Laminate structure with embedded cavities and related method of manufacture

A form, integrated layer technology, applied in the direction of lamination, lamination device, lamination auxiliary operation, etc., can solve the problems of expensive, insufficient performance, complex and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

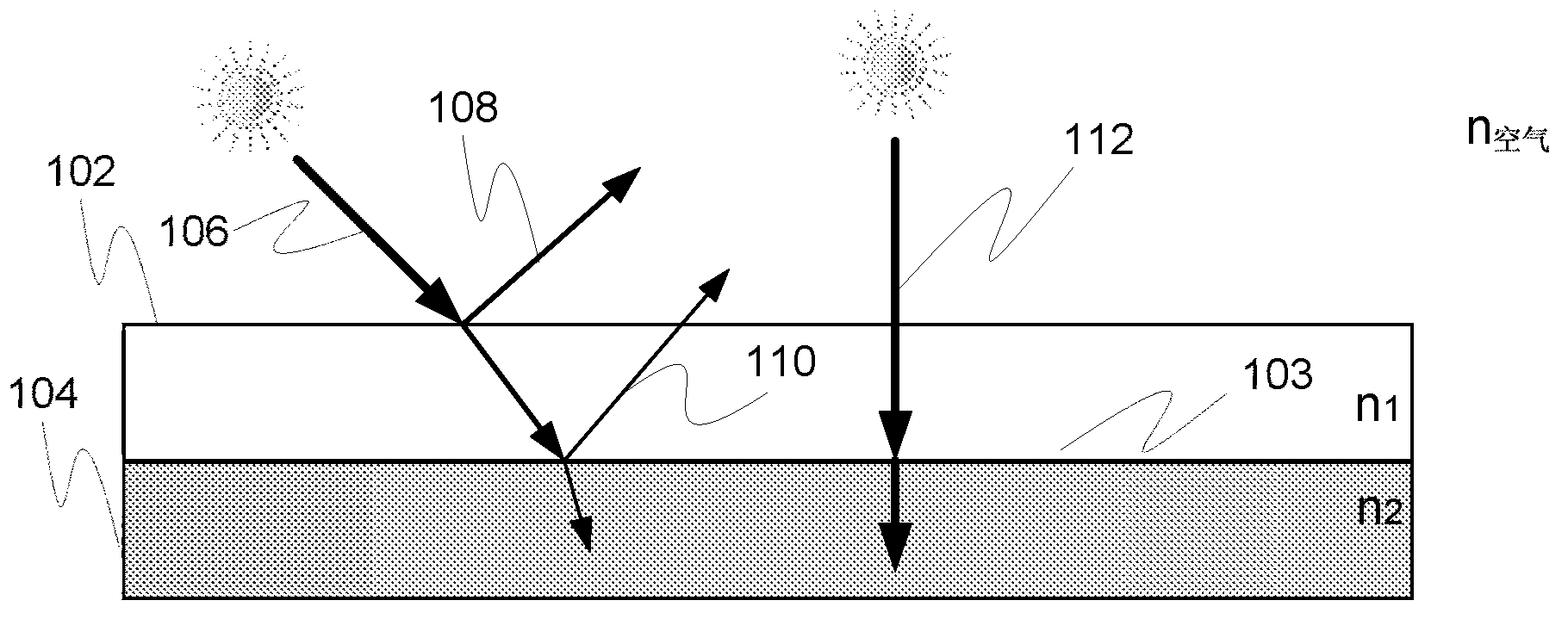

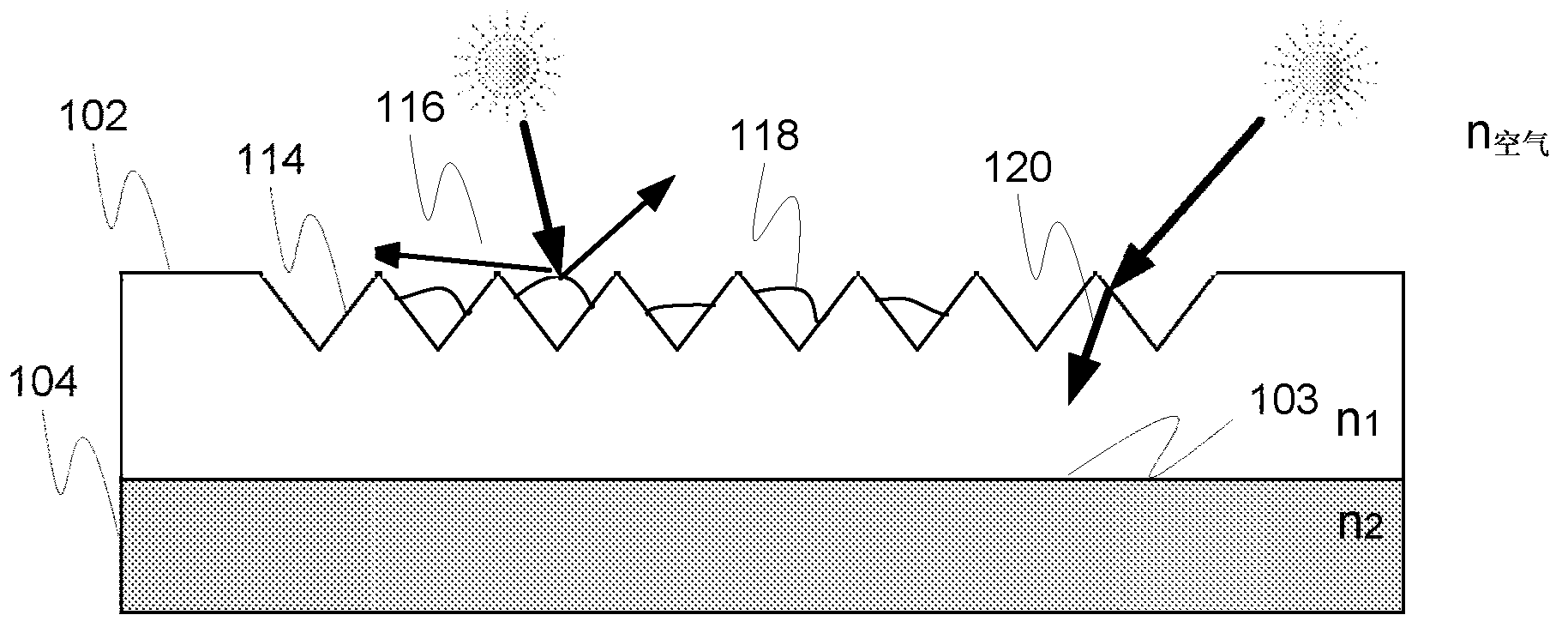

[0067] Figures 1a and 1b have already been introduced in conjunction with the description of the background art.

[0068] The principles of the invention can be employed in a variety of use cases and scenarios. For example, the scenario may involve the use of visible light, infrared light and / or ultraviolet light.

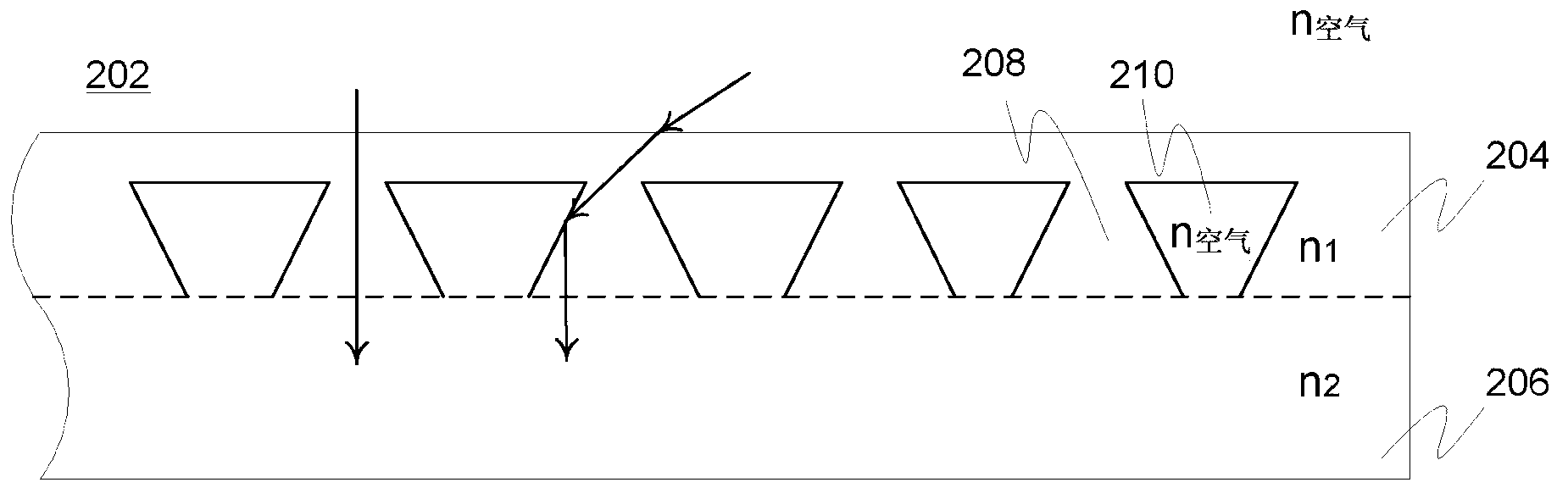

[0069] In some embodiments of the invention, laminated structures may be made from large elements such as large panels or membranes. These elements may be provided with optical patterns that have a desired optical function, such as a coupling (eg incoupling or outcoupling) function. Patterns with smaller surface relief forms may be used, eg grating, binary, flared, oblique and / or trapezoidal forms. Essentially any of a discontinuous pattern (eg, raster pixels, small recesses) or a continuous form, elongated recesses or channels, two-dimensional or three-dimensional may be used. It is preferred to have at least a small flat part, ie contact surface, on the laminati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com