Changing device for engine break-in test and clamping mechanism for exhaust tube of changing device for engine break-in test

A technology of clamping mechanism and exhaust pipe, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of complex connection structure, large labor intensity and working time of workers, and reduce the test efficiency of engine running-in test, so as to improve the installation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

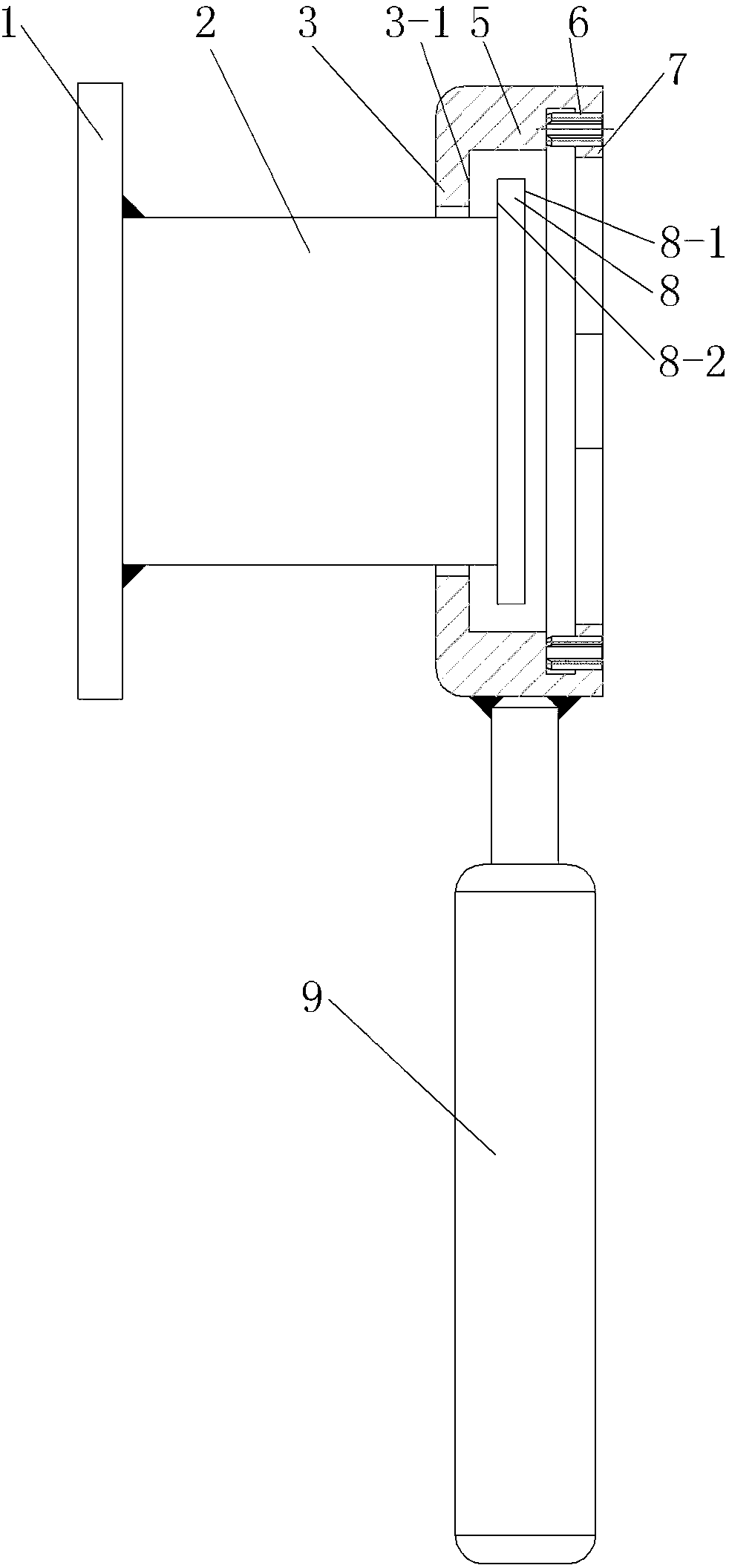

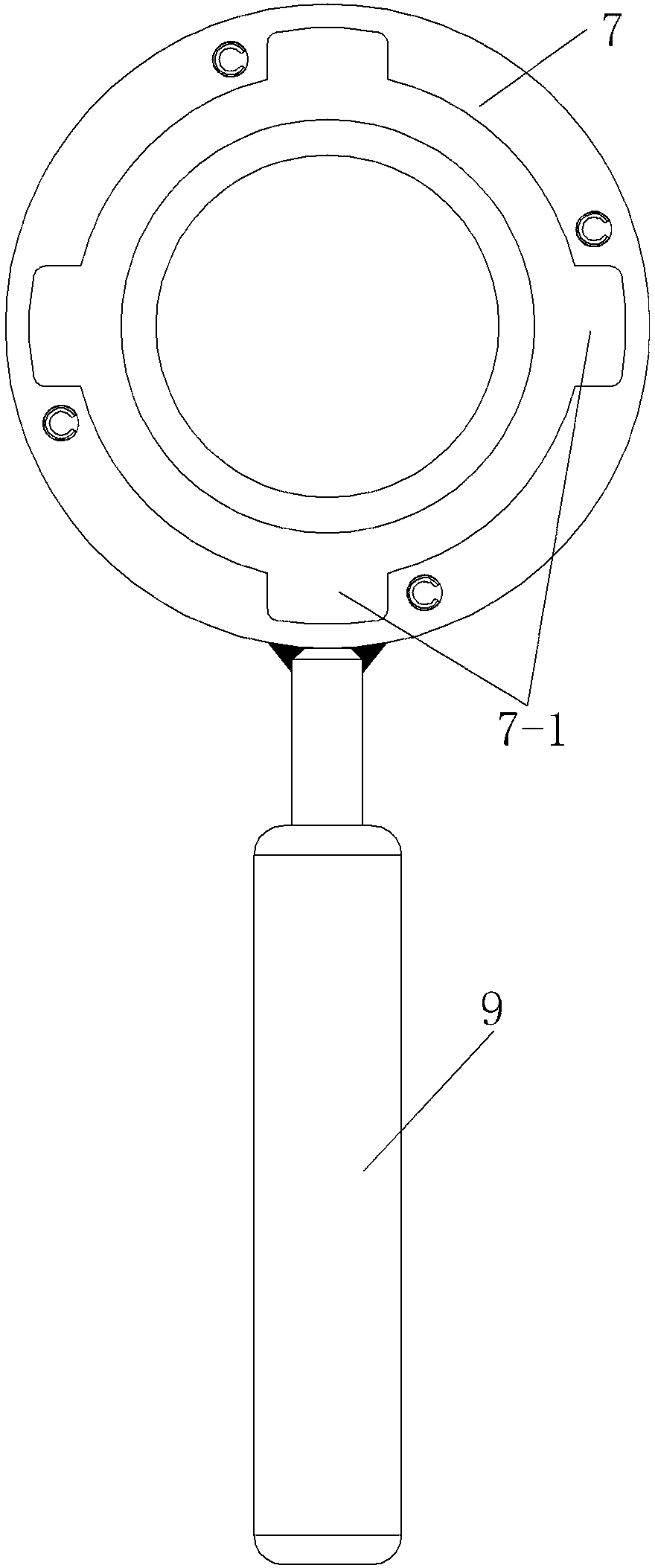

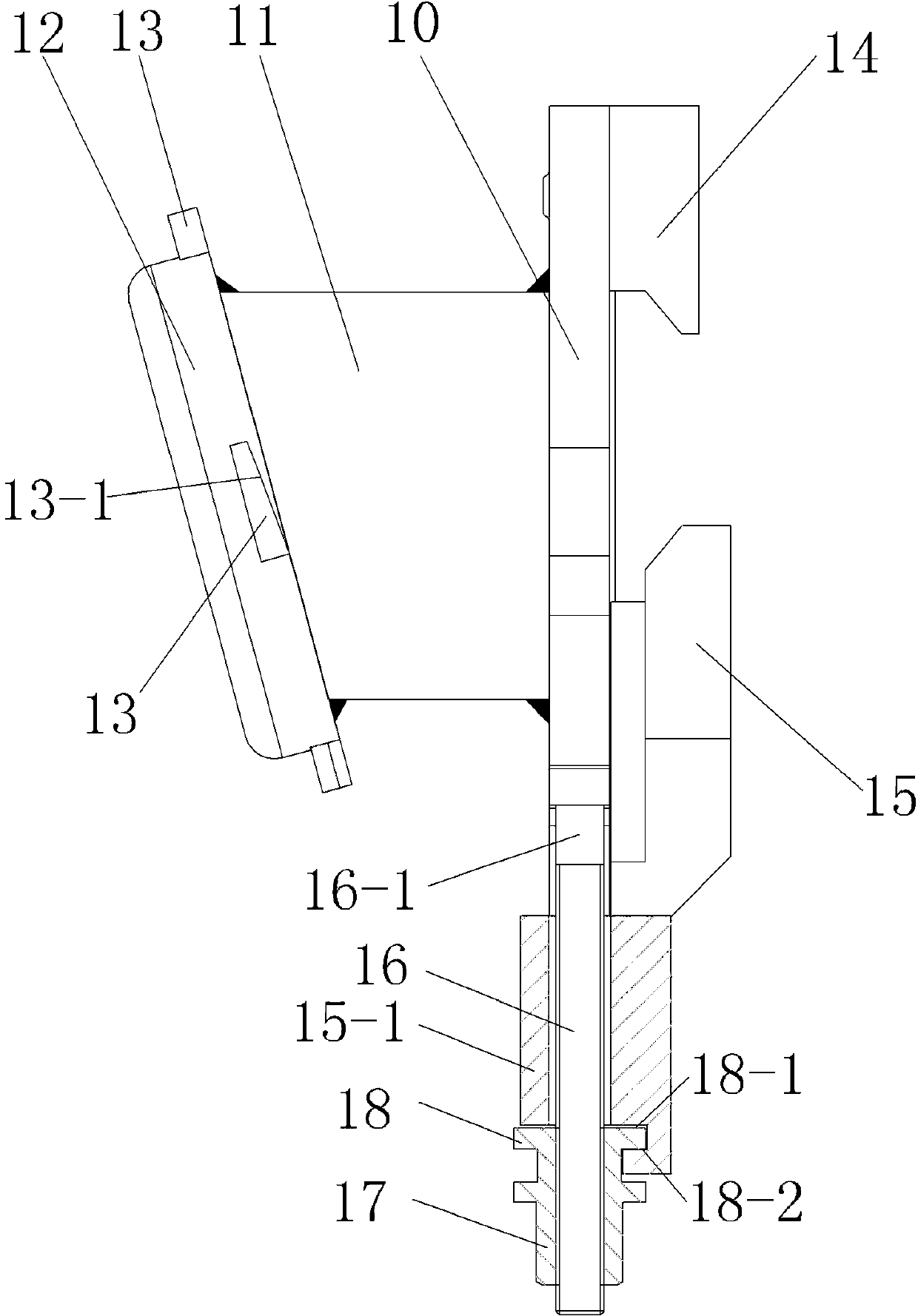

[0029] Examples of replacement devices for engine break-in tests are Figure 1~11Shown: including the clamping mechanism for the exhaust pipe and the disassembly mechanism for disassembling the clamping mechanism. Wherein the clamping mechanism includes a connecting body, and the connecting body includes a connecting plate 10 and a clamping mechanism pipe 11 arranged at the lower end of the connecting plate 10, and the connecting plate 10 is provided with an inner hole of the clamping mechanism pipe 11 and a discharge pipe of a corresponding exhaust pipe. Connecting holes for gas channels to communicate with each other. The upper end of the connecting plate 10 is provided with a movable jaw 15 and a fixed jaw 14 arranged forward and backward along the radial direction of the connecting hole, and the connecting plate 10 is provided with an installation groove 10-1 whose groove depth extends along the front-to-back direction, wherein the installation groove 10-1 The middle wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com