Swirl plasma ignition nozzle

A plasma ignition and swirling technology, which is used in jet propulsion devices, gas turbine devices, machines/engines, etc., can solve the problems of low ignition success rate, affecting the effective diameter of ignition, arc inclination, etc. Effective ignition diameter and the effect of preventing blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

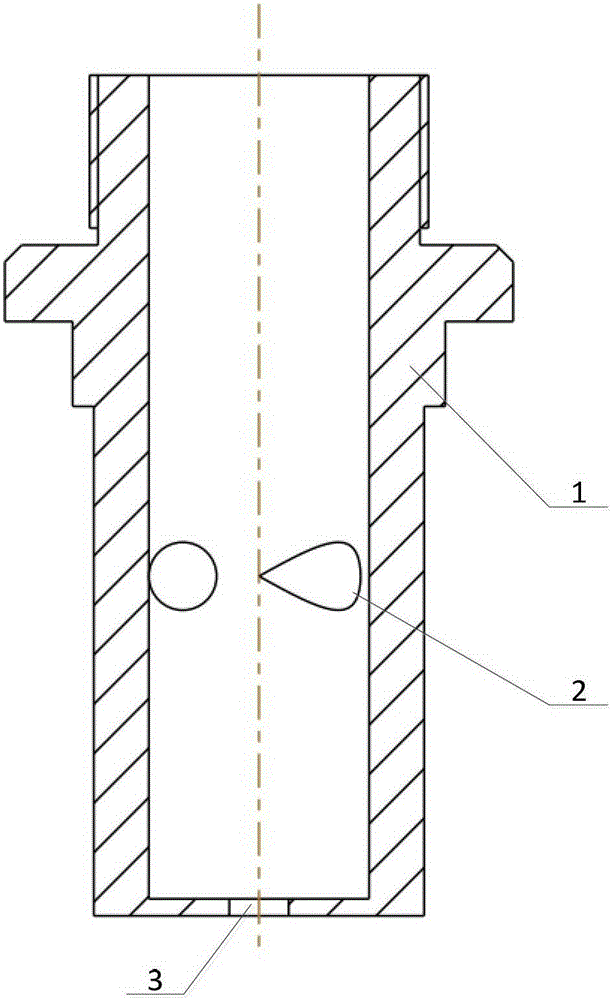

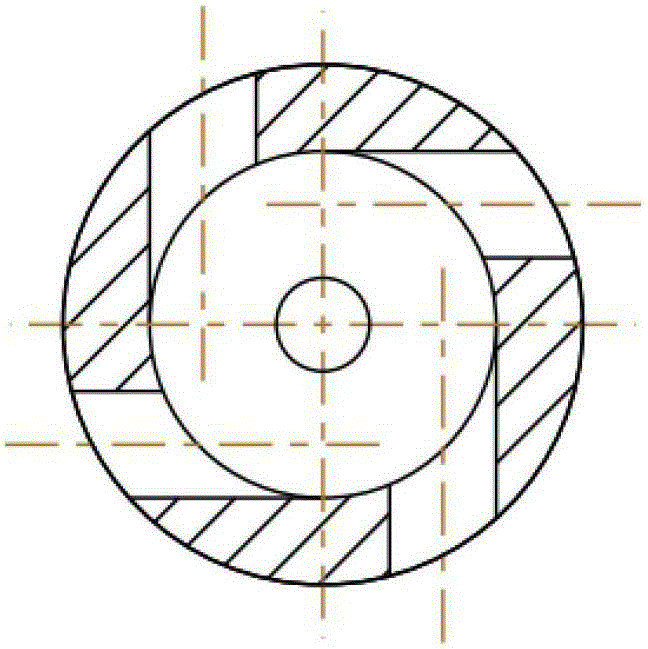

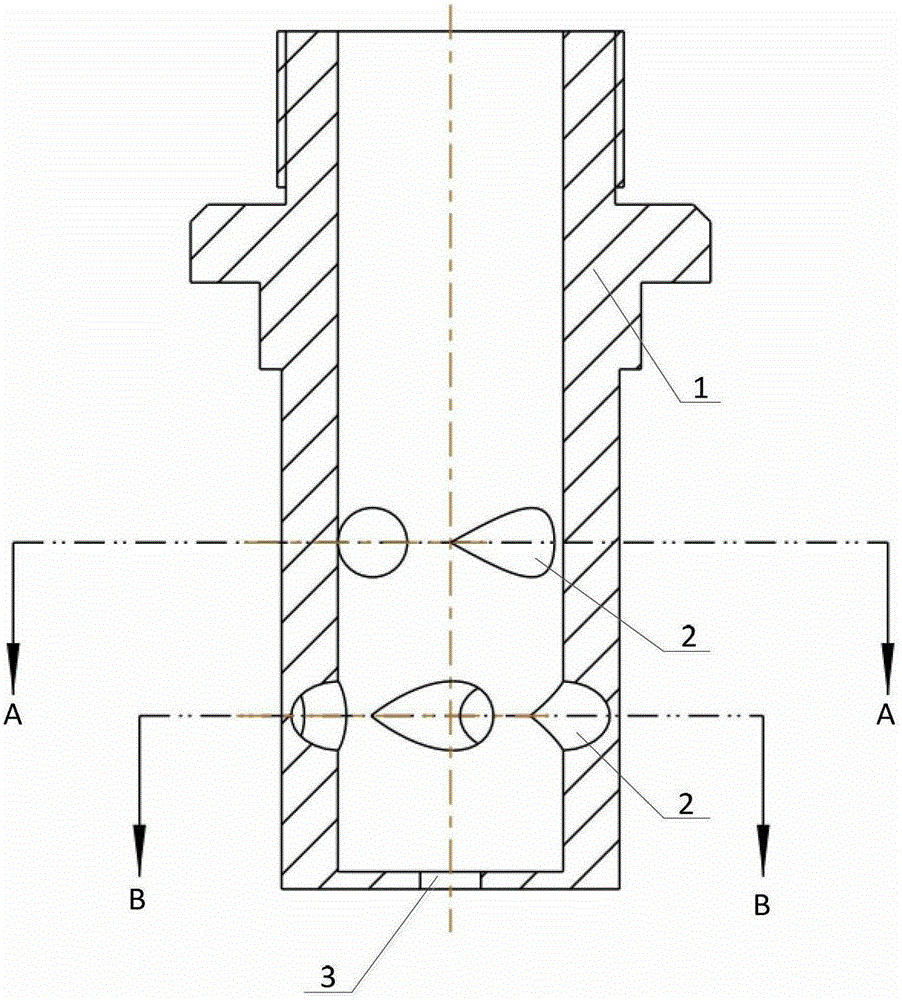

[0017] to combine Figure 1-5 , There is an air swirl hole 2 at the electric nozzle 1 of the plasma igniter. Blow out, create a flame, and ignite the fuel. Among them, the swirl hole 2 is tangent to the inner diameter of the electric nozzle 1, so that the incoming air and the exiting plasma arc produce a swirl effect, enhance the rigidity of the arc, prevent it from being blown obliquely by the external air, ensure the effective diameter of the ignition, and improve the success of the ignition Rate.

[0018] The nozzle 1 of the plasma igniter is provided with a swirl hole 2, the air enters the cavity of the nozzle 1 through the swirl hole 2, and then the plasma arc generated between the nozzle 1 and the cathode is blown out through the outlet channel 3 to form a flame , to ignite the fuel. The swirl hole 2 is tangent to the inner diameter of the electric nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com