Safety product and method for printing anti-counterfeiting mark

A security product and marking technology, applied in the field of anti-counterfeiting, can solve the problems of restricting the feasibility of practical application, not using the same ink, inconvenient observation and identification, etc., and achieve the effect of improving the public anti-counterfeiting level, easy to observe, and easy to observe and identify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

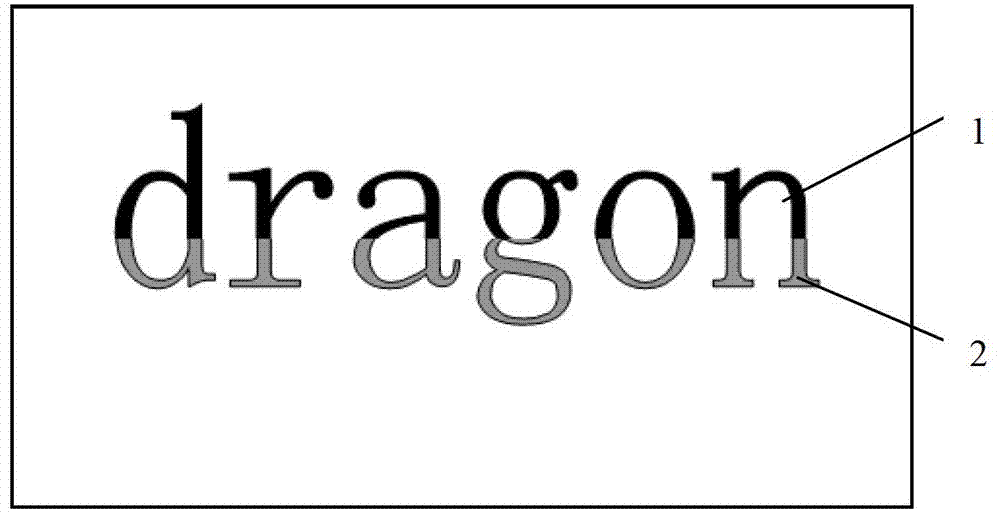

[0070] figure 1 It is a schematic diagram of an embodiment of the present invention, and the pattern is designed as the word "dragon", which is printed by engraved gravure printing. The upper half of the pattern, area 1, is printed with green / blue optical variable ink, and the lower half, area 2, is printed with green metallic effect ink.

[0071] Green metallic effect ink formula (weight%):

[0072]

[0073] The composition of the effect pigment in the above formula: 20-35% of the effect pigment coated with glass as the substrate, 50-70% of the effect pigment coated with mica as the substrate, and 50-70% of the effect pigment coated with alumina as the substrate 10%-30%, 0%-8% of the effect pigment coated with silica as the base material, the composition is based on the total mass of the effect pigment included in the ink, and the sum of the mass percentages of each composition reaches 100% %.

[0074] The preparation process of the ink is as follows: firstly, the binde...

Embodiment 2

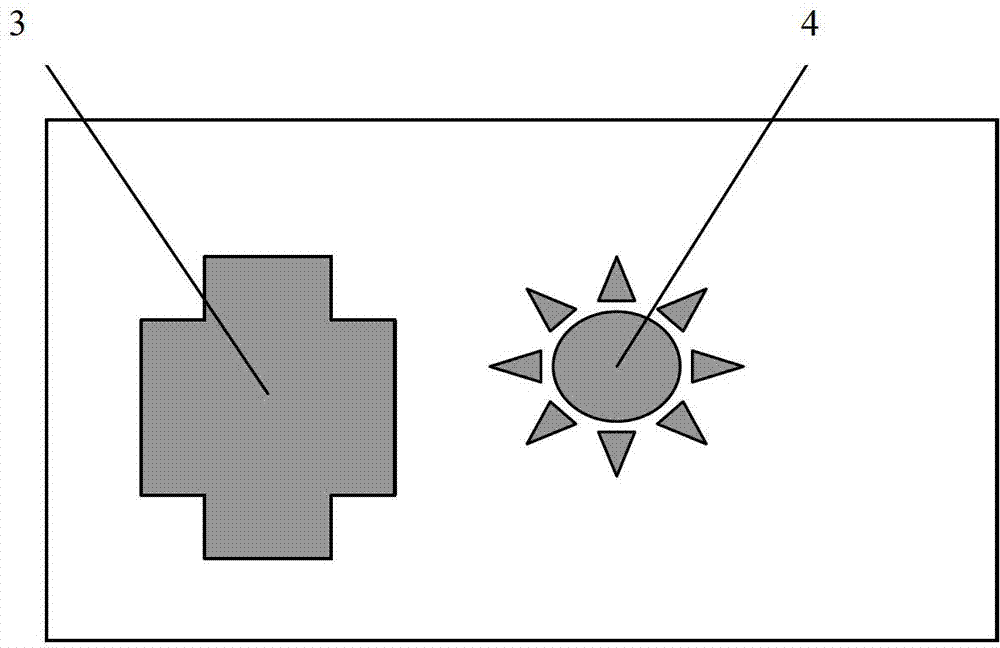

[0080] figure 2 is an embodiment of the present invention where two different patterns are printed using gravure printing. Area 3 is printed with gold / green optical variable ink, and area 4 is printed with gold metallic effect ink. Golden metallic effect ink formula (weight%):

[0081]

[0082] The composition of effect pigments in the above formula: 20-35% of effect pigments coated with glass as substrate, 20-35% of effect pigments coated with mica as substrate, 10% of effect pigments coated with alumina as substrate %-30%, 20%-35% of the effect pigment coated with silica as the substrate, the composition is based on the total mass of the effect pigment included in the ink, and the sum of the mass percentages of each composition reaches 100% .

[0083] The ink was produced in a similar manner to Example 1.

[0084] Basically, when viewed vertically, both area 3 and area 4 appear golden and have the same appearance effect; when viewed basically head-on, area 3 turns gr...

Embodiment 3

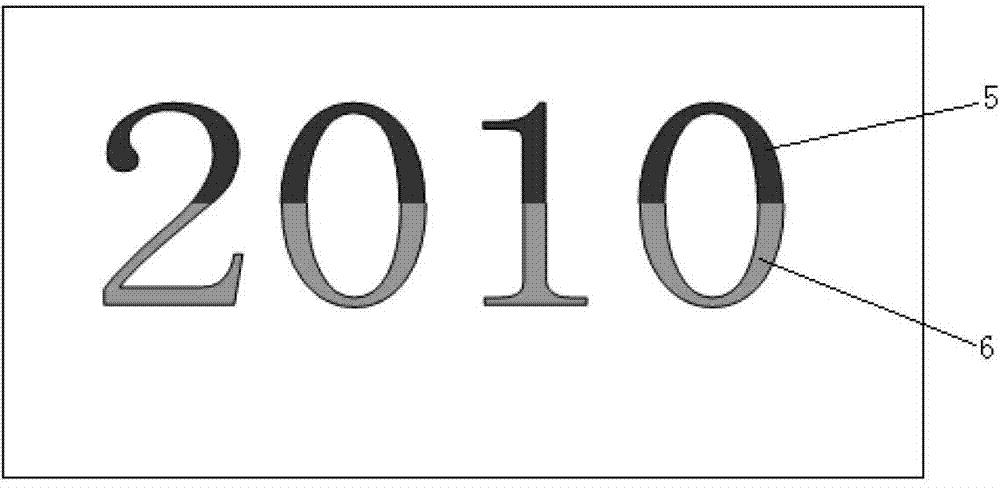

[0089] image 3 is an embodiment of the present invention using engraved gravure printing. Among them, area 5 uses green / blue light-changing ink, and area 6 uses green metal effect ink with infrared absorption effect.

[0090] Green metallic effect ink formula (weight%):

[0091]

[0092] The infrared regulator in the above formula is antimony-doped tin oxide coated with mica. The ink of this example was produced in a manner similar to that of Example 1.

[0093] Basically, when viewed vertically, both area 5 and area 6 appear green and have the same appearance effect; when viewed basically horizontally, area 5 turns blue, while the color of area 6 remains unchanged, forming a sharp color contrast between the two. The near-infrared spectral reflectance of area 5 and area 6 near 850nm is about 15%. When observed under infrared light, area 5 and area 6 show basically the same high gray value.

[0094] Table 3 shows the difference in parameters of the two ink printing area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com