Rotary type interlayer large sized soup cooker

A rotary and interlayer technology, which is applied in the direction of utensils with enlarged heating surfaces, heating devices, cooking utensils, etc., can solve the problems that the heating temperature cannot be adjusted, the delicious food cannot be normally provided, and the food cannot be boiled, etc., so as to prevent Effects of Air Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings. However, if the specific description of the corresponding known technology or structure conflicts with the gist of the present invention, the detailed description will be omitted.

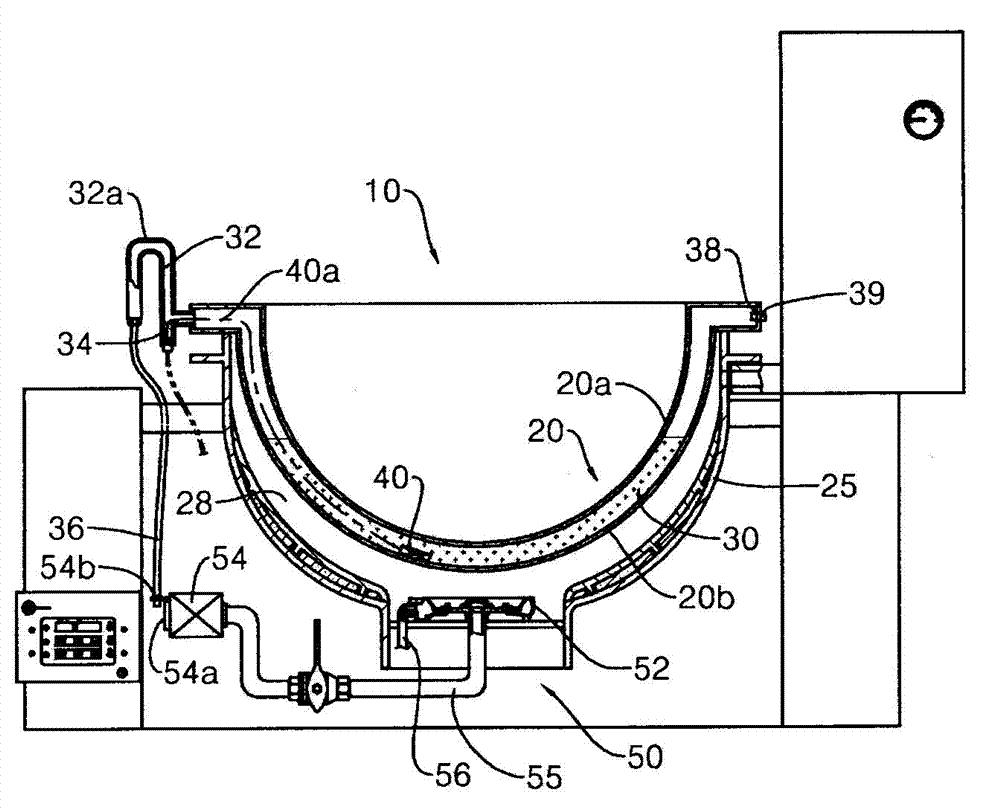

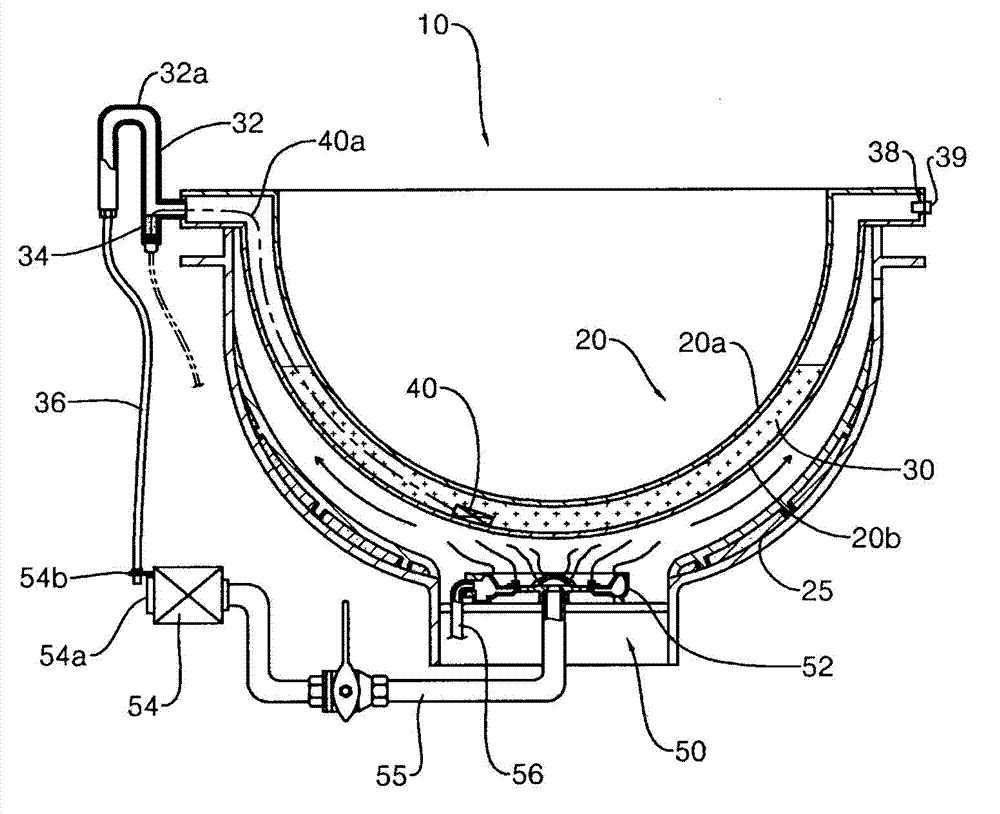

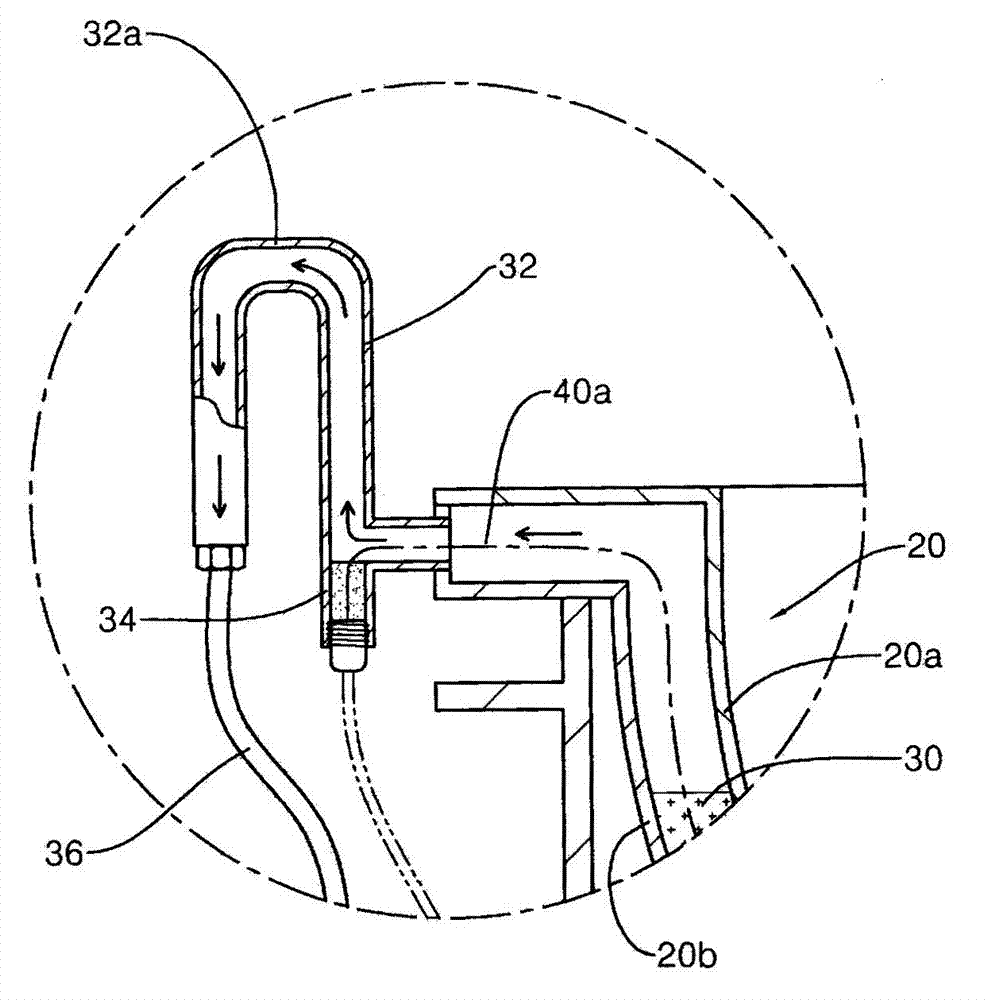

[0026] The present invention takes the hemispherical large-scale pot body 10 used by schools and corporate canteens, cooking with the inner layer pot 20 of the flame heating pot body 10 as an example, including the inner and outer walls 20a, 20b of the inner layer pot 20 of the pot body 10 The interlayer cavity 30 formed between and capable of injecting heat medium oil is installed on one side of the upper part of the interlayer cavity 30 so that the air in the interlayer cavity 30 can be dredged so that the air vent 38 and the corresponding switch 39 that can be easily injected into the heat medium oil are installed. The other side of the upper part of the cavity 30 is installed with a heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com