Welding wire feeder with magnetic rotational speed sensor

A magnetic sensor and wire feeder technology, applied in the field of gears driven by motors in the U.S. Provisional No. 61/355,815 filed on the 7th, can solve the problems of reducing the efficiency of optical tachometers, malfunctioning of optical tachometers, and blocking LED light paths, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

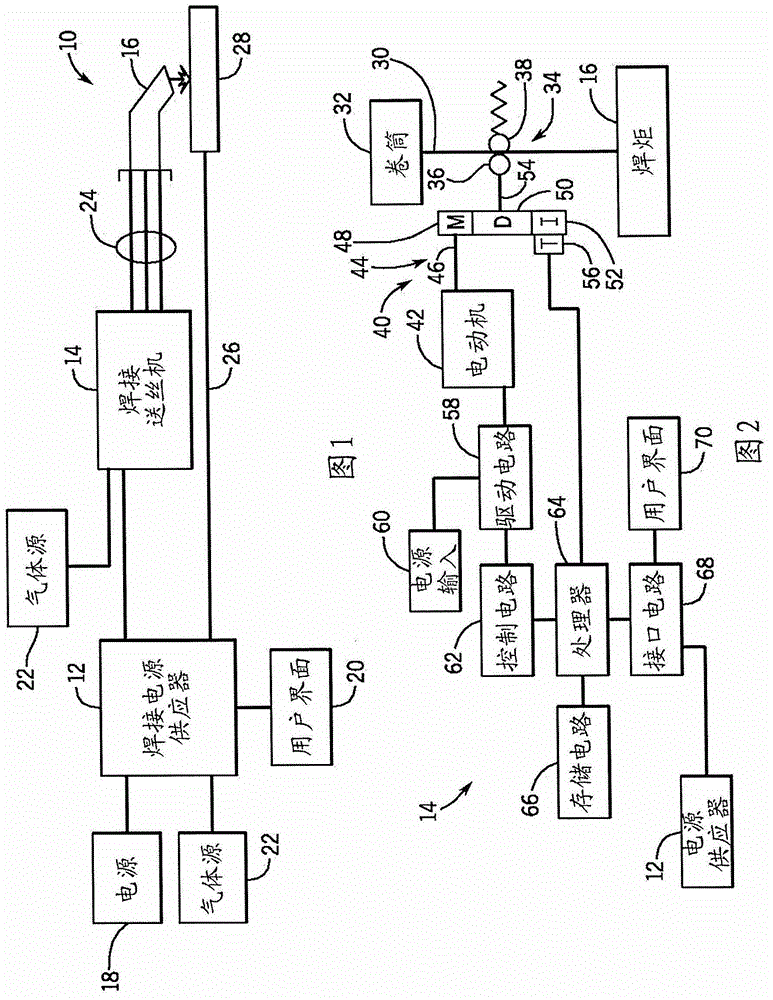

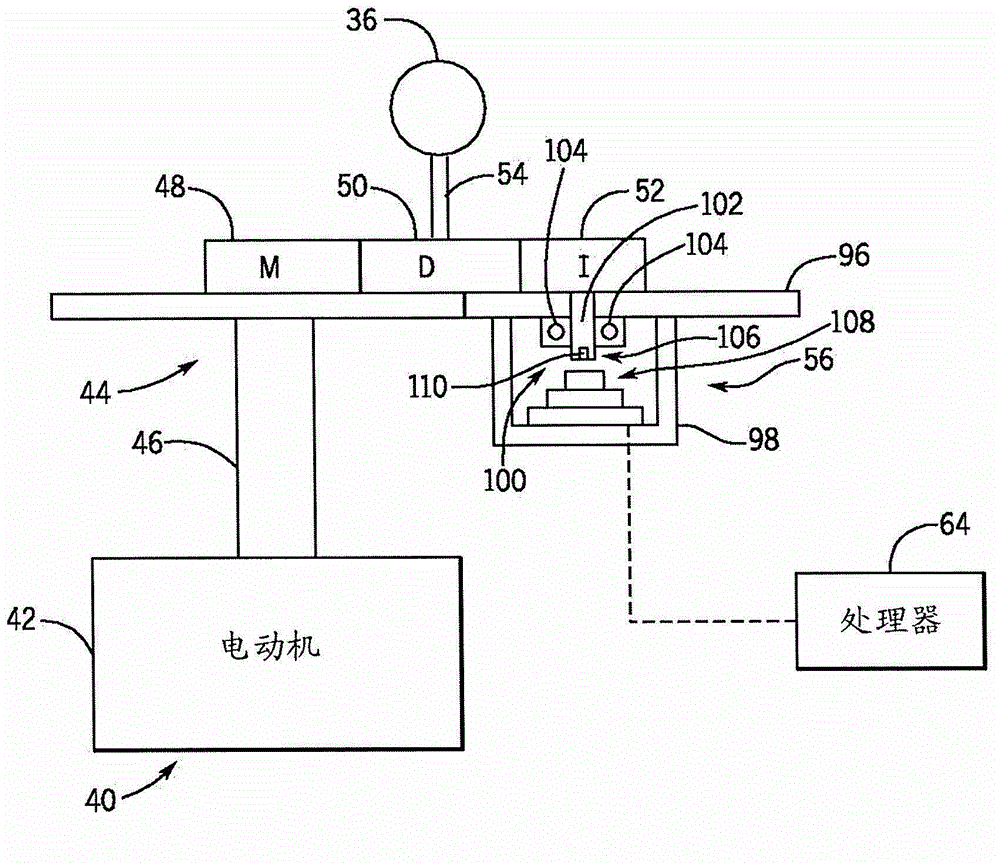

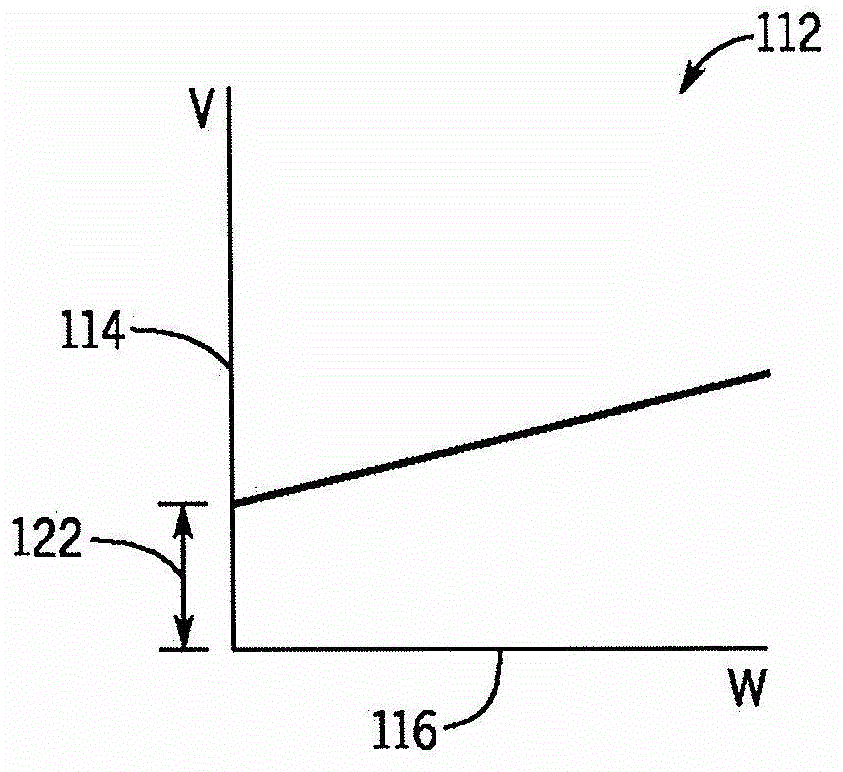

[0015] The present invention presents an exemplary embodiment of a welding wire feeder provided with a magnetic wire feed speed sensor. The welding wire feeder includes an electric motor configured to drive a drive roller to deliver welding wire to a welding torch. This motor also drives the idler gear, and the magnetic wire feed speed sensor measures the rotational speed of the idler gear by calculating its angular position and angular velocity. The rotational speed of another gear or rotating part of the system can be measured in a similar way. Specifically, in the described embodiment, angular position and angular velocity are measured with magnets located on a shaft connected to an idler gear and above an integrated circuit that responds to the shaft at regular intervals. The angular position is sampled. This angular position data can then be used to determine the angular velocity of the idler gear, which can be further converted into a wire feed speed measurement.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com