Printing head

A printing head and printing material technology, which is applied in the field of printing head, can solve the problems that the printing head cannot be realized, and achieve the effect of meeting personalized, rich colors and meeting printing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

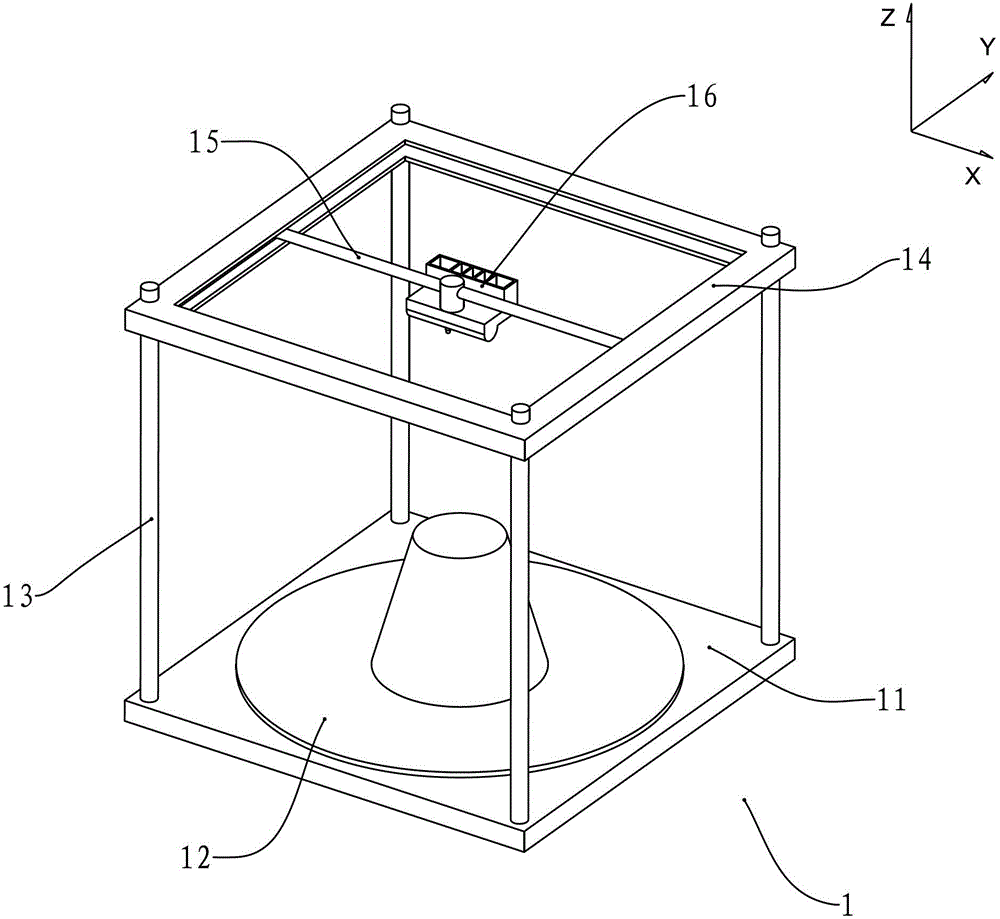

[0018] see figure 1 , the three-dimensional printing device 1 includes a bottom plate 11 and a forming seat 12 arranged on the bottom plate. Four screw rods 13 extend vertically upward from the bottom plate 11 , and the frame 14 is sleeved on the screw rods 13 and can be linearly fed along the Z direction along the screw rods 13 . A guide rod 15 is further provided on the frame 14, and the guide rod 15 can be linearly fed along the Y direction on the frame 14. The printing head 16 is sleeved on the guide rod 15, and can perform linear feeding along the X direction. Through the control of the 3D printing device 1 , the printing head 16 can be fed in the X, Y, and Z directions, thereby realizing the expected 3D printing.

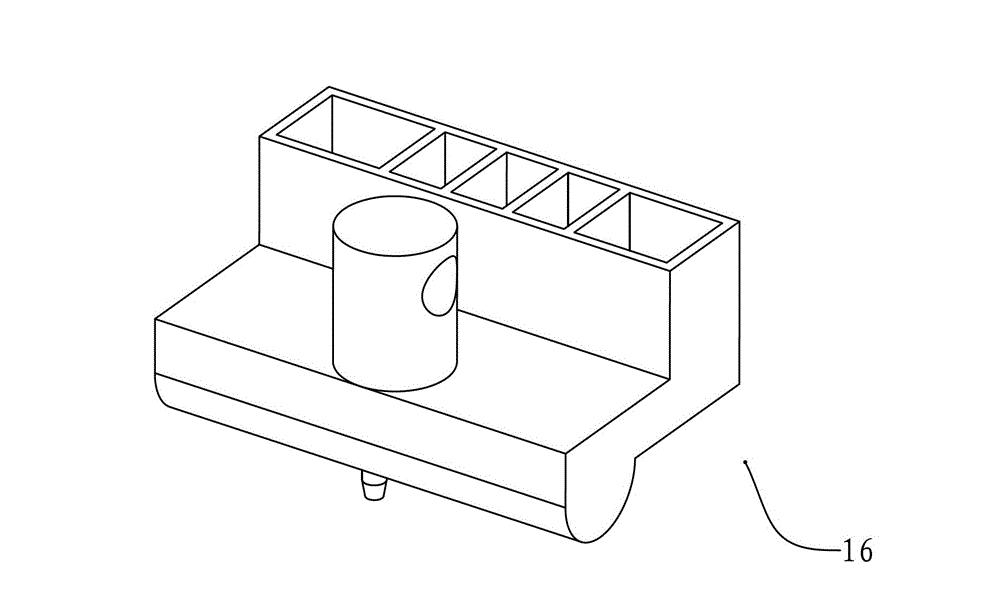

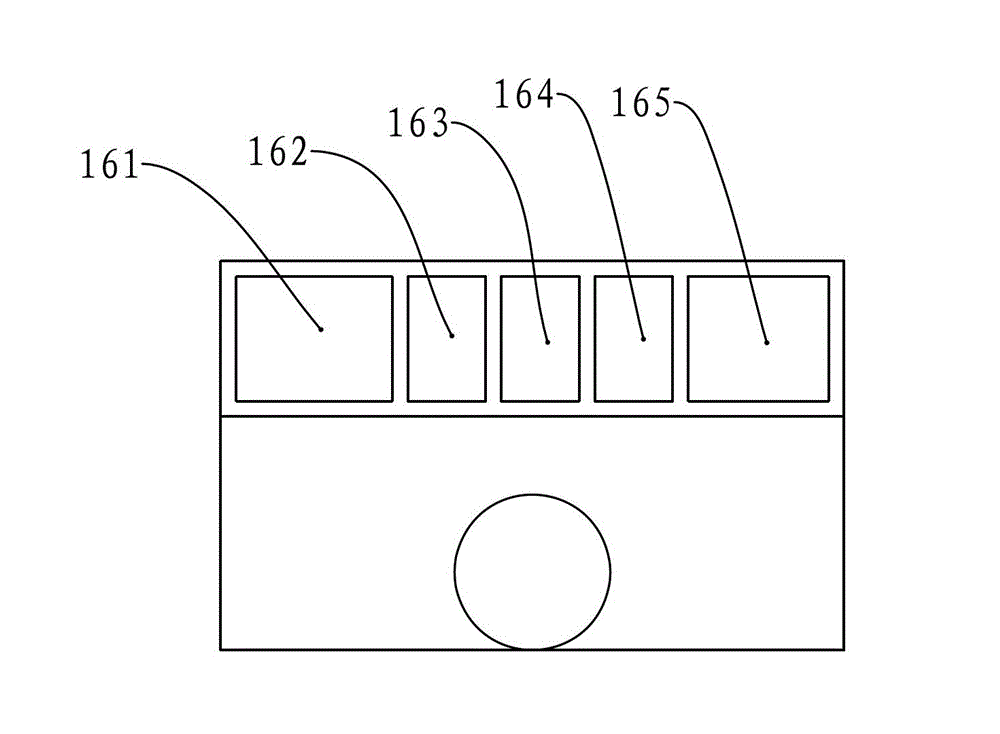

[0019] see figure 2 and image 3 , the print head 16 has four storage chambers (161, 162, 163, 164), and the storage chambers (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com