0030] Such as figure 1 As shown, the even-numbered input shaft deep hole grinding system of the present invention consists of a clamp assembly and a processing assembly. The clamp assembly is composed of a jacket pull rod 2, a clamp body 3 and a self-centering elastic jacket 4; the processing assembly is composed of a cooling Liquid nozzle 1, grinding wheel 5 and high rigidity grinding rod 7 are formed.

[0031] One end of the jacket pull rod 2 is provided with a thread connected with the grinder, and the other end is provided with a tapered surface in contact with the self-centering elastic jacket 4 .

[0032] Both ends of the self-centering elastic jacket 4 have a tapered surface, one end is in contact with the jacket pull rod 2 , and the other end is in contact with the clamp body 3 .

[0033] The clamp body 3 is fixed with the grinding machine flange.

[0034] The self-centering elastic collet 4 is connected to the even-numbered gear input shaft, and the end face of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com