High-pressure pump

A technology for high-pressure pumps and pump components, applied in the field of high-pressure pumps, radial or in-line plunger pumps, can solve the problems of fluid dynamic characteristics deterioration, drive mechanism damage, friction increase, etc., to achieve improved rolling characteristics and fluid flow dynamic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

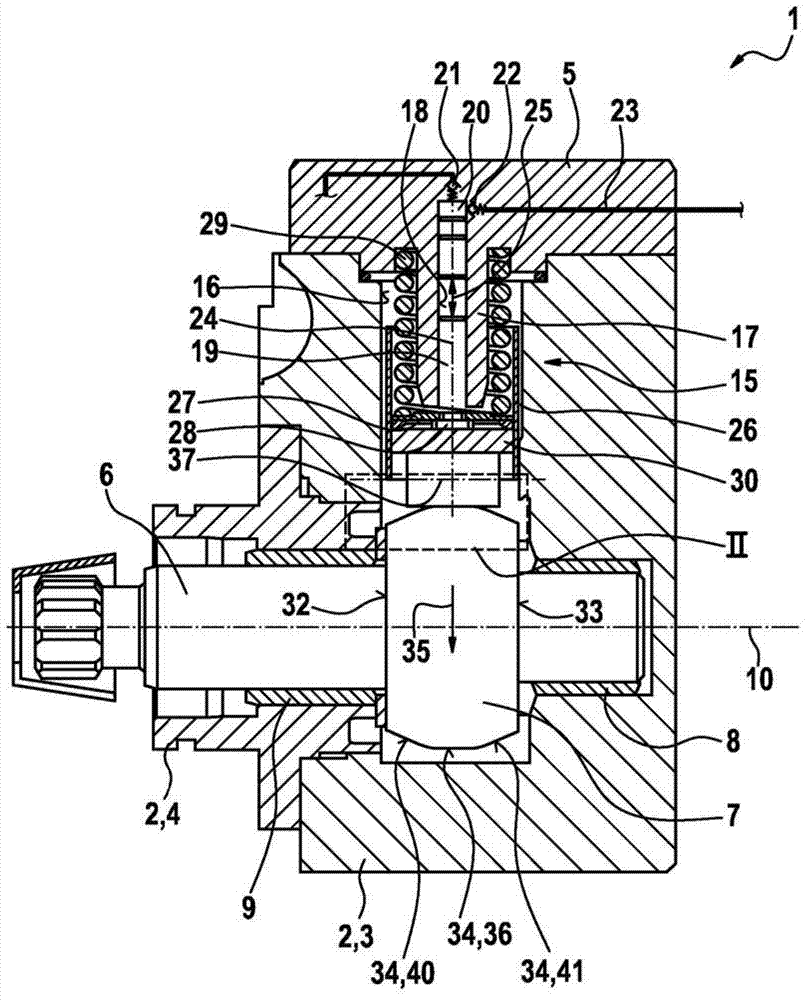

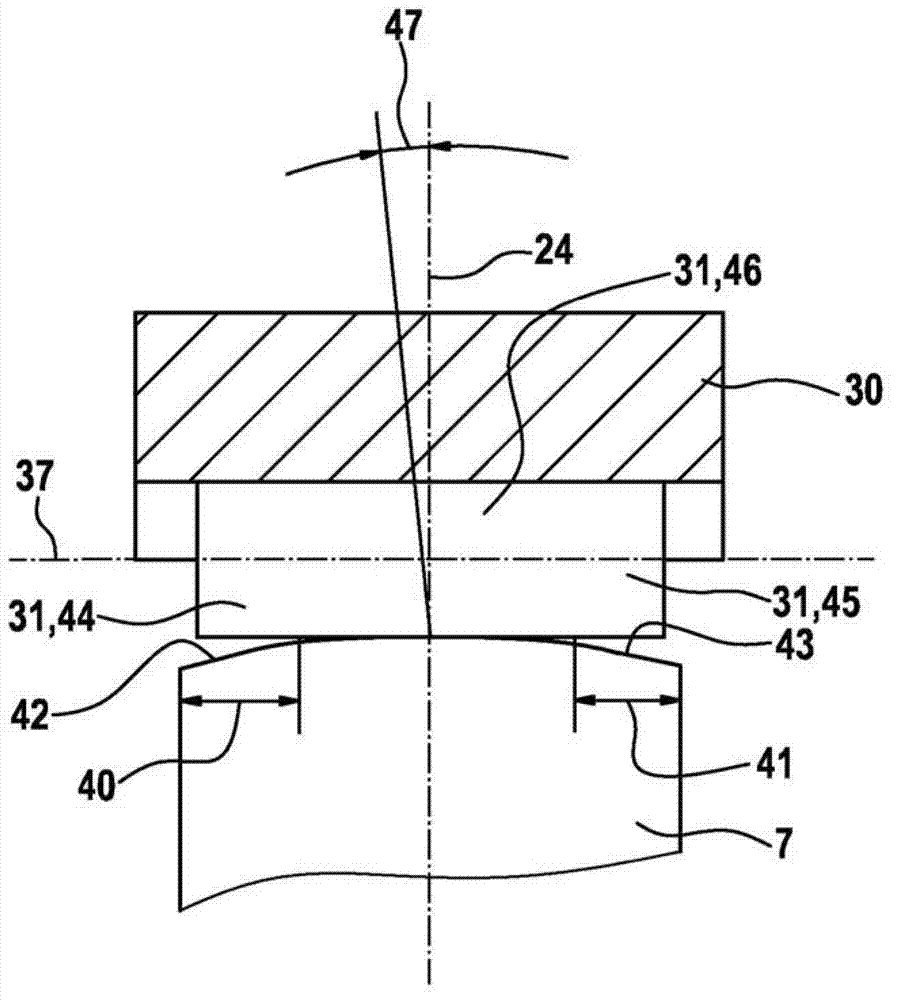

[0016] figure 1 A high-pressure pump 1 according to one embodiment of the present invention is shown in schematic axial section. In particular, the high-pressure pump 1 can be designed as a radial pump or as an in-line piston pump. The high-pressure pump 1 is particularly suitable as a fuel pump of a fuel injection system for an air-compressed self-igniting internal combustion engine. A preferred application of the high-pressure pump 1 is in fuel injection systems provided with a fuel distribution rail, a so-called common rail, which stores diesel fuel under high pressure. However, the high-pressure pump 1 according to the invention is also suitable for other applications.

[0017] The high-pressure pump 1 has a multi-part pump housing 2 . The pump housing 2 here comprises a housing part 3 and a flange 4 connected to the housing part 3 . Furthermore, a cylinder head 5 is provided, which is connected to the housing part 3 .

[0018] A drive shaft 6 is arranged in the pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com