Bar feeding mechanism

A technology of feeding mechanism and bar, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of high production cost of enterprises, low work efficiency of workers, inconvenient operation of workers, etc., to achieve simple maintenance work, improve work efficiency, Simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

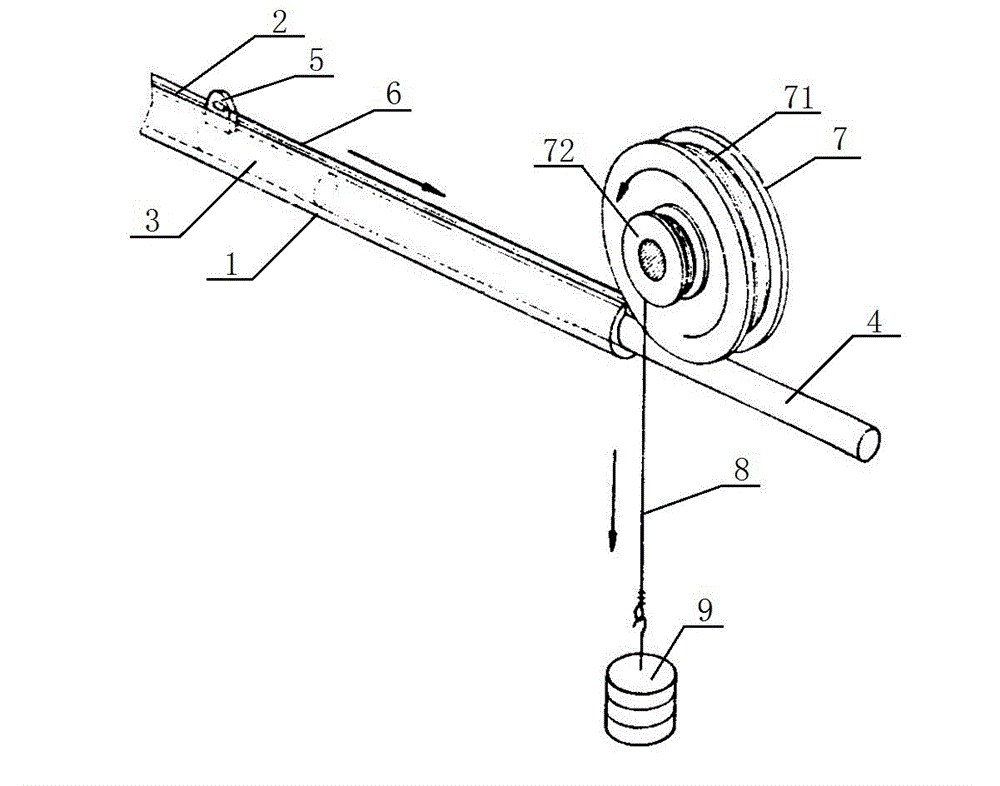

[0010] Such as figure 1 As shown, the present invention provides a kind of rod material feeding mechanism, comprises conduit 1 and duplex sheave 7, and the tube wall of conduit 1 is provided with longitudinal groove 2, and the rod material 4 of front and rear arrangement, pushing Rod 3 and push rod 3 are provided with lug plate 5, and push rod 3 is connected with drag cable 6 through lug plate 5; double sheave 7 is formed by coaxial connection of large sheave 71 and small sheave 72, and drag cable 6 winds Set on the big sheave 71, the small sheave 72 is connected with the weight 9 through the rope 8.

[0011] In this embodiment, the conduit 1 plays a good guiding role for the push rod 3 and the rod 4, the setting of the longitudinal groove 2 provides conditions for the movement of the push rod 3, and the setting of the double sheave 7 makes it possible to pull The cable 6 can be wound around the large sheave 71, thereby pulling the push rod 3 to move forward, thereby sending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com