Column-pile combined cover nut and use method thereof

A cap and column pile technology is applied in excavation, construction, infrastructure engineering and other directions, which can solve the problems of non-reusable and waste of columns, and achieve the effects of low cost, large social benefits and simple construction technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

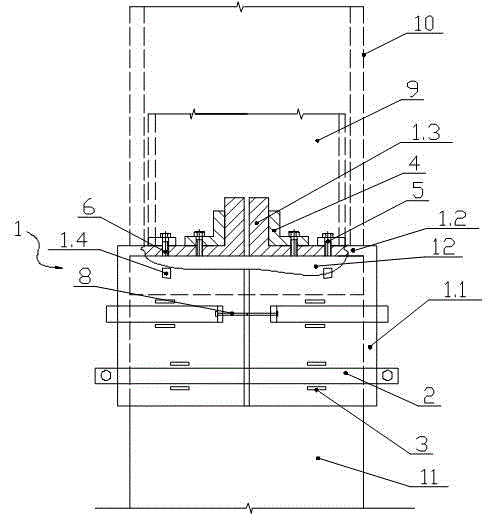

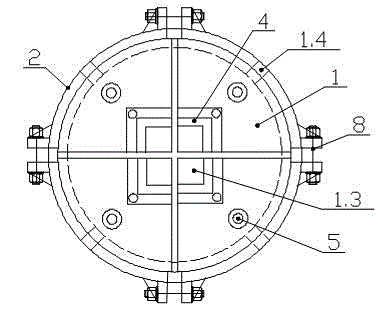

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

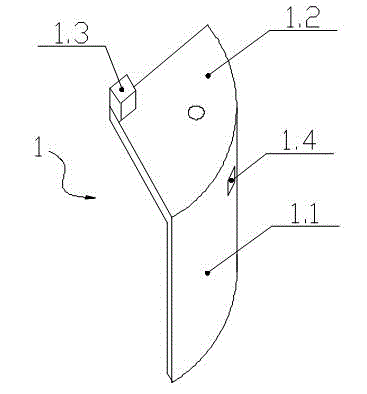

[0020] like figure 1 , 2 As shown in and 3, a pile combined cap is formed by splicing four identical cap petals 1, and gaps are left between the four cap petals 1 for easy locking. The body includes an arc-shaped sleeve body 1.1, a fan-shaped sleeve cover 1.2 and an upper protrusion 1.3, the fan-shaped sleeve cover is connected to the upper side of the arc-shaped sleeve body, and the upper protrusion is connected to the center of the fan-shaped sleeve cover; The arc-shaped sleeve body is provided with pin holes 1.4 for matching with the positioning pins on the metal cap on the top of the prestressed pipe pile, and one or more pin holes are provided. When only one pin hole is set, the pin hole is set at the middle part of the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com